The infusion process step by step.

What is the infusion?

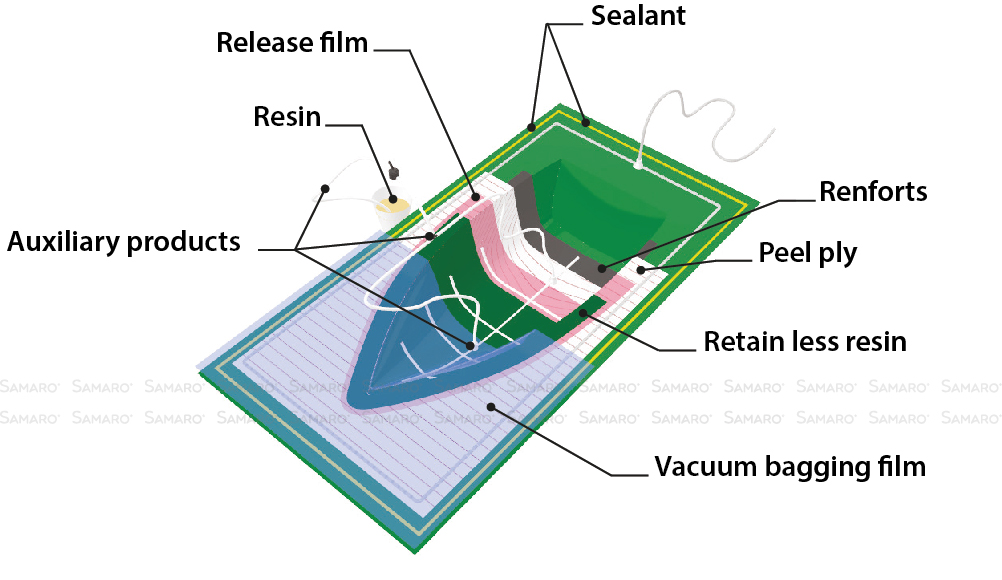

The infusion consists of dry stacking the different layers of fibres (on the GelCoat or not) inside the rigid mould and vacuum packing the whole assembly with the help of a hermetic membrane.

The layers are impregnated by the migration of the resin sucked in by vacuum along a drainage channel.

This process allows a higher fibre volume rate (60% compared to 40% in contact moulding), better protection of the operators while maintaining the possibility of producing large parts.

Below is a schema describing the infusion process for a boat hull mould:

Composite resin systems for infusion

| Property | ||

|

Araldite® LY1564 / Aradur® 3486 | Araldite® LY 1564 / Aradur® 3486 is laminating system with low viscosity and high flexibility. |

|

Araldite® LY1564 / Aradur® 3487 | Araldite® LY 1564 / Aradur® 3487 is laminating system with low viscosity and high flexibility. The reactivity may easily be adjusted to demands through the combination of both hardeners. |

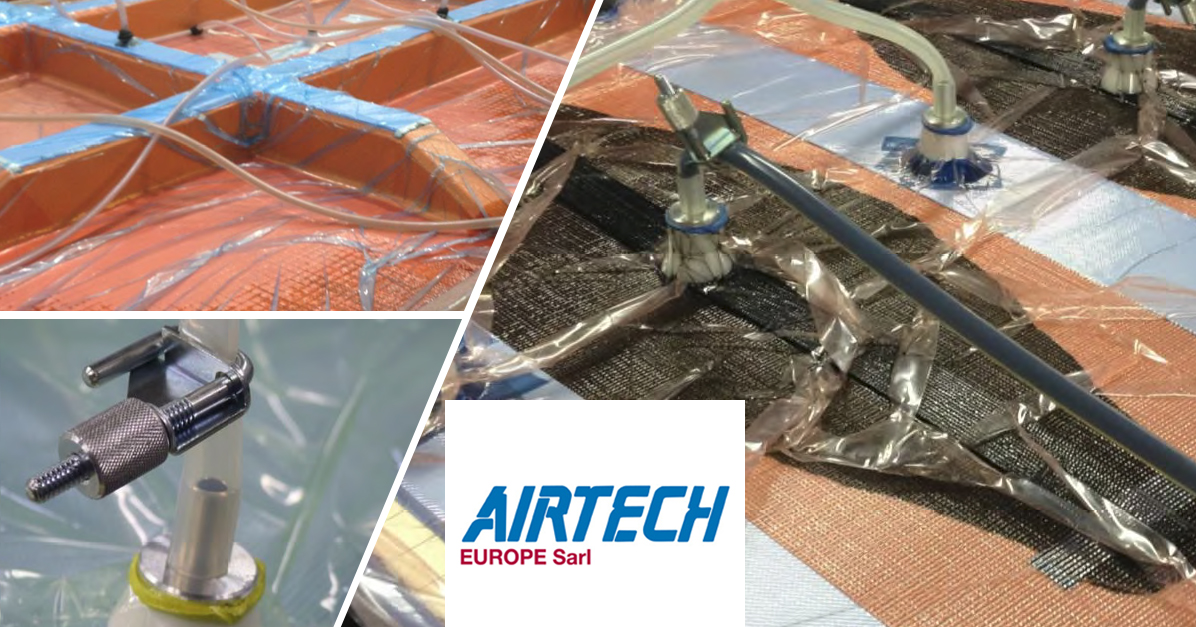

Vacuum devices for infusion – Airtech auxiliary products.

Airtech Advanced Materials Group is the leading manufacturer and supplier of vacuum bagging products in the field of composite materials. Airtech is a supplier to major players in the aerospace, aeronautics, automotive, wind energy, motor sport and other markets.

| Peel ply | ||

|---|---|---|

| Applications | ||

|

Airtech®Econostitch® G | L’Econostitch® is an economical peel ply with good performance when used with both polyester and epoxy resins |

|

Airtech®Econostitch® | L’Econostitch® is a nylon peel ply with red tracers which make this peel ply more visible before and after a cure, reducing the possibility of the peel ply being left on the part |

| Release films | ||

|---|---|---|

| Applications | ||

|

Airtech® Wrightlon 3900 NP | Is a high elongation release film (500%) with excellent release properties. Ideal for compacting applications. |

|

Airtech® Wrightlon 5200 B P3 | Is a release film with good elongation and temperature resistance (260 ° C). It is easy to remove and allows the manufacture of complex shapes. |

| Retains less resin | ||

|---|---|---|

| Applications | ||

|

Airtech®GreenFlow 185 | Is a economical retains less resin very used in infusion process |

|

Airtech®Knitflow 160 | Knitflow 160 is designed to assist resin flow through the part during the vacuum assisted resin infusion process |

| Vacuum bagging film | ||

|---|---|---|

| Applications | ||

|

Airtech®Big Blue | The Big Blue L100 is a multilayer vacuum film available in wide width. It is economical and mainly dedicated to infusion. |

|

Airtech®KM 1300 | The Ipplon® KM1300 is a high elongation vacuum film. Excellent for prepreg molding or autoclave infusion. |

| Sealants | ||

|---|---|---|

| Applications | ||

|

Airtech®Cordon butyl AT200Y | AT200Y from Airtech is a sealant with excellent adhesion. It is ideal for composite applications up to 204 ° C. |

|

Airtech®Airseal®2 | Is an economical sealant. It is recommended in composite applications at low and medium temperatures (up to 150°C). |

| Auxiliary products | ||

|---|---|---|

| Applications | ||

|

Airtech®Raccord nylon cannelé en “T” | Nylon Barb T Fitting |

|

Airtech®Raccord nylon cannelé coudé | Nylon Barb Elbow Fitting |

|

Airtech®Resin infusion connector RIC 1/2 | The Airtech Resin infusion connector (RIC) provides inexpensive and efficient through bag connection for use with spiral tube vacuum manifold and resin feed lines for low temperature resin infusion application |

|

Airtech®Barb fitting infusion valve | Barb Fitting Infusion Valve |

|

Airtech®Poly spiral | Tubing for resin feed and vacuum connections. Can be easily cut and connected with range of coupling, elbow and T fittings. |

|

Airtech®Poly tubing | Spiral tubing for resin feed lines and vacuum manifolds around part edge. Can be easily cut and connected with range of coupling, elbow and T fittings |

|

Airtac®2 LH+ |

Is a spray adhesive designed for temporary bonding. Airtac 2 LH can be used to hold dry materials on contours and vertical surfaces.

|