Preventing electric vehicle recalls: make the right choice for your connectors

Automotive industry

The automotive industry continues to be at the forefront of technological developments and serves as a guide for many other industries. The most recent developments in the automotive market have focused on electronic advancements, from improving the driver and passenger experience through an improved human-machine interface (HMI) to critical safety developments and semi-autonomous driving features such as automatic braking and driver lane keeping assistance, for example.

Today, the focus is on moving away from the internal combustion engine to environmentally friendly alternatives, including the electric vehicle (EV) and various hybrid options (HEV), and this shift brings even more challenges for electrical circuits, connectors and contacts.

Lubricants for electrical contacts

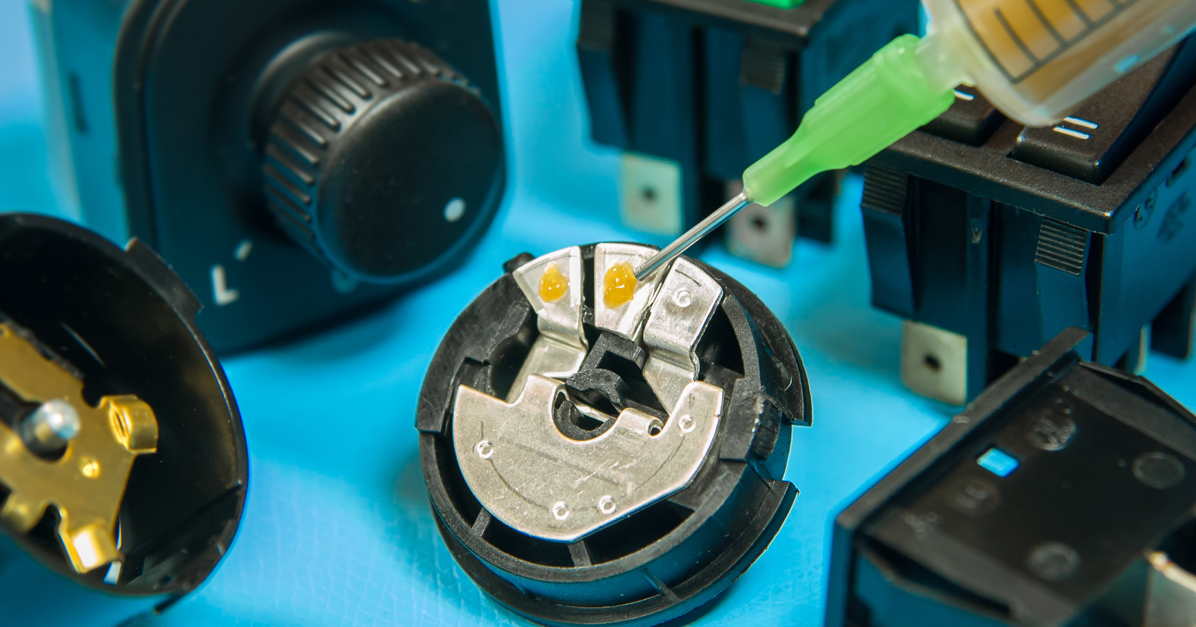

Regardless of industry, electrical contact lubricants are used to improve the performance and reliability of electrical contacts and connectors. Originally invented in 1941 by the founder of Electrolube to improve the electrical performance and reliability of volume controls, the use of contact lubricants has spread to many different industries and has been a key factor in the reliability of automotive components for decades.

Contact lubricants are specially formulated greases and oils designed to reduce friction and wear and improve the electrical performance of current-carrying metal interfaces, such as those found in switches and connectors. Since no metal interface is completely uniform and smooth, when applied to these surfaces as thin films, they fill in any surface imperfections, improving contact and electrical performance and extending contact life by reducing hot spots, fretting and arcing.

By filling the air spaces between contacts, contact lubricants greatly increase the effective surface area, thereby preventing arcing, temperature rise and the resulting formation of oxides. They also provide a barrier against air contamination and reduce the effects of friction by facilitating smooth movement. In addition, the use of contact lubricants is generally evaluated for its “feel” characteristics, improving the quality of movement of a switch or simple plastic-to-plastic contacts, for example.

Whether it’s interior components such as air conditioning ventilation flaps, exterior components such as side mirror adjustments, or critical contacts within the wiring harness, the applications for contact lubricants continue to grow as CASE (Connected, Autonomous, Shared, Electric) technologies advance.

Contact lubricants are used in three main ways in automotive applications:

1. Improve electrical transfer and contact reliability

As we have already seen, contact lubricants increase contact areas by filling gaps and reducing electrical resistance. The technology has expanded to more safety-critical operations in vehicles, and with the increase in automotive recalls due to electronic components, it is imperative that these safety-critical connections are maintained properly. In a recent report by AlixPartners, it was stated that recalls to correct electronic or electrical system failures have increased by 30% annually in recent years. These failures include software and software integration issues, but the vast majority of recalls are actually due to failures related to integrated electrical components. As an IATF 16949 approved electrochemical solutions provider, Electrolube is often called upon to help prevent such problems and fully understands the impact that such failures can have on businesses, with costs coming from all areas, including the effect on brand reputation for the car manufacturer. It is therefore extremely important that all aspects of electronic systems are considered, including the connection between devices and the correct selection of a contact lubricant.

Traditionally, improvements in the electrical properties of switches and connectors in vehicles have been focused on low-voltage general purpose switches, before moving to more critical applications as electronics applications developed. With the move to electric vehicles, a new set of challenges has arisen, including more electrical connections and, more importantly, much higher voltages being transferred into the vehicle. With experience in areas such as medium and high voltage switchgear, electroplating and relays, Electrolube has a range of products to meet the new requirements of the electric vehicle market.

2. Reduce the effects of external influences by reducing corrosion and wear.

Acting as the vehicle’s central nervous system, the wiring harness contains numerous connections to facilitate the communication of a multitude of devices. Due to the complexity of electronic applications in a vehicle, the wiring harness also represents a significant amount of weight. This has led to the use of different materials, such as aluminum, and in some cases, different metals can be used in the same harness. While reducing weight, other problems with using aluminum include the formation of hard oxide layers and electrochemical corrosion in the presence of moisture and dissimilar metals. Contact lubricants can be used to protect freshly mated contacts that are exposed to environmental conditions, but this is only part of the problem. Using a contact lubricant to prevent exposure of any base material on contacts or aluminum parts can significantly reduce contact and connector failure rates.

Environmental influences can include temperature changes, exposure to moisture and corrosive atmospheres. Temperature changes can affect the consistency of the contact lubricant, for example, a lubricant may have a cone penetration value of 320 at 25 ̊C but when exposed to temperatures of -40 ̊C or lower, this value can significantly decrease, resulting in a much harder grease consistency. Wet environments are also common, and most contact lubricants will withstand high humidity for extended periods of time. When high humidity is combined with corrosive environments, differences between products can be realized. Electrolube has designed a series of tests to illustrate these differences and provide additional assistance in proper product selection. These tests include moisture wetting tests, followed by salt spray tests, chlorine resistance tests and consideration of different contact materials.

The combined moisture and salt spray test subjected the lubricants to 90% moisture at 35 ̊C for 3 weeks, followed by one week at 35 ̊C in the salt spray chamber. The protection of the copper and steel substrates was visually assessed after this test. Generally, synthetic lubricants, such as Electrolube CTG, provided the best protection in this environment. In addition to this test, gold and silver contacts protected by various lubricants were also subjected to the salt spray environment. The results reinforced the previous findings, highlighting that some mineral-based lubricants in particular are not suitable for protecting these materials in harsh environments. Finally, as an extreme test, an oxidizing environment containing chlorine was created and maintained at 35 ̊C for 2 months and the results again showed that Electrolube CTG provided exceptional protection, followed closely by Electrolube CG53A and CG60.

3. Improve the quality, feel and strength and operation of connectors and switches.

Contact lubricants are also widely used in many applications to improve the “feel” of a switch, giving a high quality impression. This is also true for many applications inside vehicles, ensuring that metal-to-metal, plastic-to-metal and plastic-to-plastic contacts have a good connection between parts, reducing noise and movement when subjected to vibrations caused by normal vehicle operation. With the move toward quieter vehicles, improvements in tire technology and the future of electric vehicles, the interior of vehicles is a much quieter place and as such, the quality of these contacts and overall noise dampening are critical to ensuring a high quality driving experience.

Products such as Electrolube’s CG60 and SPG have been used for many years in these types of automotive applications and are suitable for protecting the interior of vehicles, ensuring the highest level of driving comfort. In some cases, a fluorinated lubricant, such as Electrolube’s EGF, may be required to provide better performance in these areas, especially to reduce insertion stresses when mating connectors. With the number of electronic components and connectors increasing as we move toward electric vehicles, the need for lubricants such as CG60, CTG or Electrolube’s EGF to improve manufacturing and in-use protection also increases significantly. In fact, a study by Research and Markets indicates that, on a component basis, the connection of electronics inside vehicles via wiring harnesses is expected to grow the fastest through 2025 due to the development of advanced automotive technologies, including driver assistance systems and safety features.

The automotive industry is undergoing a period of constant change and evolution. The shift to hybrid and electric vehicles poses new challenges for electrical connectors, switches and devices, which will continue to evolve in the years to come. Developments in battery technology and user interfaces, alternative fuel sources and the ever-expanding autonomous driving market will all add to these challenges. By tackling the seemingly small task of ensuring high-quality, reliable and protected connections, contact lubricants will help meet these new demands. The EV powertrain is on average two and a half times more expensive than conventional powertrains (AlixPartners), making cost another barrier to growth in this market. This cost will naturally decrease over time due to economies of scale and technology improvements. This, combined with the reduction in overall costs resulting from maintaining high quality levels and the reduction in vehicle recalls due to connector failures, is why manufacturers must have contact lubricant selection at the top of their development agendas now and for many years to come.

More info :

Need more information on contact lubricants or on our partner Electrolube ?

Contact our technical department at +33 426 680 680 or fill in our contact form.

Vous pouvez aussi télécharger nos guides de sélection dédiés aux lubrifiants de contact :

Source : DGE-EUROPE