MOLYKOTE® P-3700 Anti-Seize Paste

A direct response to market needs and trends

Threaded connections in high-temperature applications, such as turbines or turbochargers, require proper lubrication to prevent seizure and provide adequate tightening torque.

MOLYKOTE® P-3700 Anti-Seize Paste

- Ensures controlled friction during assembly

- Facilitates loosening of threaded connections after long periods at elevated temperatures.

- It is environmentally and health friendly – no hazard labeling or precautionary statements.

- Contains no intentional chromium-based ingredients

- Significantly reduces the formation of hexavalent chromium when used at 300°C+ on high chromium alloys.

- Contains no calcium or magnesium ingredients.

Benefits and performance

- Significantly reduces hexavalent chromium formation when used at 300°C+ on chromium containing alloys

- Wide service temperature range: -30°C to 900°C

- Excellent heat resistance: Fully functional anti-seize property up to 900°C; higher temperatures have not been tested.

- Provides a controlled coefficient of friction during assembly, promoting accurate tensioning.

- Very good load capacity: 4 ball test of ~3000 N

Reliable and safe operation of gas and steam turbines and turbochargers

Sustainability features

- Provides decades of durable performance, allowing maintenance after long periods at elevated temperatures to minimize material usage and waste.

- Offers a very favorable EHS profile (no hazard symbols) while providing high performance under stress.

- Prevents the formation of hazardous substances (Hexavalent Chromium Cr(VI) ), even in high temperature applications.

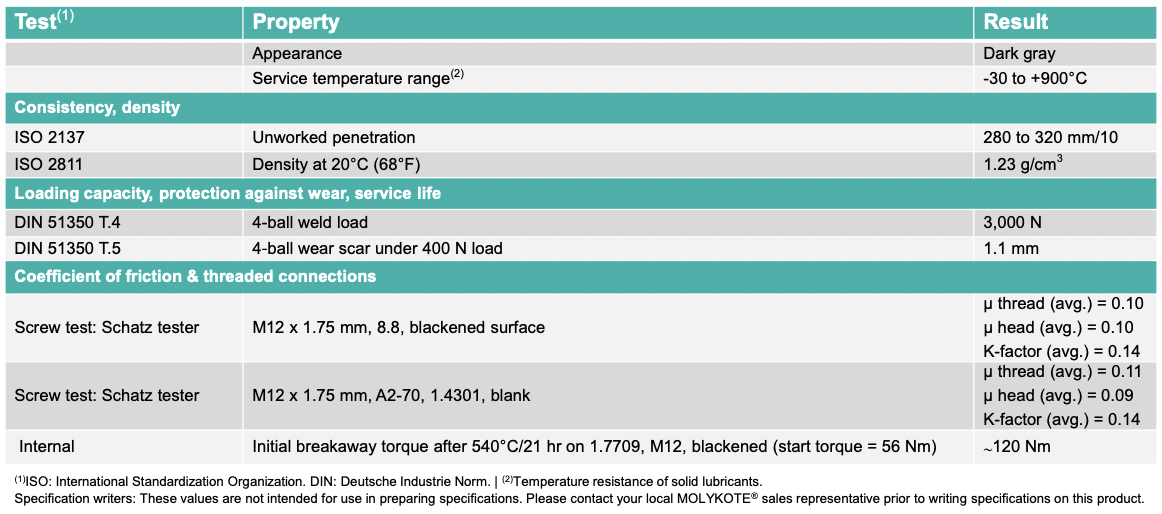

Technical information

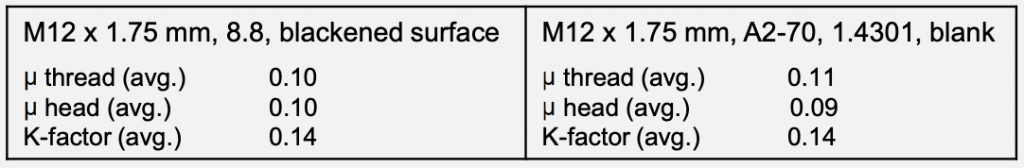

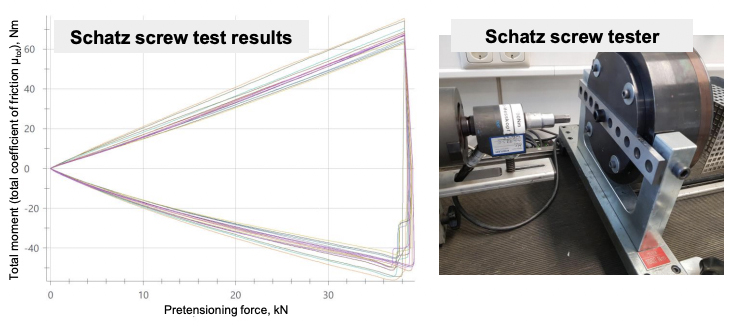

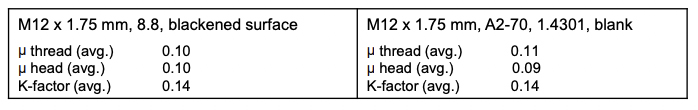

Screw testing

MOLYKOTE® P-3700 anti-seize paste provides consistent, repeatable forces over multiple tightenings (5), regardless of screw type.

The new MOLYKOTE® P-3700 anti-seize paste successfully suppresses the formation of yellowish hexavalent chromium at high temperatures while providing a fully functional anti-seize property.

P-3700 was designed primarily for gas/steam turbine applications. Here, temperatures above 900°C are very unlikely, if at all. Higher temperatures have not been tested.

Technical data

Product overview

Key features

- Excellent anti-seize properties, even after exposure to 900°C

- Controlled friction during assembly, allowing exact tensioning.

- High purity paste

Benefits for customers

- Significantly reduces Cr(VI) formation when used on high chrome alloys at T >300°C

- Threaded connections are easy to loosen after long periods at high temperatures

- Environmentally and health friendly – currently without hazard pictograms.

- Worldwide availability

More info

If you would like to know more about the MOLYKOTE® P-3700 or the MOLYKOTE® range, please contact our technical department on +33 426 680 680 or fill in our contact form.