MOLYKOTE® HP-300 protects the sensitive electrical connectors of the inverter.

MOLYKOTE® HP-300 grease protects the essential electrical connections of the inverter.

Application

Electric vehicles rely on AC/DC inverters to convert the direct current (DC) electrical output of the vehicle’s battery into alternating current (AC) to power the engine and other components. These batteries provide 500 volts of power and a maximum current of 500 amps. Reliable operation of the inverter is therefore essential to protect the life of the battery and the vehicle’s engine.

The challenge

Power cables with O-rings made of different rubbers – including EPDM or silicone rubber – are used to connect the inverter and the battery. O-rings are essential to prevent moisture from entering the inverter chamber. With working temperatures of up to 120°C, high temperature performance and appropriate rubber-compatible lubrication are required to protect the O-rings from damage.

A Chinese automotive manufacturer contacted the MOLYKOTE® team to find a solution that would provide the necessary O-ring protection and performance, as well as reliable rubber compatibility.

Solution

MOLYKOTE® HP-300 grease can protect O-rings in electrical connections in harsh environments with minimal hardening or change in mechanical properties. Offering excellent rubber compatibility, performance and thermal stability, this grease can be used with a variety of rubbers, such as EPDM elastomers and silicone rubbers.

Using EPDM elastomers and silicone rubbers, the MOLYKOTE® technical team has subjected the MOLYKOTE® HP-300 grease to several tests to observe how the lubricant performs under pressure, successfully demonstrating the grease’s performance through laboratory comparisons with a traditional lubricant solution as a control. The MOLYKOTE® HP-300 grease had no negative effect on the mechanical properties of the rubber O-rings and showed excellent compatibility. This data convinced the car manufacturer that MOLYKOTE® HP-300 grease was the ideal solution to their challenge.

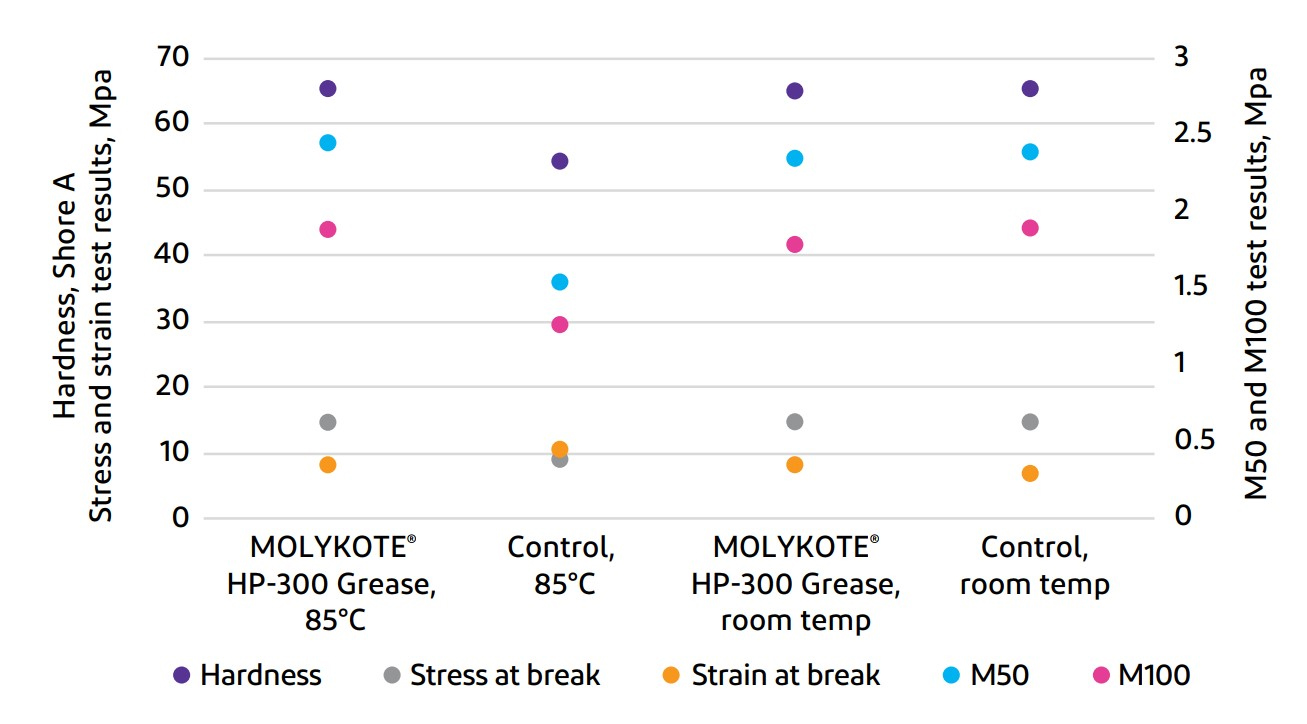

Compatibility testing of EPDM elastomers

The samples were prepared according to ISO 527 and aged for 250 hours at 85°C and room temperature.

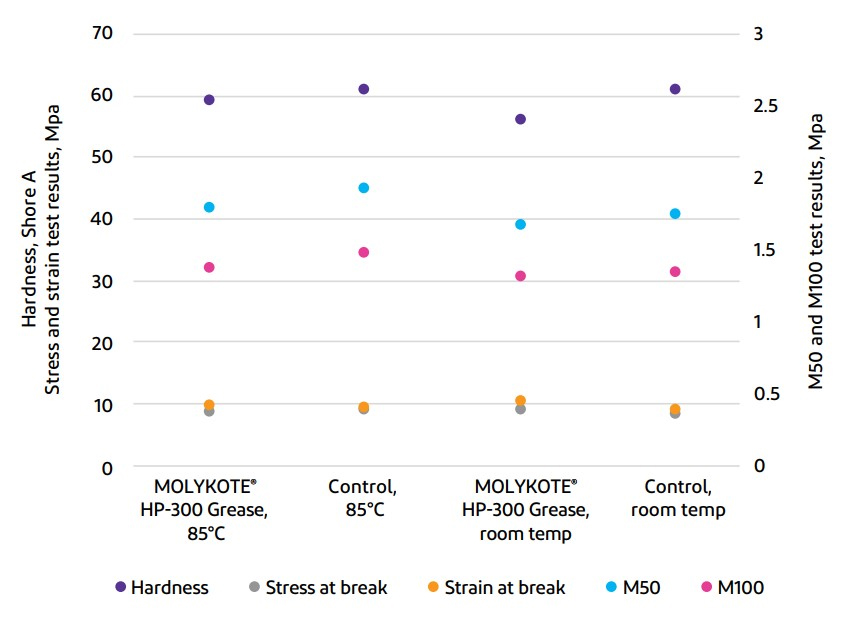

Compatibility testing of silicone rubbers

Samples were prepared according to ISO 527 and aged for 250 hours at 85°C and room temperature.

Achieve extraordinary performance in extreme conditions

MOLYKOTE® HP-300 grease can be widely used in harsh conditions such as high and low temperatures, corrosive environments, solvents, liquefied natural gases and high vacuum conditions, etc. It has been used in specialized applications where lubricant volatilization is not desirable, such as on clean room equipment and semiconductor manufacturing equipment.

It has been used in specialised applications where volatilisation of the lubricant is not desirable, such as on clean room equipment and semiconductor manufacturing equipment.

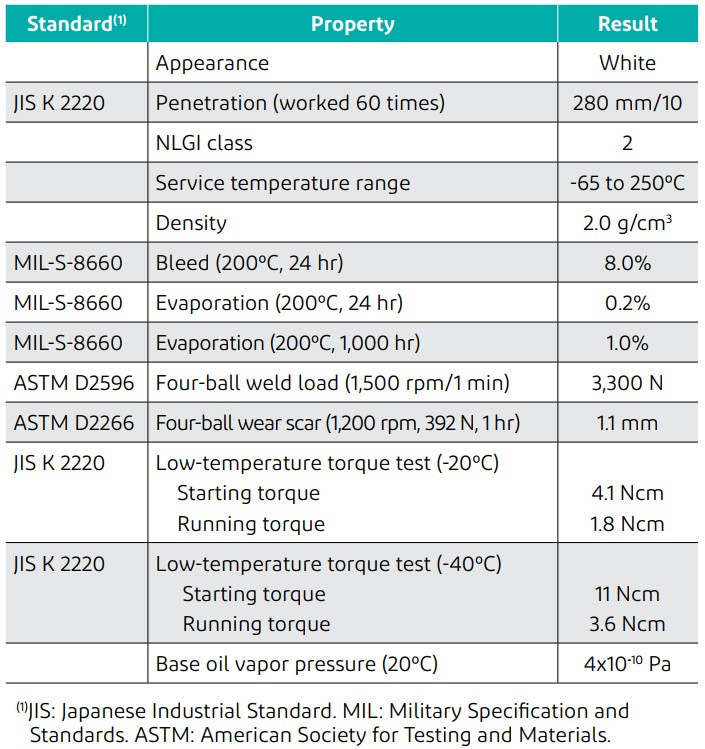

MOLYKOTE® HP-300 grease has the following characteristics:

- Good compatibility with plastics and rubber

- Excellent high temperature stability

- Superior chemical and solvent resistance

- Minimal oxidation damage; suitable for long-term lubrication.

- Low vapour pressure (base oil)

Typical characteristics of MOLYKOTE® HP-300 grease

Note: These values are not intended to be used for the preparation of specifications.

Source: MOLYKOTE case study

More informations :

Need information about MOLYKOTE® HP-300 grease or MOLYKOTE® lubricants ? Contact our technical servici at +33 426 680 680 or fill in our contact form.

You can also download our selection guide dedicated to industrial lubrication and maintenance :