MOLYKOTE ™ D-9100 : Effective lubrication to reduce friction and control noise, stick-slip and wear

MOLYKOTE™ D-9100 Anti-Friction Coating (EN) : Anti-Friction for Rubber and Plastics

- Flexible lubricant coating withstands parts elongation

- High productivity and processing speed with UV curing

- Dry lubricant film formed without heat damage or long drying times

- Effective for many types of rubber and thermoplastics like o-rings

- Excellent adhesion can extend lubricant coating service life

Adhesion

Good adhesion provides good lubrication properties for rubber and plastics parts for prolonged periods of time. Molykote™ D-9100 Anti-Friction Coating has strong adhesion to many types of rubber and plastic and flexibility to follow mechanical movement.

UV Curable

With a water-based carrier and UV curing system, Molykote™ D-9100 Anti-Friction Coating can be applied to many types of rubber and plastic without potential damage from heat or chemical solvents. In addition, the UV cure system reduces cycle time and energy cost compared to the heat cure system.

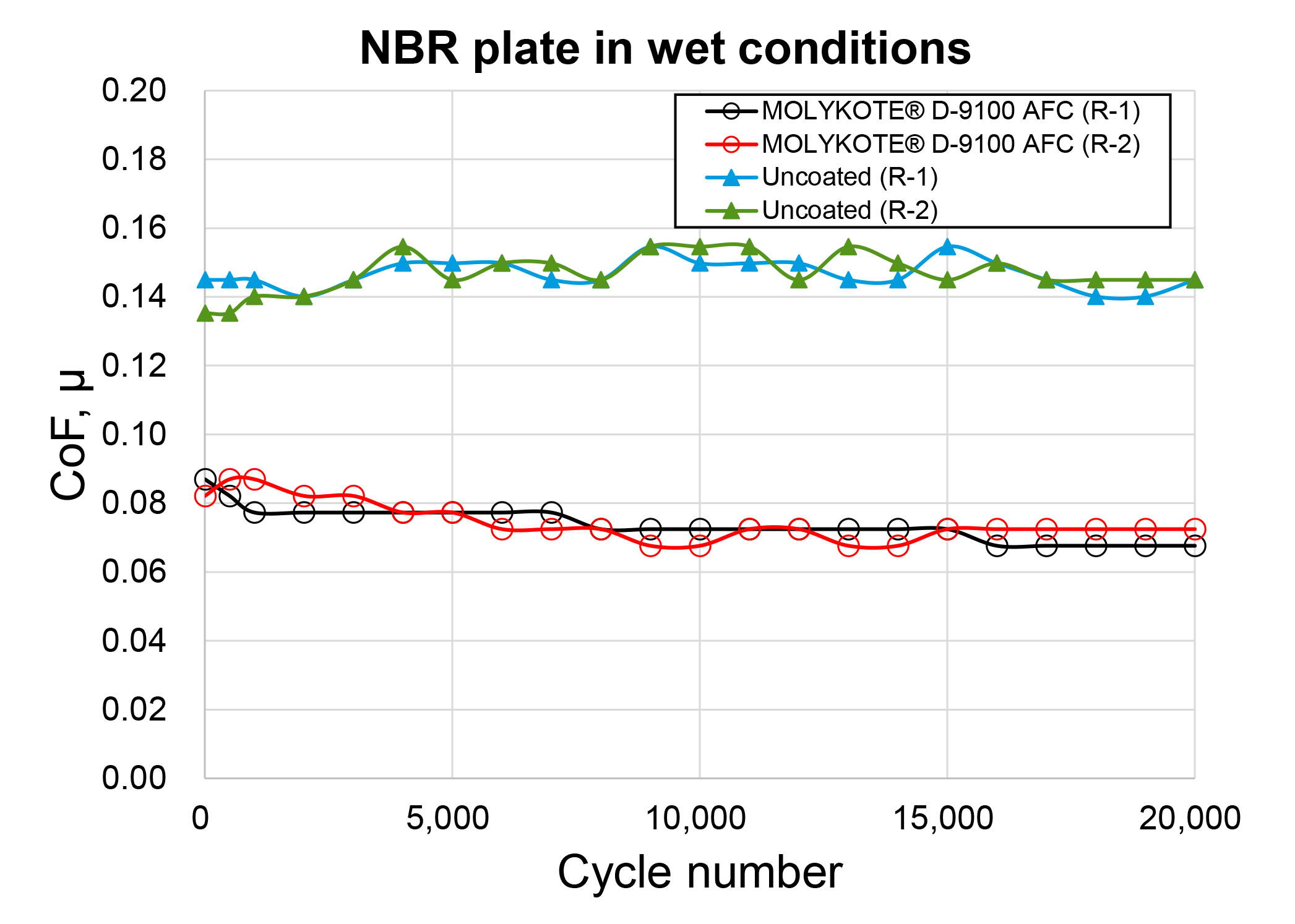

Lubricity

Rubber materials have a high coefficient of friction that makes it difficult to have consistent lubrication. MOLYKOTE D-9100 Anti-Friction Coating can reduce coefficient of friction and suitably lubricate dynamic rubber seals and sliding plastic parts. With fast UV curing, it also can improve productivity in assembly processes. Molykote™ D-9100 Anti-Friction Coating can extend the life of sliding parts and highly stressed parts that have a high wear problem.

More informations :

Need information on MOLYKOTE® lubricants ? Contact our technical department on +33 426 680 680 or fill in our contact form.

Download the new selection guide for Molykote® anti-friction coating:

You can also download our selection guide dedicated to industrial lubrication and maintenance: