Lubrication solutions for threaded connections

DuPont Molykote® Lubricants

For over fifty years, OEM designers, maintenance engineers and materials engineers around the world have relied on the Molykote® brand for performance and lubrication expertise. Molykote lubricants, formulated for extreme loads and environments, are also ideal for standard lubrication. They offer additional benefits over conventional lubricants, including:

- Longer component life

- Longer lubricant life

- Extended maintenance intervals

- Reduced maintenance time and costs

With technical centres worldwide, our products can reach you wherever you are to provide Smart Lubrication™.

Improving the performance of threaded connections

Threaded connections offer benefits such as convenient disassembly, reuse and accurate reassembly. However, without proper lubrication, these benefits can be compromised, leading to equipment challenges and reliability issues.

Lubrication prevents problems such as:

- Inconsistent friction coefficients, leading to uneven bolt tensioning

- Stick-slip

- Stress corrosion cracking

- Fretting

- Galling

- Seizing

Molykote® lubricants help your threaded connections perform well, from initial assembly to repeated disassembly. They are designed to withstand harsh conditions, a wide range of temperatures and the effects of heavy loads and contaminants.

The benefits of effective lubrication

Lubricants reduce friction and wear, protect against corrosion and dissipate heat. The use of carefully selected lubricants helps prevent common failure mechanisms associated with threaded connections. The key functions of good lubrication are :

- Provide a constant coefficient of friction (µ)

- Minimise the complexity of achieving appropriate preload forces and torque specifications

- Reduce fatigue failure rates through stability to temperature and load variations

- Form protective barriers

- Prevent scaling of threaded surfaces

- Provide protective coatings on mating surfaces

- Reduce fretting, corrosion, galling and shearing

- Reduce exposure to corrosive environments

MOLYKOTE® ANTI-SEIZE PASTES PROVIDE A CONSTANT COEFFICIENT OF FRICTION

| PRODUCT NAME | µt | µc | K* |

| MOLYKOTE® G-n METAL ASSEMBLY PASTE/SPRAY | 0.078 | 0.085 | 0.15 |

| MOLYKOTE® G-n PLUS PASTE | 0.12 | 0.06 | 0.14 |

| MOLYKOTE® G-RAPID PLUS PASTE/SPRAY | 0.10 | 0.06 | 0.13 |

| MOLYKOTE® 1000 PASTE/SPRAY | 0.13 | 0.08 | 0.17 |

| MOLYKOTE® M-77 PASTE | 0.12 | 0.12 | 0.20 |

| MOLYKOTE® P-37 PASTE | 0.142 | 0.091 | 0.18 |

| MOLYKOTE® P-40 PASTE | 0.16 | 0.08 | 0.18 |

| MOLYKOTE® P-74 PASTE | 0.117 | 0.078 | 0.16 |

| MOLYKOTE® P-1900 PASTE / SPRAY | 0.10 | 0.10 | 0.17 |

| MOLYKOTE® U-n PASTE | 0.11 | 0.11 | 0.18 |

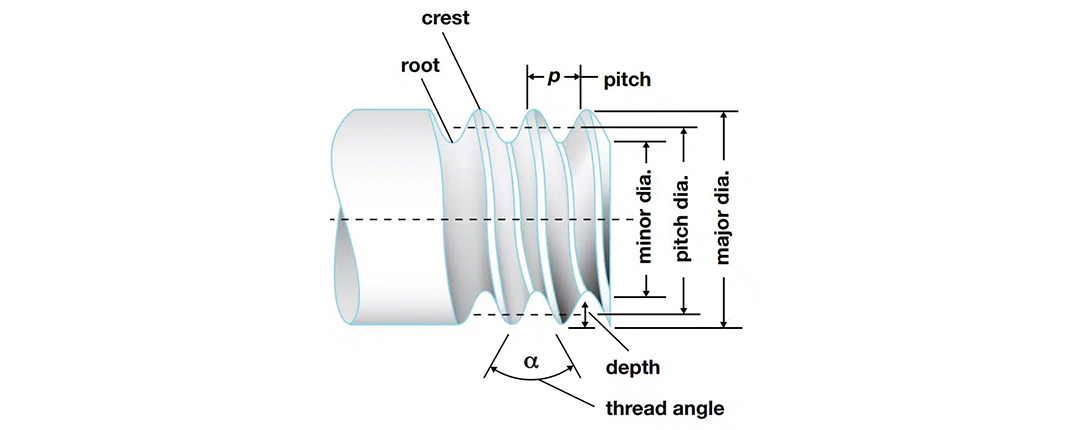

Tightening torque

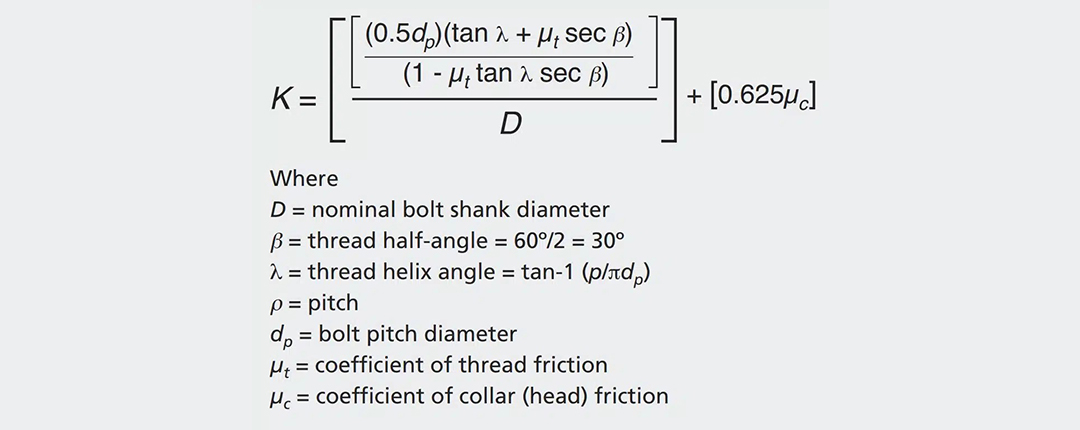

Adequate torque is required to achieve proper bolt tension and elongation. The torque must overcome all sources of friction before elongation can occur. Thread and bolt head friction can be reduced and held constant by the addition of a lubricant.

Calculations of the torque required for correct bolt elongation are based on the geometry of the threaded fastener and the friction of the thread and bearing surfaces. The friction factor applied to the torque calculations is known as the K factor. The friction coefficients of the thread and bolt head are used to calculate the K factor. It is therefore through lubrication that friction and K-factor can be controlled to ensure correct bolt tension and elongation for a derived torque value.

During assembly, torque energy is first consumed to overcome friction. The remaining energy is consumed by the elongation of the bolt (which provides the clamping force). In the absence of adequate lubrication, too much torque is used to overcome friction, resulting in insufficient bolt elongation.

K-factor formula

Defined failure mechanisms

Unequal coefficients of friction (µ)

- High µ of contacting surfaces (head, nuts, shank and threads) can lead to increased twisting of the fastener and reduced clamping force.

- A low µ of the surfaces in contact can lead to excessive elongation of the bolt

Adhesive sliding

The difference between static friction and kinetic friction when two surfaces are in contact

Stress corrosion cracking

At high temperatures, sulphur diffuses into the interstices of joints, creating high stress points. The sulphur then combines with the nickel (in alloy steels) to form sulphide crystals. These crystals grow, increasing stress and creating larger cracks.

Contact wear

Vibration causes the oxide layers to wear, and the particles clog the internal spaces, leading to seizure.

Abrasion

Sliding detaches the oxide layer from the threaded materials, the roughness is transferred and destroys the surface and the coating.

Seizure

Oxide-free surfaces become cold-welded under extreme pressure, preventing disassembly.

Not all lubricants are created equal

Different by design

Greases, anti-seize pastes and anti-friction coatings are formulated to meet different challenges and keep equipment running smoothly.

Greases contain high concentrations of base oils to create the lubricating film between surfaces. Anti-seize pastes and anti-friction coatings are formulated differently. The base oil in these materials simply carries the high concentration of solid lubricants directly to the point of lubrication. These solid lubricants do not evaporate, ensuring effective lubrication even under high temperatures and pressures.

For durable assembly and disassembly of threaded connections, the lubricant must remain in place, even in harsh environments. Molykote® anti-seize pastes and anti-friction coatings offer effective long-term solutions. These lubrication solutions form a protective layer between threaded surfaces, facilitating assembly and disassembly while protecting against wear and corrosion.

Greases are designed to purge base oils for lubrication, but in threaded connections the lubricant may not be able to withstand the high load and the base oil may evaporate, reducing the life of the grease.

Molykote anti-seize pastes contain a high concentration of solid lubricants, offering protection against abrasion, fretting corrosion, slippage, seizure and damage. They offer corrosion protection, water washout resistance and a consistent coefficient of friction. These solid lubricants stay in place, even at high temperatures and under heavy loads.

Anti-friction coatings are paint-like products that form a slippery film on the surface, optimising friction control even under extreme conditions. Their effectiveness and service life are highly dependent on the pre-treatment of the component surface, such as degreasing, phosphating, sandblasting and anodising.

Typical properties of solid lubricants used in anti-seize paste and anti-friction coating formulations

By combining different types of solid lubricants in paste formulations, we achieve increased protection against fretting corrosion, improved load carrying capacity and wear prevention. The combination of these lubricants offers more than they do individually.

| Graphite | Molybdenum disulphide (MoS2) | Polytetrafluoroethylene (PTFE) | Copper | White solids |

| High temperature stability | High load-bearing capacity | Colourless | High load-bearing capacity | Protects against fretting corrosion |

| Good lubricant in wet conditions | Wide temperature range | Low load-bearing capacity | High temperature stability | Suitable for high temperatures |

| Low coefficient of friction at high loads | Excellent adhesion | Low coefficient of friction at low loads | Should not be used with stainless steel at temperatures above 1000°C (1832°F) | Excellent adhesion |

| Protects against fretting corrosion | Protects against fretting corrosion | Good chemical resistance | Can promote galvanic corrosion | |

| Friction decreases with increasing load | Good reduction in sliding friction | |||

| Prevents sticking and sliding | ||||

| Should not be used in damp environments |

Anti-seize pastes

Molykote® anti-seize pastes are high performance products specially formulated for extreme conditions, creating and maintaining a lubricating layer despite high loads and temperatures. They offer:

- Wear protection

- Reliable performance over wide temperature ranges

- Constant coefficient of friction (µ)

- Resistance to water washout

- Protection against corrosion

- Immediate lubrication on application and long-term lubrication

Anti-seize pastes can be applied by brushing or dispensed pumping, and some are available in sprays.

Anti-friction coatings

Molykote® anti-friction coatings are ideal for parts exposed to dusty or inaccessible environments, providing long-term lubrication. Parts can be pre-lubricated in a clean environment to reduce handling during field assembly operations.

Molykote® brand AFCs (Anti-Friction Coatings) are formulated to offer these benefits when cured:

- Dry lubrication

- Non-flammable coating

- Film does not attract dirt and dust

- Extra protection against corrosion

- Long-term lubrication without evaporation

- Effective lubrication even after extended service life

Application methods include spraying, dipping, centrifuging, brushing and roller coating.

Is dry lubrication necessary?

If your application is exposed to dust, dirt and debris, Molykote® antifriction coatings are recommended. If not, choose Molykote® anti-seize pastes.

Can your part be thoroughly cleaned and dried?

If so, choose Molykote® anti-friction coatings. If not, choose Molykote® anti-seize pastes.

Select the right lubricant

The Molykote anti-seize pastes and anti-friction coatings (AFCs) featured in this brochure are specially formulated for use on threaded connections, ensuring long-term protection, reliability and productivity.

Anti-seize pastes do not require extensive surface preparation, while anti-friction coatings require thoroughly cleaned and dried surfaces. Used together, Molykote® anti-seize pastes and AFCs can offer synergistic performance.

You can use the following tables to select the Molykote lubricant that best meets your needs. For more information and technical specifications please contact us.

Selection table for Molykote anti-seize pastes

Using anti-seize pastes is one of the best ways to reduce and control friction in threaded connections, ensuring long-term performance and easy disassembly and reassembly. To determine the appropriate anti-seize paste, consider the load, environment, temperature and speed of your application. Below is a general description of the Molykote anti-seize pastes that DuPont considers most suitable for threaded connections.

|

1 Temperature range of solid lubricants |

||||||||||

| PRODUCT NAME | MAIN FEATURES | TEMP. RANGE (in °C) | SOLID LUBRICANTS | High adhesion capacity | Composition metal-free | Prevention against fretting corrosion | Protection against fretting corrosion | Water resistance | High load capacity | Suitable for low to moderate loads |

| MOLYKOTE® G-n METAL ASSEMBLY PASTE/SPRAY |

|

Up to 400¹ | White solids, MoS2 | ✓ | ✓ | ✓ | ||||

| MOLYKOTE® G-n PLUS PASTE |

|

Up to 400 | MoS2, graphite, white solids | ✓ | ✓ | ✓ | ||||

| MOLYKOTE® G-RAPID PLUS PASTE/SPRAY |

|

Up to 400 | MoS2, graphite, white solids | ✓ | ✓ | ✓ | ||||

| MOLYKOTE® 1000 PASTE/SPRAY |

|

-30 to 650 | Copper and graphite, white solids | ✓ | ✓ | ✓ | ||||

| MOLYKOTE® M-77 PASTE |

|

Up to 350¹ | MoS2 | ✓ | ✓ | |||||

| MOLYKOTE® P-37 PASTE |

|

-30 to 1400¹ | Zirconium dioxide | ✓ | ✓ | ✓ | ||||

| MOLYKOTE® P-40 PASTE |

|

-40 to 1200¹ | White solids and PTFE | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| MOLYKOTE® P-74 PASTE |

|

-40 to 200 | Graphite and white solids | ✓ | ✓ | |||||

| MOLYKOTE® P-1900 PASTE / SPRAY |

|

-30 to 300 | White solids | ✓ | ✓ | ✓ | ✓ | |||

| MOLYKOTE® U-n PASTE |

|

Up to 400¹ | MoS2 and white solids | ✓ | ✓ | |||||

Molykote® brand Anti-Friction Coating (AFC) Selection Chart.

The use of an AFC is one of the best ways to reduce and control friction in threaded connections, ensure long-term performance and facilitate disassembly and reassembly. When determining the appropriate AFC, remember to consider the service requirements, the desired coating method and the specific benefits of different applications. Below are general descriptions of the Molykote AFCs that DuPont considers most suitable for threaded connections.

| PRODUCT NAME | MAIN CHARACTERISTICS | TEMP. RANGE (in °C) | SOLID / BINDING LUBRICANTS | High load | Chemical resistance | Fuel and oil resistance | Contact corrosion | Corrosion resistance |

| MOLYKOTE® 3402-C ANTIFRICTION COATING |

|

-200 to 310 | Solids: MoS₂ Binder: proprietary | ✓ | ✓ | ✓ | ✓ | |

| MOLYKOTE® D-708 ANTIFRICTION COATING |

|

-64 to 240 | Solids: PTFE Binder: epoxy | ✓ | ||||

| MOLYKOTE® D-7409 ANTIFRICTION COATING |

|

-70 to 300 | Solids: MoS₂ Binder: polyamide-imide | ✓ | ✓ | ✓ | ✓ | ✓ |

| MOLYKOTE® 3400A ANTIFRICTION COATING / SPRAY |

|

-200 to 260 | Solids: MoS₂ Binder: epoxy | ✓ | ✓ | ✓ | ✓ | |

| MOLYKOTE® D-321R ANTIFRICTION COATING / SPRAY |

|

-200 to 260 | Solids: MoS₂, graphite Binder: titanate | ✓ | ✓ | |||

| MOLYKOTE® 106 ANTIFRICTION COATING |

|

-70 to 250 | Solids: MoS₂ Binder: epoxy | ✓ | ✓ |

Source: Molykote Technical Documents