Introducing Molykote®D-6600 Anti-Friction Coating – New PTFE coating

A durable new option for treating metallic components in challenging automotive applications : Molykote®D-6600

Performance Advantages of Molykote® D-6600

• Excellent dry lubrication properties

• Low coefficient of friction for metal/plastic pairings, especially at medium and low pressures

• Excellent load-carrying capacity at low and medium pressures

• Excellent wear protection

• Excellent adhesion to metals

• Good corrosion protection

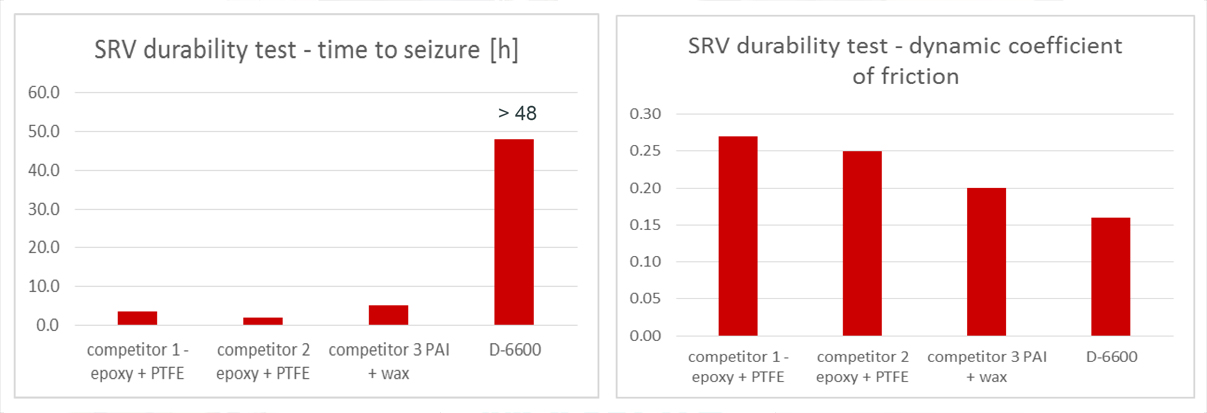

SRV tribometer durability testing – low pressure

Steel vs steel, linear contact

Low pressure = 100 N/mm2 (45 N), speed 0.32 m/s

Surface pre-treatment = blasting

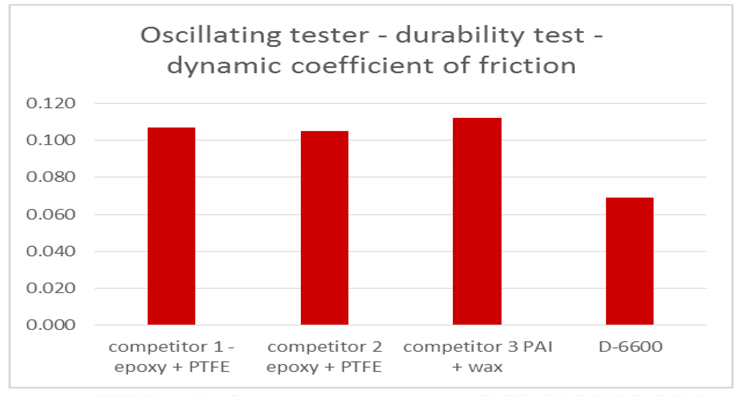

Metal plastic durability testing

Anti-Friction Coating coated steel vs POM plastic

Low pressure = 75 N/mm2, speed 5 cm/s

| Potential Applications | |

|---|---|

|

Permanent lubrication of metal/metal and metal/plastic pairings involving: – Slow to medium-fast movements – Medium- to low-pressure conditions |

| Potential Applications | |

|

Metal coatings in automotive chassis, body, brake segments |

| Potential Applications | |

|

Starter motor lubrication |

| Potential Applications | |

|

Metal parts such as door locks |

| Potential Applications | |

|

Metal/plastic contacts such as ball joints and window lifters |

| Potential Applications | |

|

Where oils or greases cannot be used for technical reasons or are undesirable because of the risk of soiling |

More information

Contact our technical service : by mail or by phone : +334 26 680 680