Improving thermal management for power electronics: the key role of Dow silicones

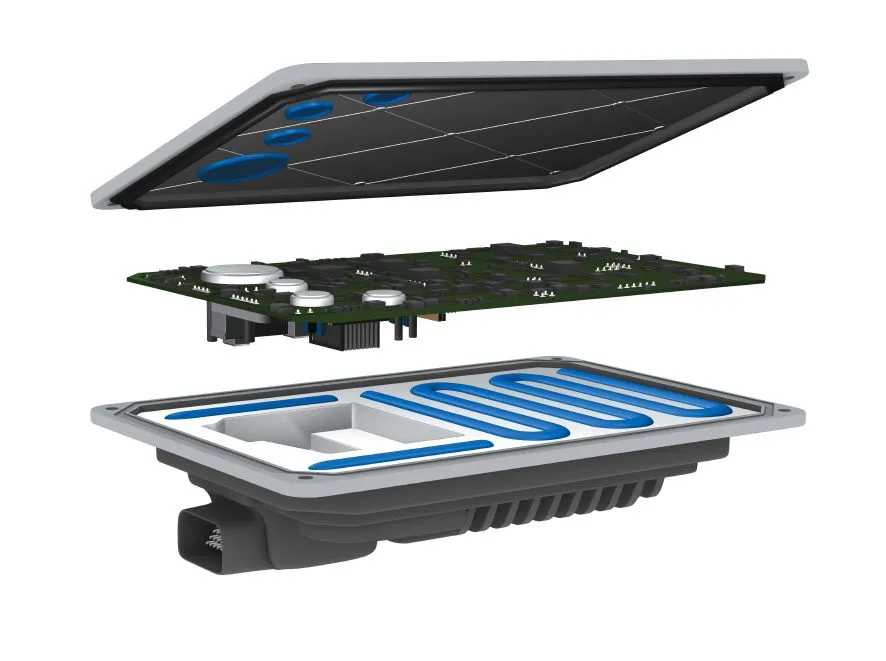

In today’s power electronics devices world, thermal management has taken on crucial importance. This is due to higher voltages, higher operating temperatures, faster switching, and more compact designs. Battery packs must deliver more power and longer range through better thermal management. Advanced thermal interface materials (TIMs) play a key role in efficiently dissipating heat, increasing power density, and improving the reliability of power modules and batteries.

Batteries provide more power and have a larger range, requiring better thermal control.

Selecting the Right TIM for the Best Performance

Selecting the ideal thermal gap filler for batteries or gel for inverters, converters, onboard chargers, and electronic control units hinges not solely on performance, but also on the simplicity of application. Uniform, dependable application with limited maintenance of the equipment is pivotal to maintaining a high standard of quality and minimizing system expenses.

On the other hand, conventional TIMs can present certain obstacles in terms of application, such as:

- Pauses for maintenance to substitute the application extrusion head due to severe abrasion resulting from the TIM.

- Gradual phase separation that might lead to issues with pumping and impact the balance of mixtures.

- Potential quality complications when the TIM isn’t adequately suited to the specific equipment and its ultimate application.

Dow’s Silicone Innovation for Thermal Management

Dow’s silicone-based thermal management materials address all these dispensing issues. The company’s formulation success is based on close collaborations between Dow experts and leading equipment vendors to tailor material properties for consistent, reliable, fast, and easy dispensing.

Efficient Heat Management and Dependability for High-Power Density Semiconductors

Apart from collaborating with equipment producers, Dow runs internal laboratories that are fitted with prevalent application systems. This enables their scientists and researchers to fine-tune and verify their formulations. Semiconductors with the highest power density necessitate proficient heat diffusion and enhanced reliability. Dow’s thermally conductive silicones can be utilized in slender layers or crafted with a low-viscosity formulation to entirely fill irregularly shaped gaps, thereby creating extensive contact areas for optimum heat transfer.

Innovation is a key driver for elevating the thermal management of present-day power electronic devices.

Customized TIM Solutions for Power Modules and Batteries

Dow provides a variety of TIMs specifically designed for power modules and batteries. Notably, the Dowsil™ TC 4060 GB Thermal Gel and the Dowsil™ TC-4525 CV Thermally Conductive Gap Filler, among their offerings, are especially appropriate for the inverters, converters, and onboard chargers employed in electric vehicles (EVs).

Collaboration for Achieving Success in Thermal Management

Samaro, in cooperation with Dow, supports customers in the battery and power electronics industries in accomplishing their thermal management objectives by working together throughout the application lifecycle.

To sum up, Dow, through its Dowsil™ product line, provides a multitude of sophisticated silicone-based solutions and backing services to enhance thermal management performance, facilitate dispensing, and fulfill application demands. At Dow, fostering innovation is fundamental in delivering enhanced thermal management to contemporary power electronics devices.