How to glue glass to metal? With cyanoacrylate glue Born2Bond Light Lock HV

To ensure optimum bonding of glass or metal, it is essential to carefully prepare the surface of the materials to be bonded before any application.

With this in mind, Samaro and its partner Socomore recommend the use of Diestone DLS. This cleaning and degreasing agent, which contains no chlorinated hydrocarbons, evaporates quickly, providing optimum surface preparation for effective glass and metal bonding.

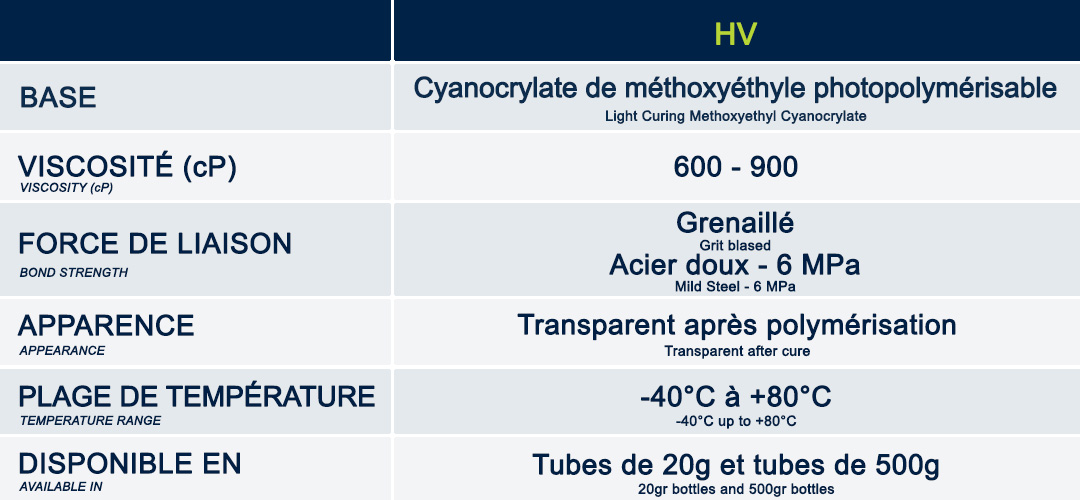

The industrial bonding of materials such as glass and metal represents a constant challenge for engineers and manufacturers, requiring high-performance, versatile adhesive solutions. In this context, Born2Bond Light Lock HV cyanoacrylate adhesive stands out as the solution of choice, offering a unique combination of technical advantages and specific properties that meet the most demanding requirements of the most demanding industrial sectors.

Technical benefits of Born2Bond Light Lock HV :

Unique dual cross-linking formulation:

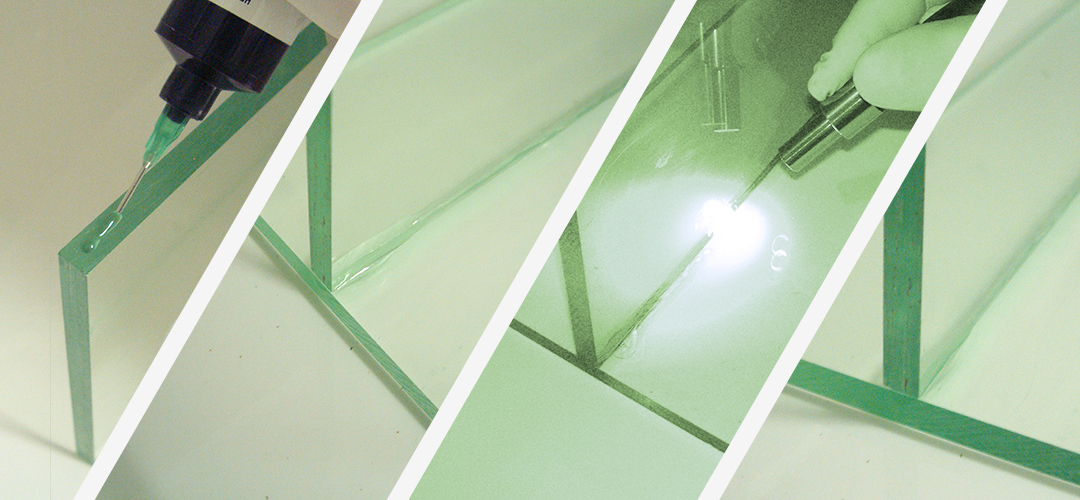

Born2Bond Light Lock HV is distinguished by its ability to cure both under UV exposure and/or in contact with materials. This dual polymerisation guarantees ultra-fast (between 5 and 60s) and complete curing, ensuring a strong, durable bond between materials, even when bonding glass.

Low odour and low blooming:

Unlike many traditional cyanoacrylate adhesives, Born2Bond Light Lock HV has minimal odour, providing a more pleasant working environment. What’s more, its low blooming reduces the risk of unwanted residue forming around the bonding area, ensuring impeccable aesthetic results.

ISO 10993 approved:

Born2Bond Light Lock HV is ISO 10993 compliant, ensuring full biological evaluation and optimum safety for sensitive applications in the medical and pharmaceutical industries.

Wide temperature range:

With an operating temperature range from -40°C to 80°C, Born2Bond Light Lock HV offers reliable adhesion in a variety of environmental conditions, ensuring consistent performance and good resistance to temperature fluctuations.

Ultra-fast curing:

Born2Bond Light Lock HV offers ultra-fast curing, with a set time of just 60 seconds at room temperature. This time is reduced to 5 seconds with UV exposure, enabling increased productivity and faster production cycles.

Applications in various industrial sectors:

Bottling industry:

Born2Bond Light Lock HV has extensive applications in thebottle industry, including glass bonding (bottles, flasks) and metal bonding (metal components) in the production of perfumes and cosmetics. Its translucent colour after polymerisation ensures impeccable aesthetics, while its ultra-fast curing enables an efficient, seamless production process.

Electronics industry:

In the electronics industry, Born2Bond Light Lock HV is used forelectronic assembly, coating andencapsulation of sensitive electronic components such as an LED. It offers reliable adhesion to a variety of substrates, including glass and metal. Its ability to cure under UV exposure allows instant curing, ensuring effective protection against moisture and other contaminants.

Medical industry:

For medical applications such as theassembly of medical devices and the bonding of glass and metal components in medical equipment, Born2Bond Light Lock HV offers a reliable and secure solution. Its compliance with ISO 10993 ensures optimum biological compatibility, while its rapid cure enables efficient manufacturing processes and reduced time-to-market.

Curing conditions and application techniques :

To achieve optimum results with Born2Bond Light Lock HV, it is essential to observe certain curing conditions and apply the appropriate techniques:

Immediate assembly of components:

Assembly of the components must be carried out immediately after application of the adhesive to ensure optimum bonding. Any delay may compromise the effectiveness of the bond.

Single-component use:

Born2Bond Light Lock HV is a single-component adhesive, which means it is ready to use without prior mixing. This feature simplifies the application process and ensures consistent results.

Setting time:

Born2Bond Light Lock HV offers an ultra-fast set time of 60 seconds at room temperature, allowing final adjustment of parts before full cure. For glass bonding, or if your application permits, exposure to UV light reduces the fixing time to just 5 seconds, offering unrivalled speed in production processes.

In conclusion, Born2Bond Light Lock HV cyanoacrylate adhesive offers an innovative, high-performance adhesive solution for bonding glass and metal in a variety of industrial applications. With its unique dual cure, compliance with the stringent ISO 10993 standard, and ultra-fast curing capability, it is a first choice for manufacturers and engineers looking to optimise the efficiency and quality of their production processes.