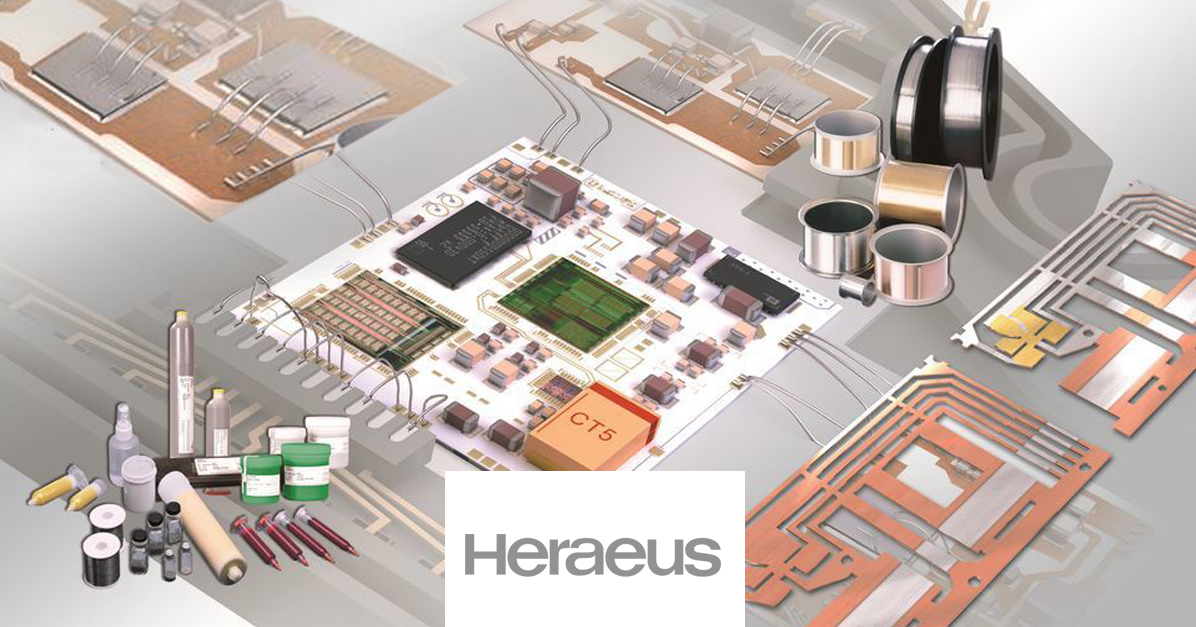

Heraeus: Innolot, the high-performance alloy for the automotive industry

Innolot makes it possible to produce high-performance welds for the harsh conditions of the automotive industry.

Extreme environmental constraints and increased demands on the performance of electronic components require optimized solutions.

The reliability of the solders connecting ceramic components to epoxy substrates is highly dependent on the thermal expansion of both materials.

Ceramic components have relatively low coefficients of thermal expansion (CTEs), while PWB materials based on epoxy glass have comparatively high CTEs.

When a circuit assembly increases in temperature, the board expands much more than the component welded to it.

The offset expansion places shear stresses and deformations on the welded joints. After repeated cycles, the joints begin to show signs of fatigue, cracks begin to propagate, and the initial joint strength degrades – sometimes to complete failure. Conventional SAC alloys are not able to meet these requirements.

The Innolot alloy improves reliability in applications using both standard and elevated operating temperatures.

Operating temperatures up to 150°C are possible.

Main benefits HERAEUS F 645 Innolot-89M3 :

- Improved reliability, even under difficult conditions, especially in automotive applications

- Innolot significantly improves the creep resistance of welds

- Reliable weld seam even at operating temperatures up to 150°C

- Without cleaning

More informations :

Do you need information about our range of Heraeus? Contact our technical department on +33 426 680 680 or fill in our contact form.

- Available in 500 g jar

- Technical data sheet,

- Fiche de donnée de sécurité