Guide: Find the right VOLTALEF® gas contact lubricant for your application!

To guarantee optimum lubrication, it is essential to carefully prepare the surface of the materials to be lubricated before any application.

With this in mind, Samaro and its partner Socomore recommend the use of Diestone DLS. Diestone DLS is a fast-evaporating, chlorinated hydrocarbon-free cleaner and degreaser that provides optimum surface preparation for effective lubrication.

When it comes to lubrication in environments involving gas, choosing the right lubricant is crucial to ensuring that equipment runs smoothly and operations are safe. In this guide, we’ll look at the various types of lubricant suitable for contact with gas, the relevant approvals and specific industrial applications.

Which lubricants should I choose for gas contact?

When selecting a lubricant for an application involving gas, it’s essential to opt for products specially formulated to withstand the rigorous conditions of these environments. Fluorinated lubricants, such as those based on PFPE (perfluoropolyether), are often favored for their excellent chemical stability, resistance to extreme temperatures and compatibility with various types of gas.

How to determine whether a lubricant is suitable for contact with gases?

When assessing the suitability of a lubricant for an application involving gas, several factors need to be taken into account. First, check whether the lubricant has been approved for specific use in contact with gas. Approvals such as DVGW, BAM and Air Liquid guarantee that the lubricant meets the required safety and performance standards. In addition, examine the lubricant’s properties, such as its operating temperature range, material compatibility and resistance to environmental conditions, to ensure that it is suitable for your specific application.

Approvals for lubrication in contact with gases

DVGW Approval:

DVGW-approved lubricants are certified for use in gas systems complying with German standards, guaranteeing proven performance under demanding conditions.

BAM Approval:

BAM-approved lubricants are approved for use in environments involving hazardous substances such as flammable gases or aggressive chemicals. VOLTALEF® HUILE 1A, VOLTALEF® HUILE 3A and VOLTALEF® HUILE 10A oils, as well as VOLTALEF® GRAISSE 90 grease, meet these stringent standards.

Air Liquid Approval:

These lubricants are designed to offer reliable performance and maximum safety in environments containing gas. VOLTALEF® GRAISSE 90 is recommended for lubrication to Air Liquid standards.

Applications in various industrial sectors

Lubricants suitable for contact with gas are used in a variety of industrial applications, including aerospace, automotive (especially hydrogen-powered vehicles), military, medical, extreme sports (such as diving) and navy (especially submarines).

Benefits and applications of VOLTALEF® lubricants approved by BAM and Air Liquide:

Chlorotrifluoroethylene polymer or PCTFE is one of the oldest fluoropolymers manufactured industrially, and VOLTALEF® uses it as the basis for the design of its lubricants.

Key points of VOLTALEF® lubricants:

- Thermal stability up to +250°C

- Excellent chemical resistance properties

- Non-flammability

- Low thermal conductivity

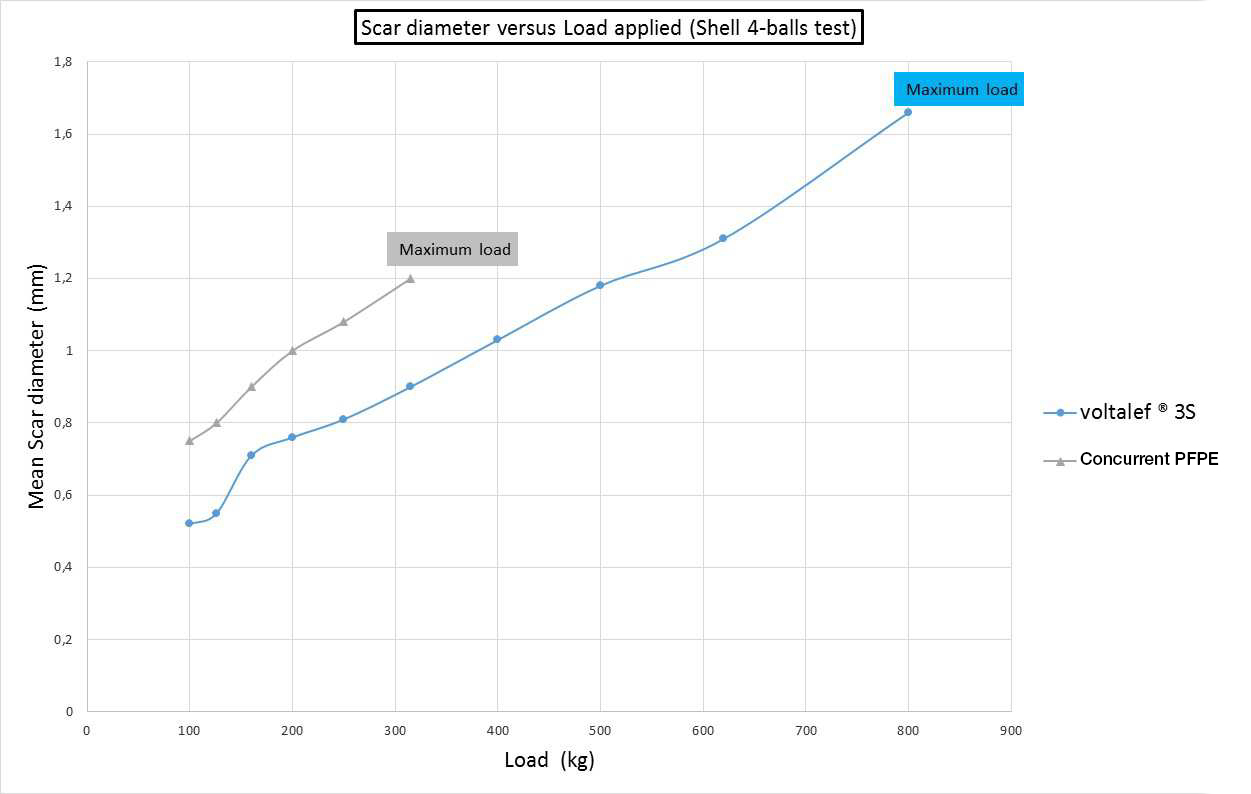

- Excellent high-load characteristics, can be used as additives in high-pressure oils

- Density around 2

Samaro recommends the following BAM and/or Air Liquide-approved VOLTALEF® PCTFE products:

- VOLTALEF® OIL 1A: non-flammable PCTFE oil (even under high oxygen concentration), insensitive to water and humidity, additive anti-corrosion and with very high chemical inertia. Temperature range: below -55°C to 141°C

Aggressive environment applications: compressor lubricants, hydraulic fluids, pump fluids, shock absorber fluids, heat exchanger fluids

BAM approved - VOLTALEF® OIL 3A: PCTFE oil, non-flammable (even under high oxygen concentration), insensitive to water and humidity, additive anti-corrosion and with very high chemical inertia. Temperature range from -45°C to 256°C

Application in aggressive environments

BAM approved - VOLTALEF® OIL 10A: PCTFE oil, non-flammable (even under high oxygen concentration), insensitive to water and humidity, additive anti-corrosion and with very high chemical inertia. Temperature range 0°C to 323°C

Application in aggressive environments

BAM approved - VOLTALEF® GREASE 90: high-temperature, non-flammable PCTFE grease. Used in contact with specific gases such as oxygen. Temperature range from 0 to 170°C

For valves and fittings used with chemicals, valves and fittings on nuclear sites.

BAM and Air Liquide approved.

VOLTALEF® lubricants are used for :

- Lubricants for compressors operating with oxygen

- Hydraulic fluids

- Pump fluids

- Shock absorber fluids

- Heat exchanger fluids

- Lubricants for valves subject to chemical attack

To sum up, choosing the right lubricant for a gas application is crucial to ensuring reliable equipment and safe industrial operations. By taking into account the appropriate approvals, lubricant characteristics and specific application requirements, you can ensure effective lubrication and optimum performance in gas environments.