DuPont™ MOLYKOTE® HP-300: A Cutting-Edge Solution for Hydrogen Purity

As hydrogen becomes a cornerstone of the transition to cleaner energy, ensuring its purity is crucial. Even trace levels of contaminants can compromise the efficiency and longevity of hydrogen-based technologies such as fuel cells. DuPont’s MOLYKOTE® HP-300 grease has been specifically designed to meet these challenges, offering exceptional performance in demanding applications.

Rigorous Testing and Compliance with Strict Standards

MOLYKOTE® HP-300 has undergone extensive evaluation in collaboration with HyCentA Research GmbH, a leading research institution specializing in hydrogen technologies. These tests were conducted in accordance with ISO 14687:2019, the international standard governing hydrogen purity.

The grease was exposed to high-pressure hydrogen (700 bar) for several weeks and subjected to detailed analysis for gaseous and particulate contamination. The results confirmed that MOLYKOTE® HP-300 does not introduce significant impurities, making it an ideal lubricant for critical hydrogen applications, including fuel cell stacks and storage systems.

Key Applications in the Hydrogen Industry

MOLYKOTE® HP-300 is suited for a variety of applications in the hydrogen sector, helping to improve reliability and reduce contamination risks. Here are some key use cases:

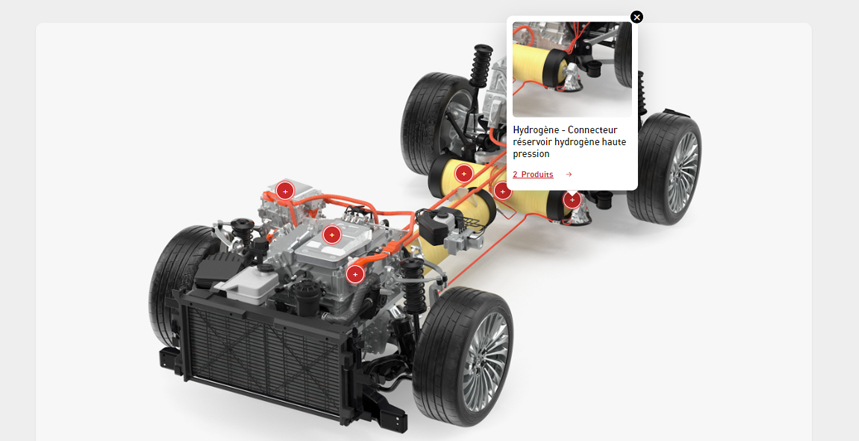

- Sealing Systems and Threaded Connections: Hydrogen transport and storage systems require leak-proof seals. MOLYKOTE® HP-300 ensures the integrity of these components while minimizing contamination risks.

- Fuel Cells: The grease helps maintain hydrogen purity, which is essential for optimal fuel cell performance and longevity.

- Hydrogen Refueling Stations: With its ability to perform in extreme temperatures (-40°C), MOLYKOTE® HP-300 ensures reliable lubrication in hydrogen fueling infrastructure.

Technical Properties and Key Benefits

MOLYKOTE® HP-300 stands out due to its advanced properties, which make it a superior choice for hydrogen-related applications:

- Exceptional Purity: Helps maintain hydrogen integrity by preventing contamination.

- High Chemical Resistance: Withstands exposure to hydrogen and a wide range of chemicals.

- Low-Temperature Performance: Functions effectively in conditions as low as -40°C, making it ideal for extreme environments.

- Broad Compatibility: Suitable for use with various materials, including elastomers and plastics.

- Prevention of Hydrogen Embrittlement: Protects sensitive components from degradation caused by hydrogen exposure.

Conclusion

MOLYKOTE® HP-300 grease is a vital solution for industries utilizing hydrogen, providing outstanding purity, durability, and compatibility with critical systems. By ensuring the integrity of hydrogen applications, this lubricant supports the advancement of cleaner energy technologies.

For professionals seeking a reliable and technically advanced solution, MOLYKOTE® HP-300 represents a breakthrough in hydrogen system performance. The certification confirming its compliance with strict purity standards is now available for download, reinforcing its position as a leader in hydrogen-compatible lubricants.