Customer experience at the heart of manufacturing: the case of Select Paddles’s X.GORM paddle

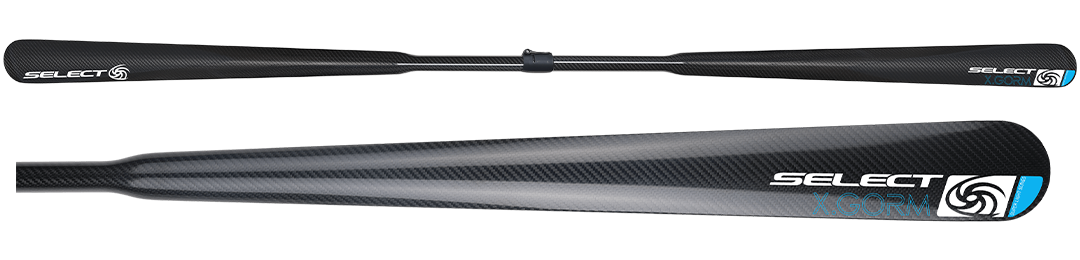

Customer experience has become a central element in the manufacturing process, where every technical and commercial decision is designed to meet the specific expectations of end-users. Stéphane Gourrichon, head of Select Paddles, shows us how the combination of traditional know-how and the technical expertise of the materials distributed by Samaro has led to the development of an exceptional product: the X.GORM paddle, a “Greenland style” carbon paddle.

A fruitful collaboration between Select Paddles and Samaro

At Select Paddles, every product is designed with attention to detail and performance. By choosing to work with Samaro and its partners (Airtech, Gurit, Huntsman, and Araldite®), Stéphane Gourrichon was able to benefit from support throughout the manufacturing process, from material selection to final assembly.

The result? A traditional dismountable carbon paddle, the X.GORM, distinguished by its precision and comfort. Featuring cutting-edge composite technology, this paddle is adjustable in length (from 215 to 230 cm) and offers silent, fluid navigation thanks to its thin 3mm edges. These technical features are directly linked to the use of top-of-the-range materials supplied by Samaro.

Materials at the cutting edge of innovation

Vacuum bagging films: Airtech DAHLAR® BAG 125 SHT and 460 LFT-GUSSET

Vacuum bagging films are essential in the composites manufacturing process. To guarantee impeccable quality and finish, Stéphane Gourrichon used Airtech DAHLAR® BAG 125 SHT and DAHLAR® BAG 460 LFT-GUSSET high-performance vacuum bagging films.

- DAHLAR® BAG 125 SHT: This high-performance vacuum film, 50 microns thick, was used for the vacuum fabrication of composite paddle elements. Its puncture resistance and elasticity enable it to adapt to curing cycles of up to 125°C, guaranteeing uniform, efficient vacuum bagging.

- DAHLAR® BAG 460 LFT-GUSSET: This film is particularly useful in autoclave molding, where high temperatures (up to 238°C) are required. It has made it possible to work on complex shapes, thanks to its gusset which facilitates placement.

Samaro support: more than a distributor, a technical partner

Samaro’ s technical support played a key role in the success of the X.GORM paddle. In addition to supplying cutting-edge materials, Samaro offered invaluable technical advice throughout the manufacturing process, including the choice of resins, adhesives and vacuum bagging processes.

Conclusion

As a distributor of leading brands such as Airtech, Gurit, Huntsman, and Araldite, Samaro provided Select Paddles with cutting-edge technical expertise and access to high-quality products. This partnership was essential in the development of the X.GORM paddle, an innovative, high-performance product that meets the demands of kayak users. Thanks to Samaro’s support, Select Paddle was able to bring an ambitious project to fruition by integrating the best composite materials on the market.