Bonding metal to metal: The advantages and techniques, with Born2Bond™ Structural

To ensure optimal metal-to-metal bonding, it is essential to carefully prepare the surface of the materials to be bonded before any application.

With this in mind, Samaro and its partner Socomore recommend the use of Diestone DLS. This cleaning and degreasing agent, free from chlorinated hydrocarbons, evaporates quickly, providing optimum surface preparation for effective metal-to-metal bonding.

Metal-to-metal bonding is an essential practice in many industrial sectors, providing robust and durable fastening solutions. Among the best performing adhesives for this application, Born2Bond™ Structural stands out for its two-component Cyanoacrylate / Acrylate hybrid properties, offering exceptional adhesion and long-term strength. In this article, we’ll explore the benefits and techniques of metal-to-metal bonding, highlighting Born2Bond™ Structural as the solution of choice for professionals.

Benefits of metal-to-metal bonding

- Exceptional bond strength: Born2Bond™ Structural offers impressive bond strength, with resistance up to 14 MPa on sandblasted mild steel. This superior adhesion ensures a strong and durable bond, even in demanding environments.

- Resistance to mechanical stress: Unlike traditional fastening methods such as welding or riveting, metal-to-metal bonding distributes mechanical stress evenly across the bonded surface, reducing stress points and improving the durability of the joint.

- Waterproofing and corrosion protection: By forming a watertight bond between metal surfaces, Born2Bond™ Structural provides effective protection against moisture, chemicals and corrosion, extending the life of assembled parts.

- Design flexibility: metal-to-metal bonding allows parts with complex shapes and different materials to be attached, offering increased design flexibility over traditional fastening methods.

Metal-to-metal bonding techniques with Born2Bond™ Structural

- Surface preparation: Prior to bonding, it is essential to carefully prepare metal surfaces by degreasing and sandblasting to remove all traces of contamination and ensure optimum adhesion of the adhesive.

- Adhesive mixing and application: Born2Bond™ Structural is a two-component adhesive, requiring accurate mixing of both components prior to application. Once mixed, the adhesive is applied evenly to the prepared surfaces using a spatula or application syringe.

- Pressure and curing: Once the adhesive has been applied, the assembled parts are pressed firmly together to ensure close contact between the bonded surfaces. The curing of the adhesive can be accelerated using heat or catalysts, depending on the specific requirements of the application.

- Curing time and post-treatment: The curing time of Born2Bond™ Structural varies depending on the ambient conditions and the amount of adhesive applied. After full cure, assembled parts can be subjected to additional treatments such as grinding, polishing or coating to meet finish and performance requirements.

The features of Born2Bond™ Structural:

Composition: Two-component Cyanoacrylate / Acrylate hybrid adhesive.

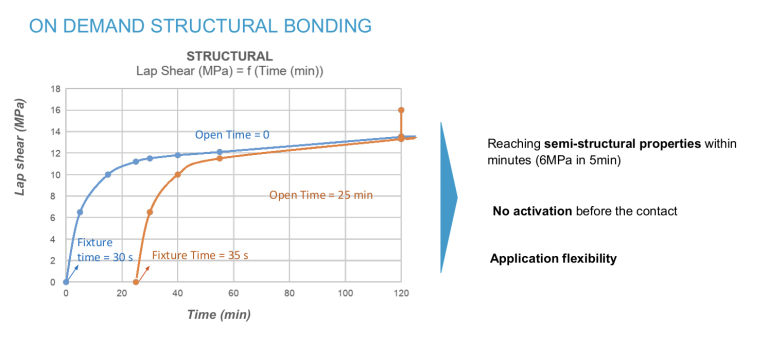

Pot-life: 25 minutes, providing an optimum working window.

Maximum gap: 5 mm, allowing adaptation in a variety of assembly situations.

Temperature range: Works effectively in conditions from -40°C to 120°C, ensuring stable performance in a variety of environments.

Fast setting: Cures at room temperature, speeding up assembly processes.

Impact resistance: Offers protection against external mechanical forces, ensuring joint durability.

Temperature and moisture resistance: Maintains its properties in extreme conditions, ensuring long-term reliability.

Excellent adhesion: Bonds effectively to a variety of substrates, ensuring a strong connection in a range of applications, including aluminium, steel, plastics and elastomers, as well as porous substrates such as wood, chipboard and leather (except polyolefins).

Gel consistency: Facilitates precise application, minimising spillage and mess.

Clear when cured: Ensures a clean appearance, ideal for applications where visibility is important such as glass.

Mixing ratio: 4:1, ensuring simple and accurate preparation.

Handling time: 5 minutes, allowing careful adjustment of parts before full cure.

Adhesive strength: 6 MPa after just 5 minutes from application, ensuring a strong bond from the outset.

Assembly process: The joint components should be assembled and fixed in position as soon as the adhesive is applied.

Repositioning possible: Bonded substrates can be repositioned for a short time after curing has begun, providing flexibility in the assembly process.

Industrial applications of metal-to-metal bonding

Metal-to-metal bonding has a wide range of applications in many industrial sectors, due to its many advantages over traditional methods such as welding, screwing or riveting. Here are just a few examples of industrial applications where metal-to-metal bonding is commonly used:

Automotive industry :

- Bonding body parts for a better finish and reduced weight

- Assembly of interior components such as dashboards and door panels

- Fixing trim and accessories

Aerospace :

- Bonding fuselage and wing panels for a lighter, stronger structure

- Joining critical structural components such as spars and ribs

- Repair of damaged parts

Construction :

- Bonding steel beams and columns for lighter, more rigid structures

- Fixing metal cladding to façades and roofs

- Assembling prefabricated modules

Electronics :

- Bonding electronic components to printed circuits

- Encapsulating components to protect them from the environment

- Fixing heat sinks to cool electronic components

Machinery and equipment:

- Bonding machine parts to improve resistance to vibration and noise

- Repairing broken or worn parts

- Assembling complex components

Other applications :

- Bonding train and tram rails

- Manufacture of medical and surgical equipment

- Repairing jewellery and works of art

To conclude, metal-to-metal bonding with Born2Bond™ Structural offers an effective and versatile solution for industrial fastening applications. With its exceptional bond strength, resistance to mechanical stress and ease of use, this two-component Cyanoacrylate / Acrylate hybrid adhesive meets the most stringent requirements of professionals. By adopting this innovative fastening method, companies can improve the quality, durability and profitability of their products, while opening up new possibilities for design and innovation.

Need equipment?

Samaro has you covered!

Here is a selection of equipment to meet the needs of the products mentioned in this article:

Bicomponent manual gun |

||||||

Designation |

Capacity |

Maximum thrust |

Trigger Ratio |

Product viscosity |

Weight |

|

|

MR 50 Delivered with accessory kit to adapt to any type of cartridge 2k 50 ml |

Cartridge 50 ml |

2,5 kN | 13:1 | Low to medium | NC |