Araldite® 2023 : High performance methacrylate structural adhesive for multi-material assembly

Araldite® 2023 is a two-component, room-temperature curing methacrylate adhesive specifically designed for bonding a wide range of substrates: composites, metals, and engineering plastics. Available in three versions — with open times of 10, 30, or 60 minutes — it adapts to various industrial production rates while ensuring high mechanical, chemical, and environmental performance.

Why Use a Methacrylate Adhesive for Multi-Material Assemblies?

Modern industries increasingly design complex structures combining different materials such as aluminum, steel, thermoset composites, technical plastics, and fiberglass. These hybrid assemblies demand high compatibility, flexibility, and long-term durability.

Araldite® 2023 was developed to meet these challenges by providing strong, long-lasting bonds between dissimilar substrates while simplifying industrial application through adjustable open times.

Technical Features of Araldite® 2023

Technical Data Summary

| Property | Value |

|---|---|

| Product type | Two-component methacrylate adhesive |

| Mixing ratio | 10:1 |

| Color | Light grey (UV stable) |

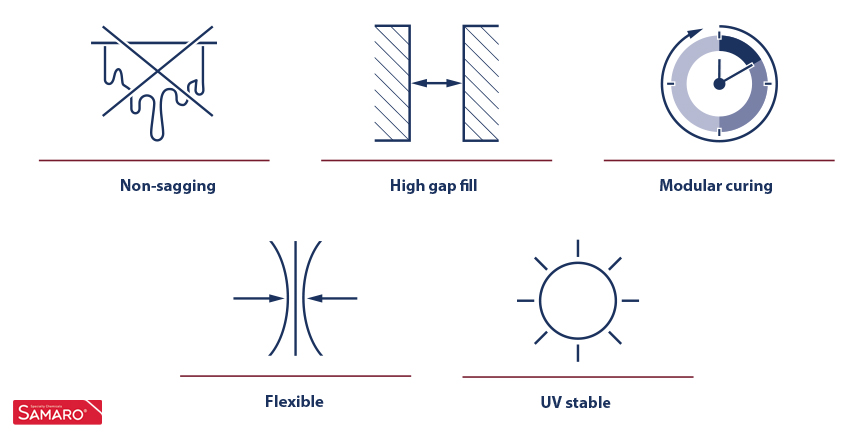

| Viscosity | Thixotropic |

| Operating temperature | -40 °C to +120 °C |

| Young’s modulus | 700 MPa |

| Elongation at break | > 100% |

| Shear strength | Up to 16 MPa |

| Gap filling capacity | Up to 30 mm |

| Curing | At room temperature |

These properties make Araldite® 2023 a reliable solution for mechanically stressed or environmentally exposed structural bonds.

Three Open Times to Match Your Process

| Version | Open Time | Recommended Application |

|---|---|---|

| Araldite® 2023-10 | 10 minutes | Fast assembly, industrial production lines |

| Araldite® 2023-30 | 30 minutes | Adjusted positioning, mid-sized parts |

| Araldite® 2023-60 | 60 minutes | Large parts, complex geometries |

🔍 Open time refers to how long the adhesive remains workable before curing begins — essential for optimizing production speed and ensuring assembly precision.

Key Technical Advantages for Multi-Substrate Bonding

✔ Simplified Surface Preparation

Araldite® 2023 bonds well to many materials with minimal surface preparation — often just cleaning, without sanding or priming — reducing process steps while maintaining long-term performance.

✔ Multi-Material Compatibility

Suitable for bonding composites (SMC/BMC), metals (steel, aluminum), and plastics (ABS, PC, PMMA), even with minimal surface prep.

✔ Stress Resistance

Excellent mechanical performance under shock, vibration, and dynamic loads — even between materials with differing thermal expansion rates.

✔ Vertical Surface Application

Its thixotropic, non-sagging formulation allows clean and precise application on walls, ceilings, or complex geometries.

✔ Aesthetic & Durability

The light grey, UV-stable adhesive ensures a consistent visual appearance over time with no yellowing or degradation outdoors.

Typical Applications by Sector

Transportation & Rail

- Bonding of metal and composite components in vehicle bodies, floors, and partitions.

- Certified to EN 45545-2 for fire and smoke safety in railway applications.

- Ideal for hybrid steel/composite structures in heavy vehicles and trains.

Marine Industry

- Used to bond composite hulls, aluminum panels, and modular interiors.

- Approved by Lloyd’s Register, suitable for marine environments exposed to moisture, salt, and structural loads.

Renewable Energy

- Fixing components in wind turbines and photovoltaic panels.

- Ideal for UV-exposed composite-to-plastic assemblies enduring outdoor conditions.

Choosing Between 2023-10, 2023-30, or 2023-60

| Criteria | 2023-10 | 2023-30 | 2023-60 |

|---|---|---|---|

| Available assembly time | Very short | Moderate | Long |

| Part size | Small to medium | Medium | Large / complex |

| Geometry complexity | Low | Medium | High |

| Substrate types | Plastics / metals | Composites / metals | Multi-material |

| Production constraints | Automated line | Manual station | Unit assembly |

The right version depends on assembly complexity, material types, and required working time.

❓ FAQ – Araldite® 2023

🔹What’s the difference between Araldite® 2023-10, 2023-30, and 2023-60?

Mainly the open time (the period before curing starts):

- 2023-10: 10 minutes – fast production cycles.

- 2023-30: 30 minutes – standard bonding with adjustment time.

- 2023-60: 60 minutes – complex or large assemblies requiring extended positioning.

🔹Is it compatible with metals, plastics, and composites?

Yes. Araldite® 2023 is specially formulated for multi-material bonding. It bonds aluminum, stainless steel, SMC, BMC, PC, ABS, PMMA, etc., effectively.

🔹Can it be applied to vertical surfaces?

Yes. Its thixotropic (non-sagging) formula allows application on vertical walls, ceilings, or slanted surfaces.

🔹Is it certified for rail and marine applications?

Yes. It is:

- Certified EN 45545-2 for railway (fire/smoke)

- Approved by Lloyd’s Register for marine use

🔹Can it be used outdoors?

Yes. It resists UV, moisture, and freeze-thaw cycles while maintaining its mechanical and visual properties.

🔹What equipment is needed for application?

Araldite® 2023 is easily applied with the VBM400XMR Manual Gun (10:1 ratio) and a static mixer. No thermal curing system or perfectly prepped surface is required.

Conclusion

Araldite® 2023 is a structural methacrylate adhesive designed for durable bonding of dissimilar materials: composites, metals, and technical plastics.

Its non-sagging formulation, high flexibility (elongation > 100%), and ability to fill large gaps (up to 30 mm) make it an ideal solution for complex industrial applications.

Available in three versions — 2023-10, 2023-30, and 2023-60 — it fits all kinds of manufacturing processes, from fast-paced serial assembly to large-scale manual builds.

Certified EN 45545-2 for railway and Lloyd’s Register for marine sectors, it ensures reliable performance in even the most demanding environments.