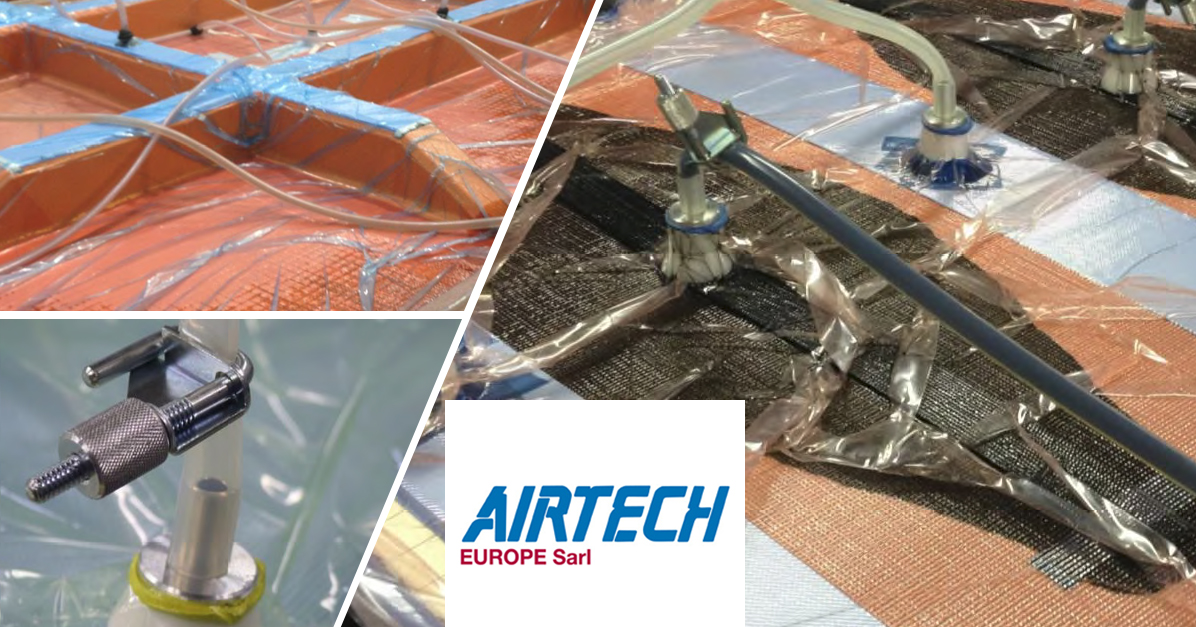

Airtech supports you for high temperature infusion (from 120°C).

Airtech, world leader in vacuum accessories and peripherals for high temperature infusion preparation

Through its new infusion brochure, Airtech and Samaro offer you a selection of products for high temperature room infusion (>120°C up to 180°C).

Airtech has selected from its wide range, a selection of :

- Vacuum bag,

- Micro-perforated release film,

- Adhesive tape,

- Release adhesive films,

- Tear-off fabrics,

- Rubber,

the products for feeding and draining the resin as well as all the necessary tools for the preparation of the infusion.

Products for high-temperature infusion :

| References | Maximum use temperature | Colour | Features |

|---|---|---|---|

Vacuum bag |

|||

| Airtech Wrightlon 5200 | 260°C | Blue / Red / Clear/ Yellow | Elongation : 350% / Tensile strength : 48 Mpa |

Double-sided tape |

|||

| Airtech AIRHOLD 1 CBS | 204°C | Clear | Film support : polyester / adhesive : Acrylic |

Drainer |

|||

| Airtech Resinflow 90HT | 177°C | Clear | Weight: 160 g/m² / Grid type : Extruded Nylon |

| Airtech KNITFLOW 105 HT | 200°C | Clear | Weight: 105 g/m² / Grid type : Knitted Nylon |

Infusion accessories |

|||

| Tuyau Nylon | 180°C | White | Type : Nylon |

| Tuyau Nylon Spiralé | 180°C | White | Type : Nylon |

| Sil-tub (tuyau silicone) | 230°C | Clear | Type : Silicone |

| Connecteur résine RIC HT | 180°C | Black | Type : Nylon / Pour couplage de tuyau spiralé |

| Connecteur vide RIC HT | 180°C | Black | Type : PTFE / Embase plate |

| RIA | 260°C | Metal | Type : Inox |

More informations :

Do you need information about Airtech ? Contact our technical department on +33 426 680 680 or fill in our contact form.

Download the Airtech brochure dedicated to composite market :

Airtech has also updated its brochures offering a suitable selection for :

Vacuum Bagging for General Composite Molding : The manufacture of composite parts under vacuum compaction Prepreg, wet process under vacuum, whatever the shape and temperature of the process: Vacuum bag, drainage felt, micro-perforated or non-perforated release films, tear-off fabrics, adhesive tape, release agents, rubber, vacuum hoses and vacuum pump or autoclave connection, vacuum valve and quick coupling, accessories for control (vacuum, temperature etc…), tools for processing (scissors, cutting support etc…). ), compression rubber (shaped, liquid or pasty).

Vacuum Bagging Materials for Glass Lamination : The manufacture of laminated glass: Vacuum bag, drainage felt, adhesive tape, gaskets, vacuum hoses and vacuum pump or autoclave connection, vacuum valve and quick coupling, accessories for the control (vacuum, temperature etc…), tools for the implementation (scissors, cutting support etc…).