DOWSIL™ EA-3838 Fast Adhesive

Growth in the global adhesives and sealants market

The size of the global adhesives and sealants market is estimated to reach USD 82.4 billion by 2025. This corresponds to a CAGR of 5.6% during the forecast period.

The strong demand for adhesives and sealants comes from various industries:

- Construction

- Assembly

- Automotive

- Household appliances

- Aviation

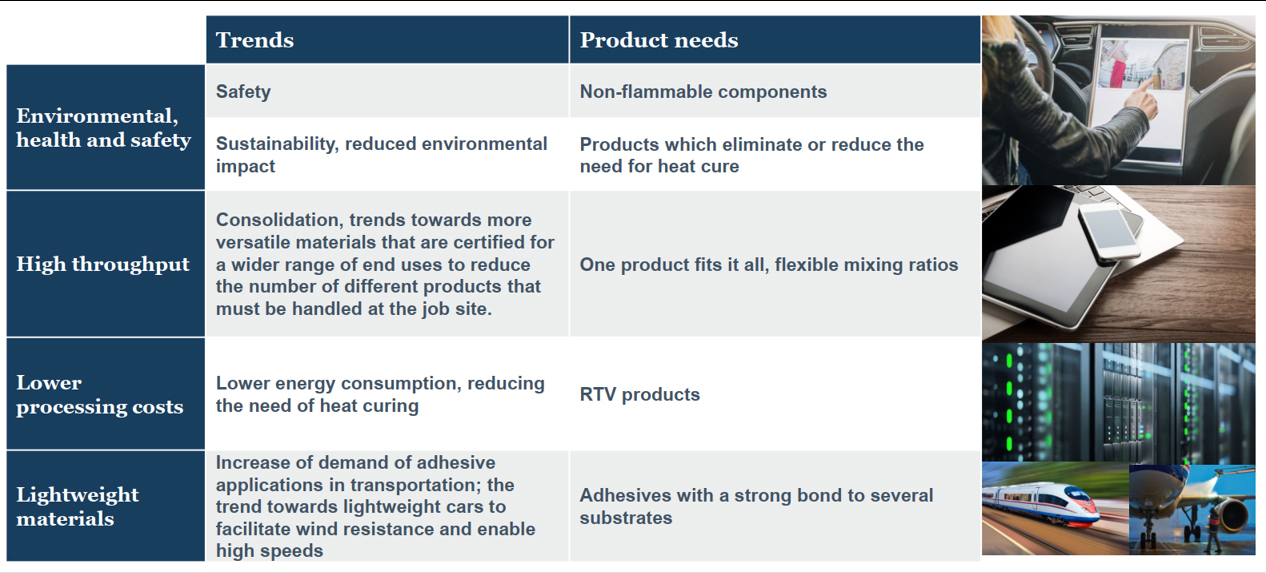

Key growth trends

Meeting needs: Improving profitability and reducing carbon footprint.

DOWSIL™ EA-3838 Fast Adhesive was developed for manufacturers of appliances, automotive electronics, lighting, aerospace and beyond, looking to improve profitability while reducing costs and their carbon footprint.

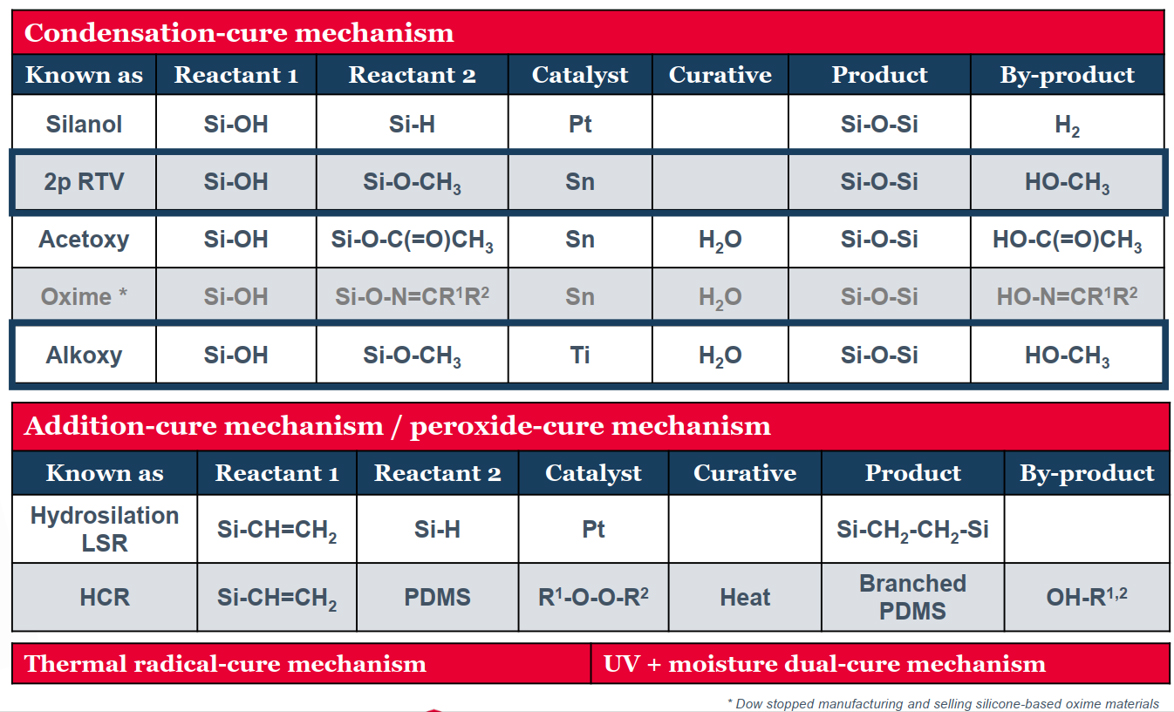

Silicone curing technologies

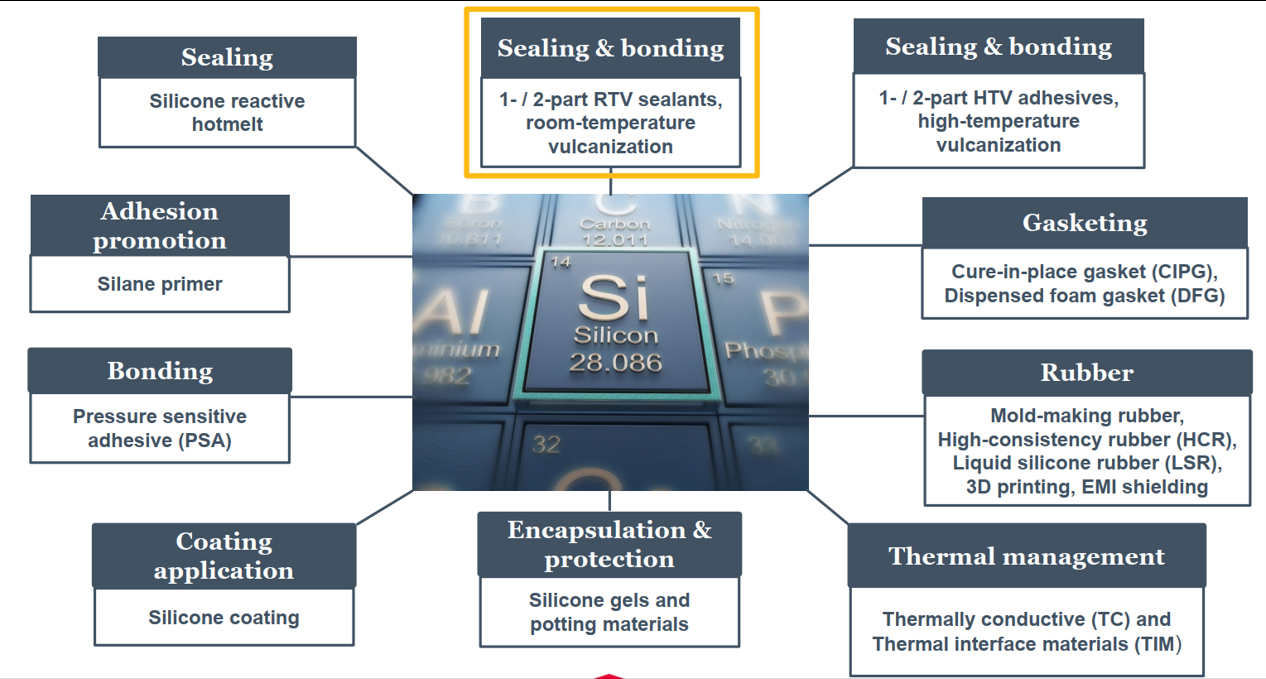

Silicone technologies

Seadling and bonding: Vulcanisation at room temperature

Packaging / Delivery / Storage

Typical storage conditions for one part RTV sealants: When stored at or below 30°C (86°F) in the original unopened containers, this product has a useful life of 12 months from the date of production.

Storage Conditions for SILASTIC™ Q3-3636, RTV Two-part Adhesive Catalysts: When stored at or below 25°C in the original unopened containers, SILASTIC™ Q3-3636 catalysts have a useful life of 5 months from the date of production.

Typical storage conditions for one part RTV sealants: When stored at or below 30°C (86°F) in the original unopened containers, this product has a useful life of 12 months from the date of production.

Storage Conditions for SILASTIC™ Q3-3636, RTV Two-Component Adhesive Catalysts: When stored at or below 25°C in the original unopened containers, SILASTIC™ Q3-3636 catalysts have a useful life of 5 months from the date of production.

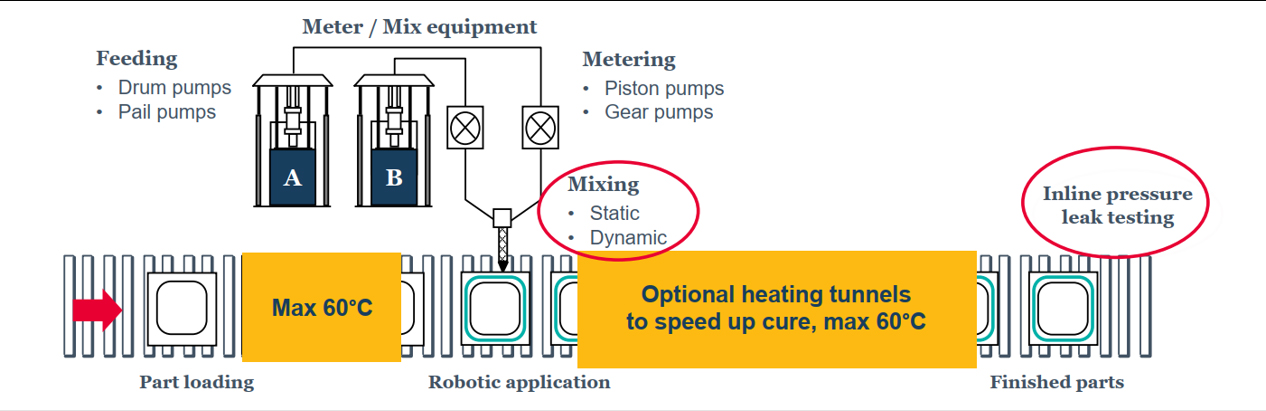

Dispensing / Application

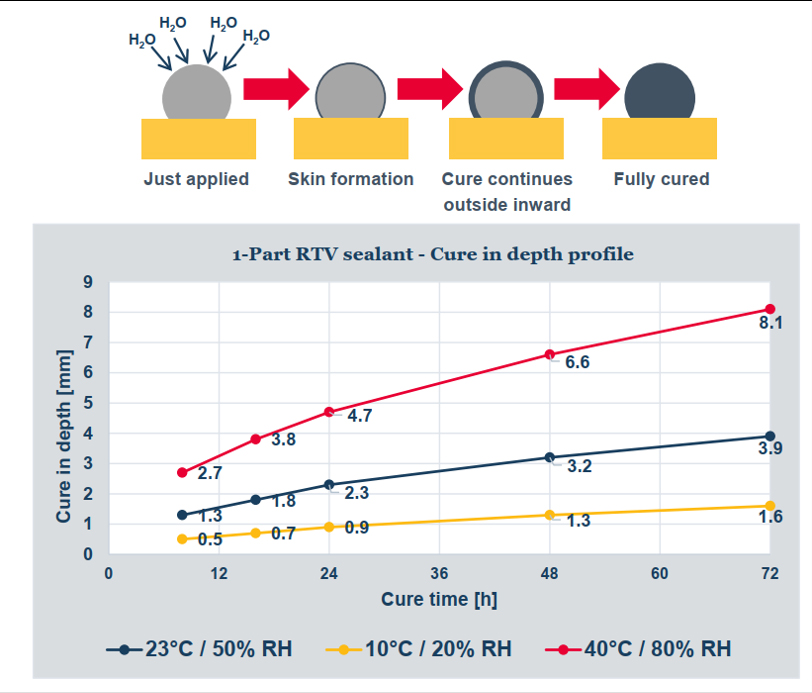

One part RTV equipment is less complex as it does not require mixing or heating tunnels. This is because short-term heat has no significant effect on the cure rate.

BUT a storage area is required for curing the finished parts. The time spent in the storage area depends on :

- temperature and humidity

- the design of the part

- the follow-up processes.

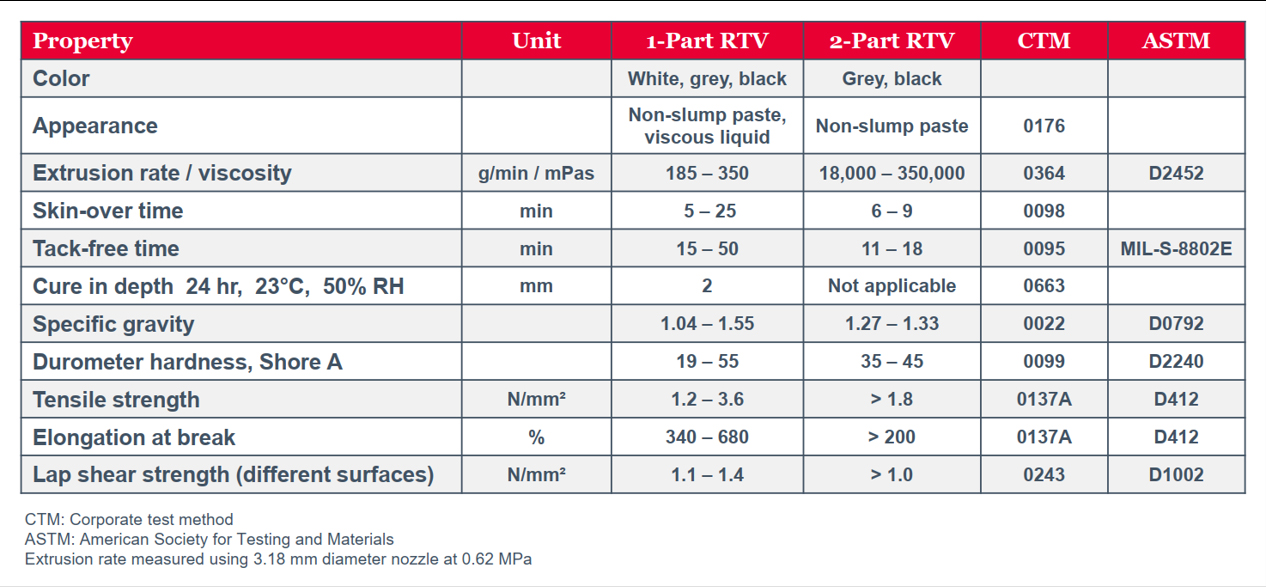

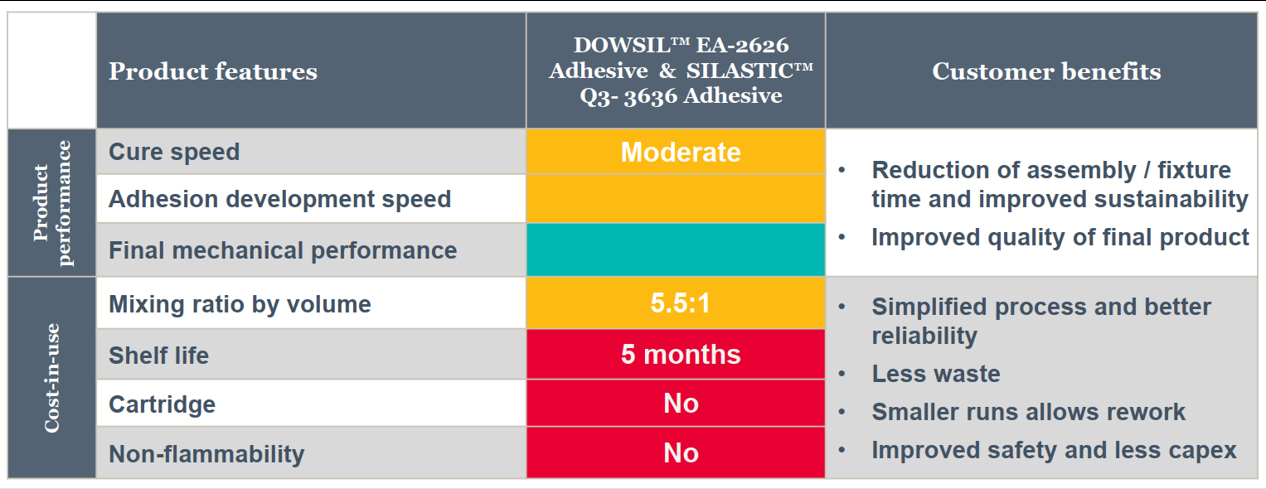

The mixing ratio of current RTV Two-part sealants is 100:14 by weight (100:17 by volume). Uneven mix ratio:

- Requires different pumps to be dosed correctly

- Requires precise control of the mix ratio

- Means that no commercial cartridge system is available.

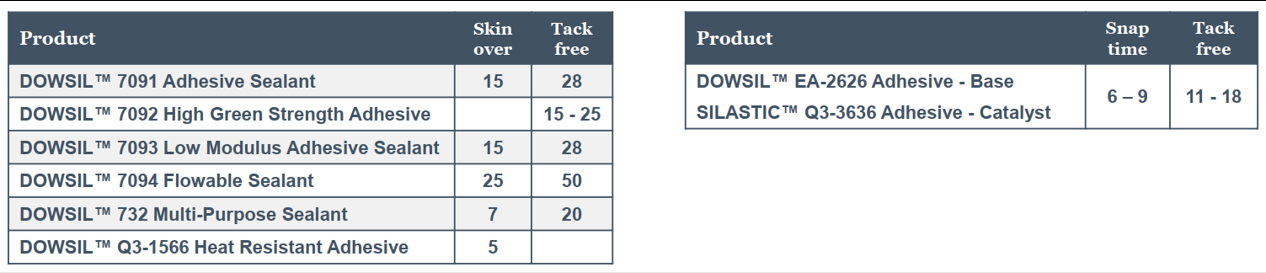

OpenTime / Tack-free Time

One-Part RTV

Curing rate – skin contact time / fingertip non-adhesion time

Summary: Cure time, a measure of cure rate, is defined as the time in minutes required for a curing material to form a non-sticky surface film.

Tow-Part RTV

Working time – snap technique

Summary: This technique measures the time taken for a room temperature vulcanising material to show the first sign of rubberisation after the material has been fully formulated and exposed to normal curing conditions.

Curing rate – recovery time / time without adhesion by contact with polyethylene

Summary : Cure time (a measure of cure rate) is defined as the time in minutes of cure required for a material to form a non-sticky surface film. This method uses contact with a polyethylene film to determine the non-stick characteristic and can give a positive or negative result if the recovery time is specified as a minimum.

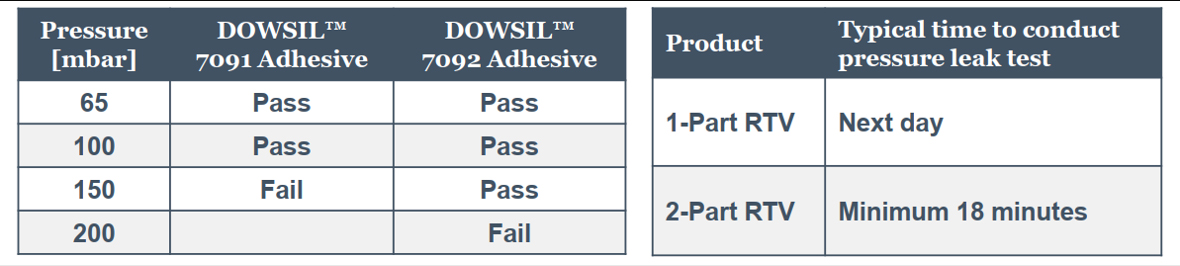

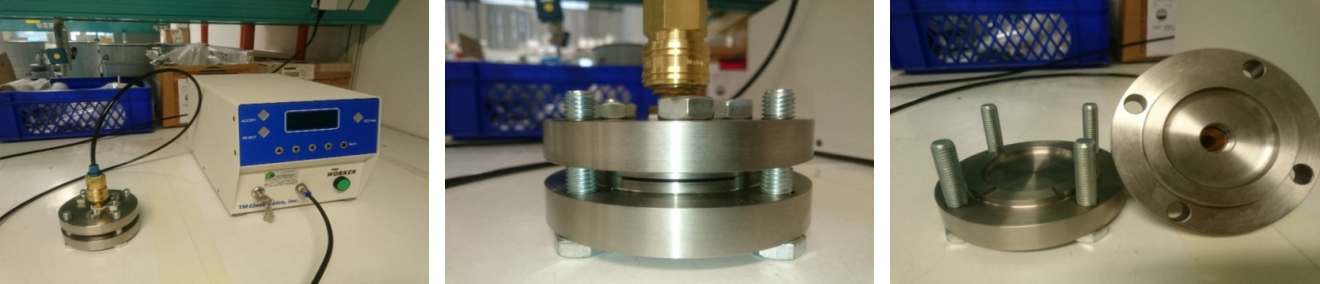

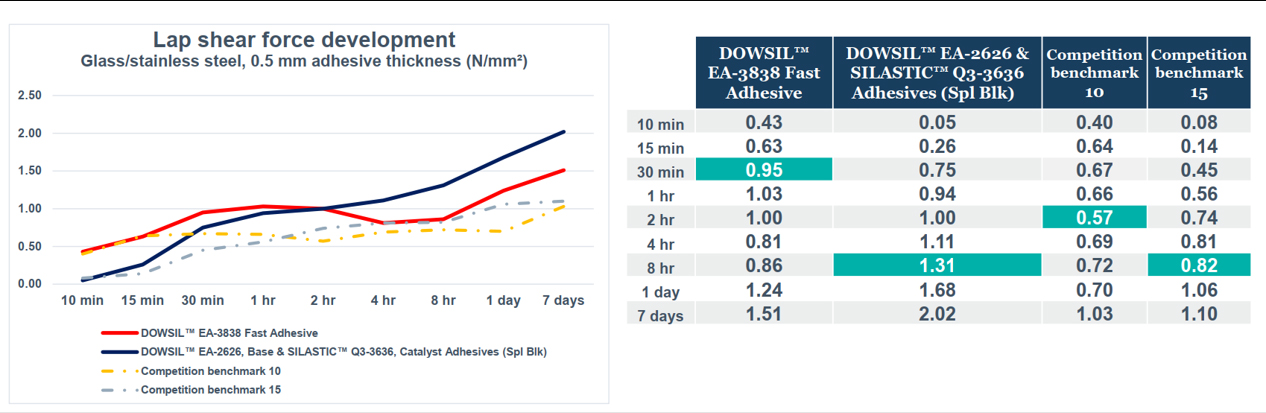

Continuous pressure leakage test (inline)

The inline pressure leakage test can be performed with the Time Worker from TM Electronics, Inc. in combination with a metal template conforming to ASTM F2523-13. The template has a gap of 1 mm high and 8 mm wide. A small bead of material was applied around the flange of the metal template. Immediately after the material was applied, the template was assembled and the test began.

- Dow Laboratory leakage test parameters : Load 6.5 kPa for 80s -► hold 6.5 kPa for 5s -► test.

- Test duration: hold 6.5 kPa for 120s

- Success criteria: Pressure decay max. 0.1 kPa

- The test parameters are application and customer specific.

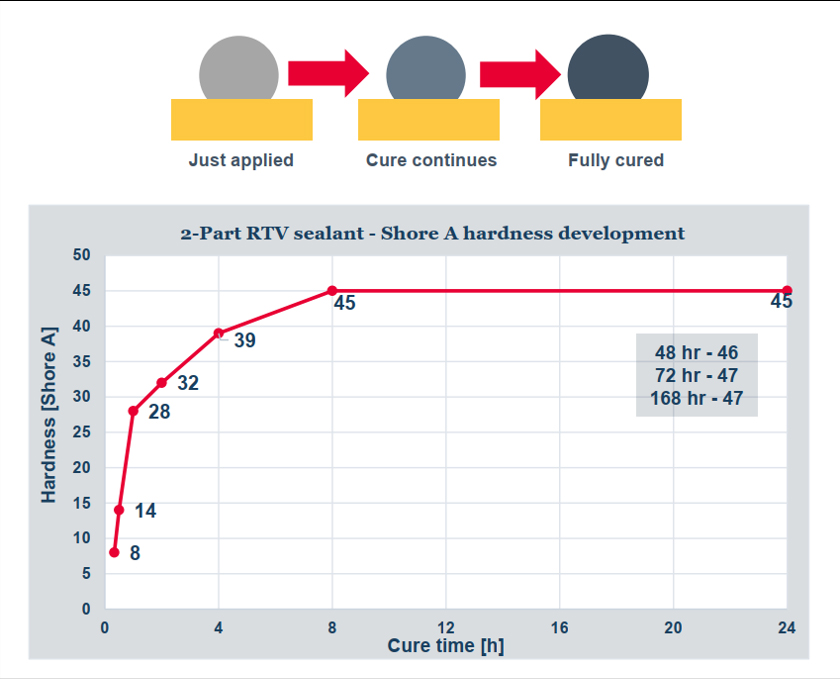

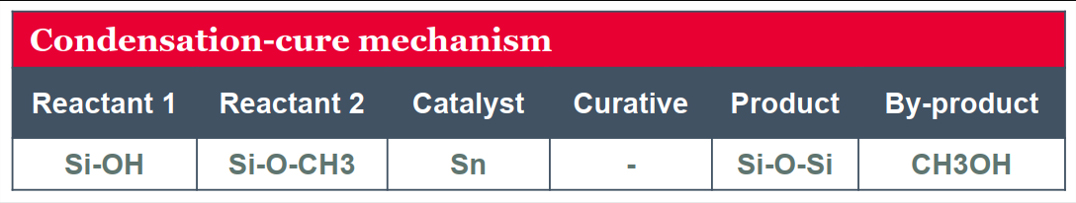

Type of curing

One-Part RTV :

Tow-Part RTV :

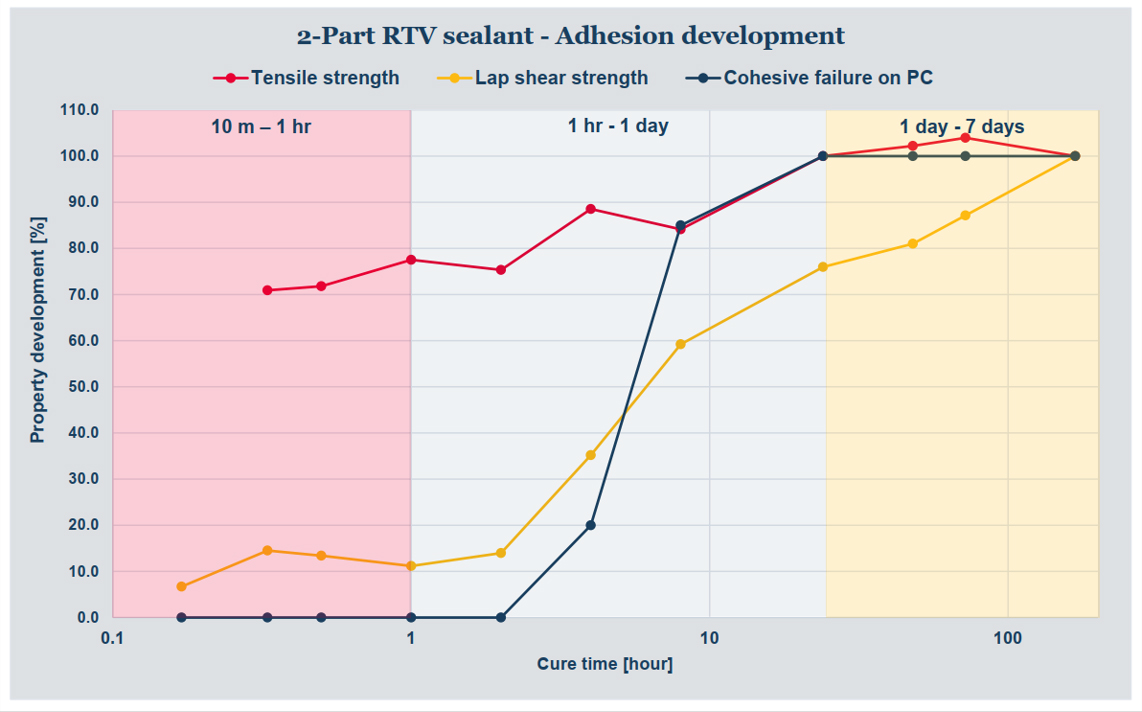

Adhesion development

Key features:

Specific features :

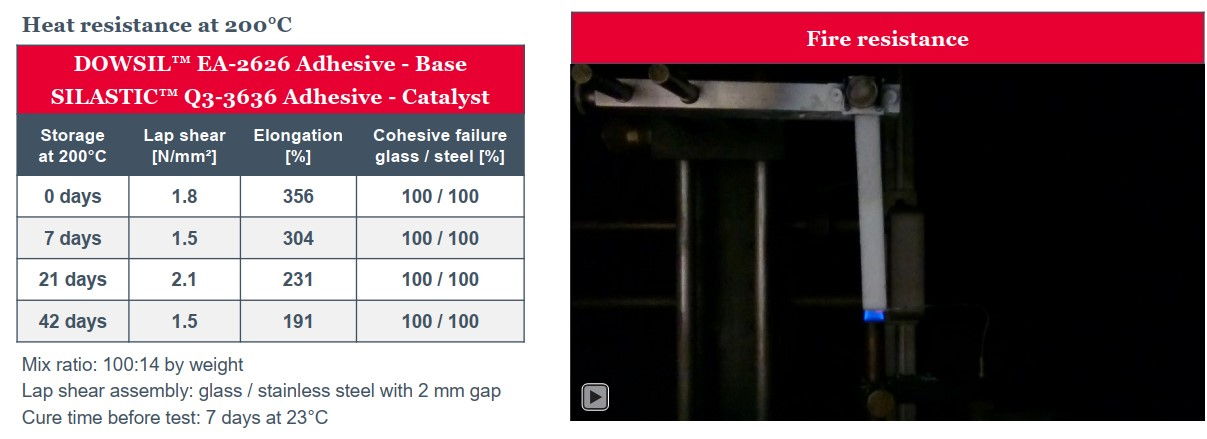

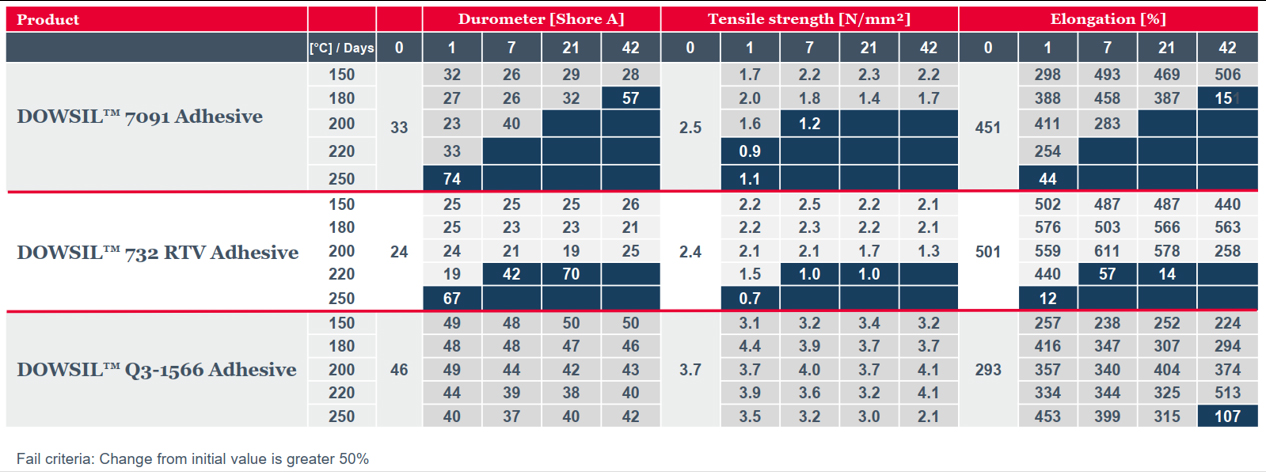

Heat resistance at 200ºC

Heat resistance by product

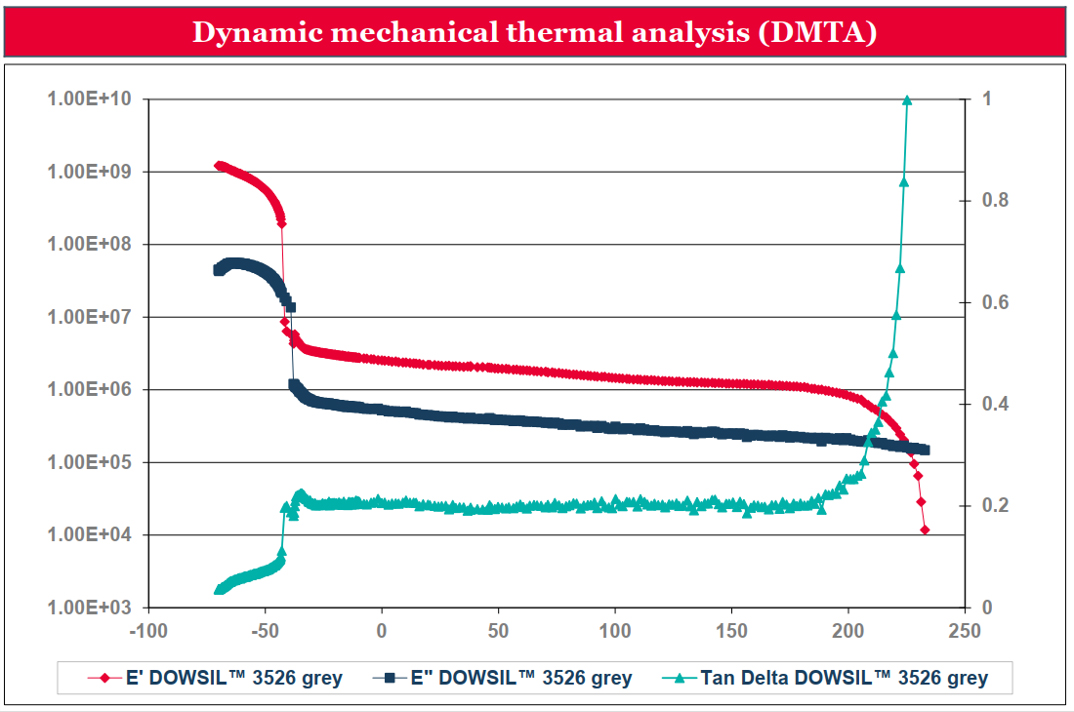

Dynamic Mechanical Thermal Analysis (DMTA)

Summary

Technical Introduction to DOWSIL™ EA-3838 Fast Adhesive

Product Information

- A two part, alkoxy RTV material that develops early adhesion without primer to various substrates, with a very fast cure rate.

- This adhesive consists of a black base and a white catalyst.

- It has a variable volumetric mixing ratio of 2:1 to 4:1, non-flammable components and a shelf life of 12 months for both components.

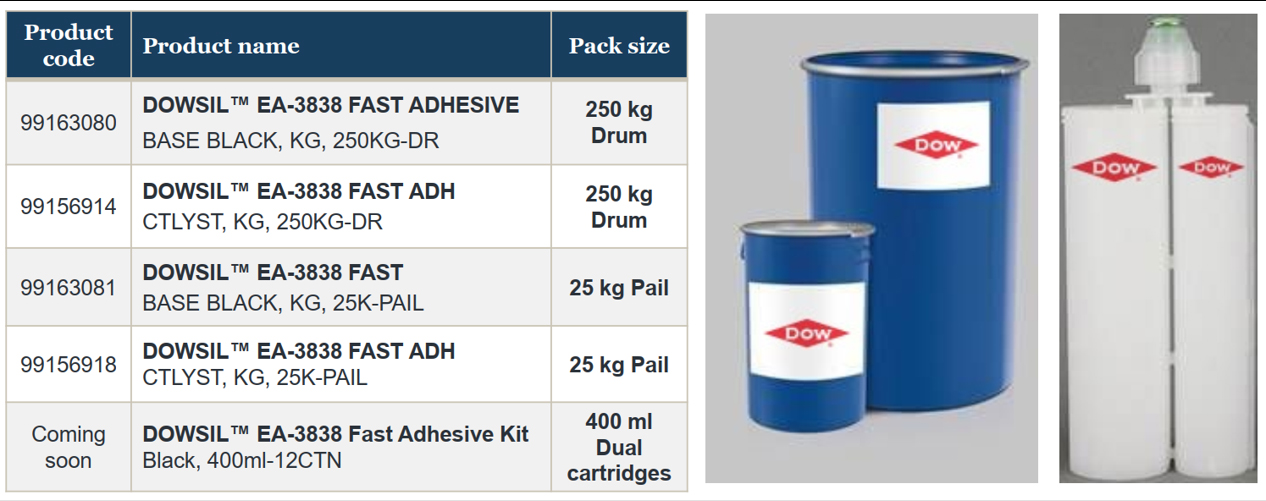

- It will be commercially available in pails, drums and two-cartridge kits.

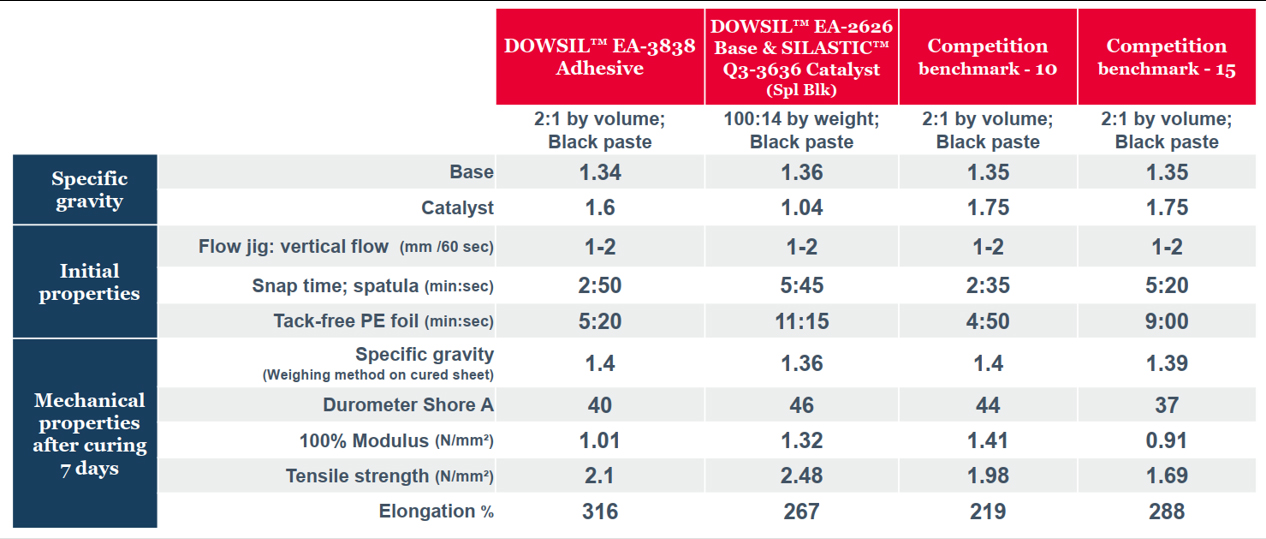

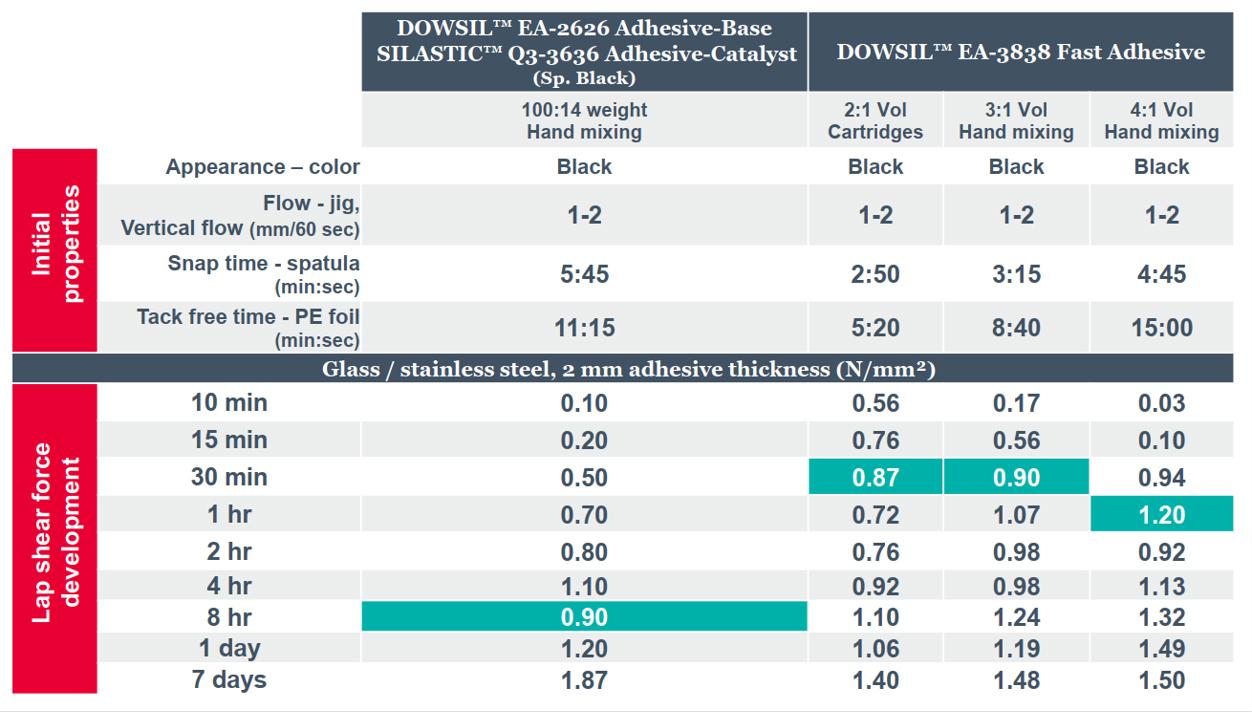

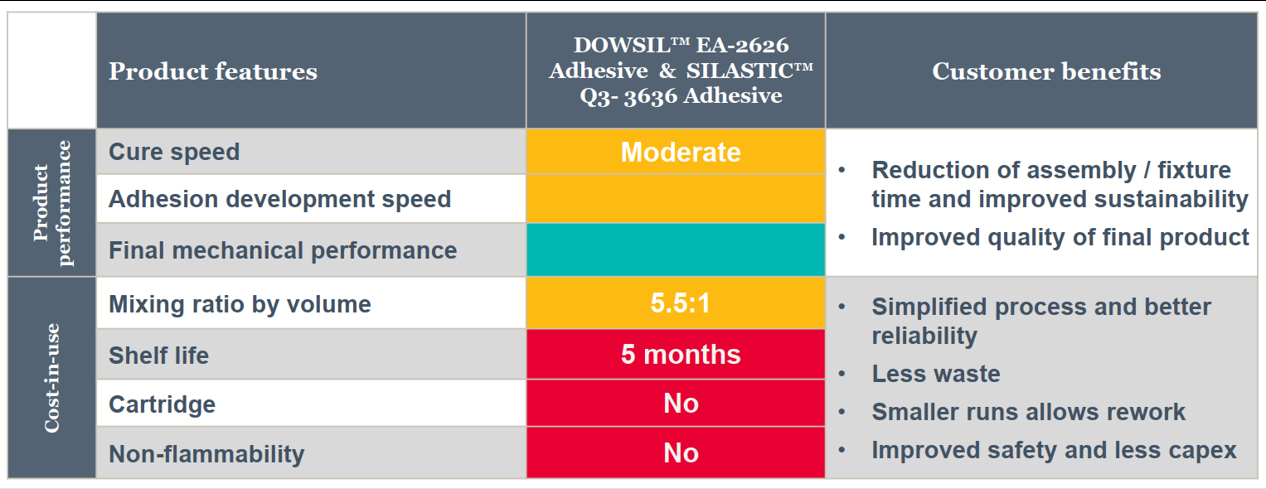

Mechanical properties and competition

Speed of curing and early adhesion development

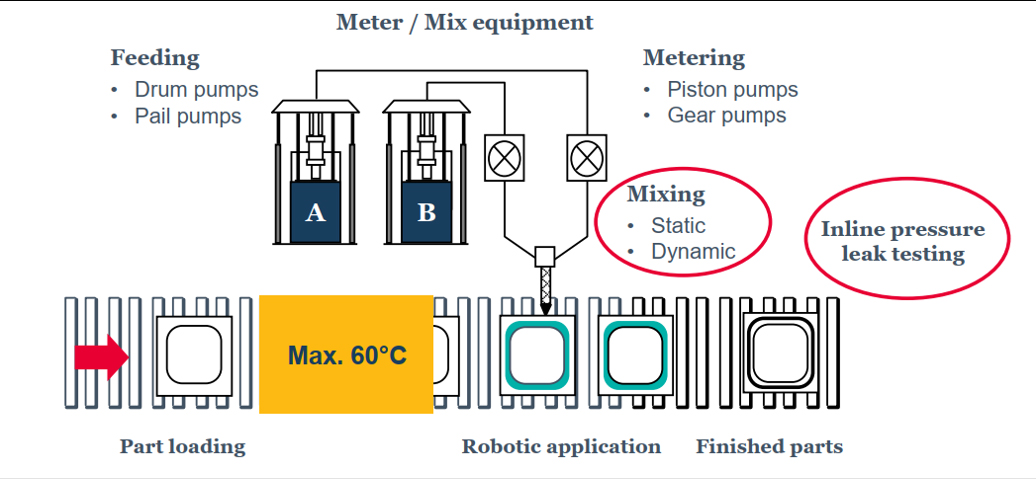

Distribution / Application; one-part and two-part RTV

- Eliminates the need for oven acceleration, but can be accelerated by heating tunnels – max 60°C

- Elimination of heat reduces energy consumption and improves durability.

- Faster curing allows for earlier in-line pressure testing, significantly reducing cycle time.

- Variable mixing ratio allows a wide range of open times and cure speeds to be met.

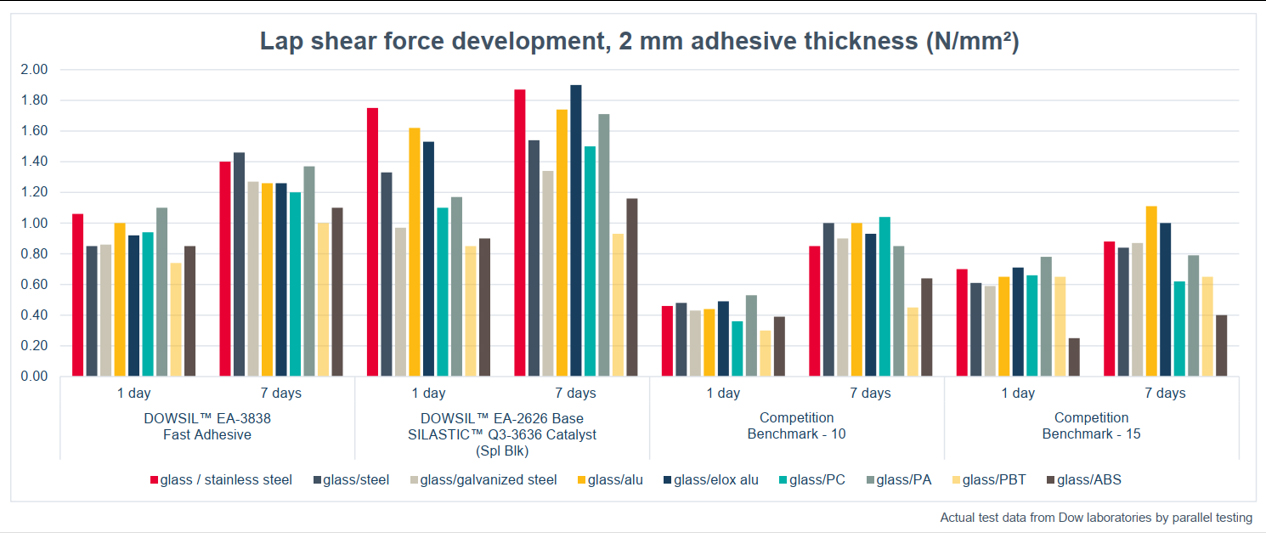

Adhesion development after complete curing

Typical failure on clean surfaces without any surface pre-treatment is a cohesive failure, but the adhesion depends on the specific properties of the surface.

Potential mixing ratios / Version

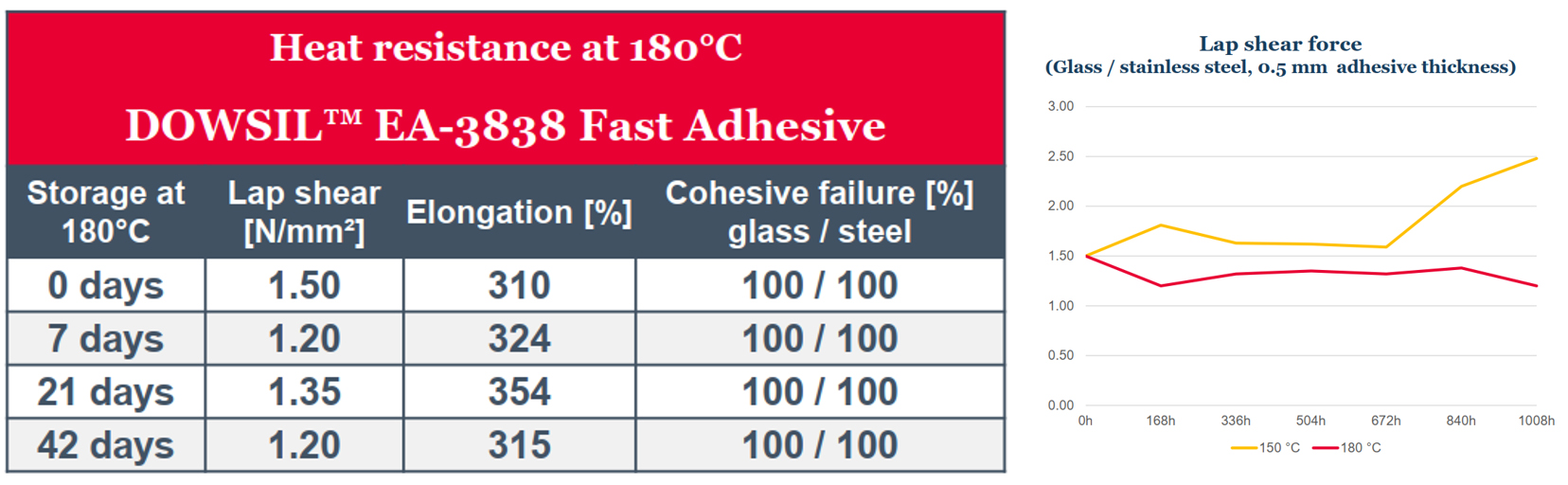

Heat resistance

DOWSIL™ EA-3838 Fast Adhesive can withstand temperatures up to 180°C and even shorter peaks at higher temperatures.

When larger adhesive areas are subjected to atmospheric contact (O2), resistance to higher temperatures could be adversely affected.

Packaging / Delivery / Storage conditions

When stored at or below 30°C in the original unopened containers, DOWSIL™ EA-3838 Fast Adhesive catalyst has a useful life of 12 months from the date of production.

Final summary

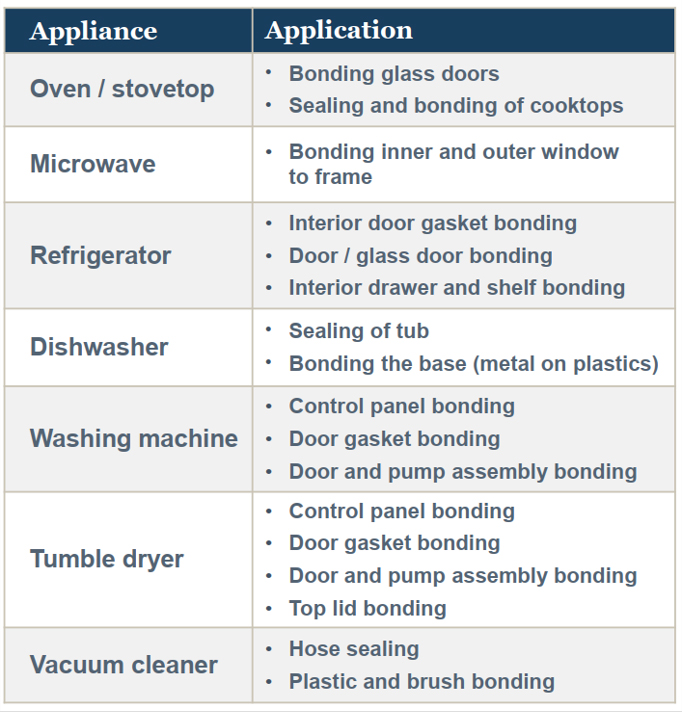

Applications – Household appliances

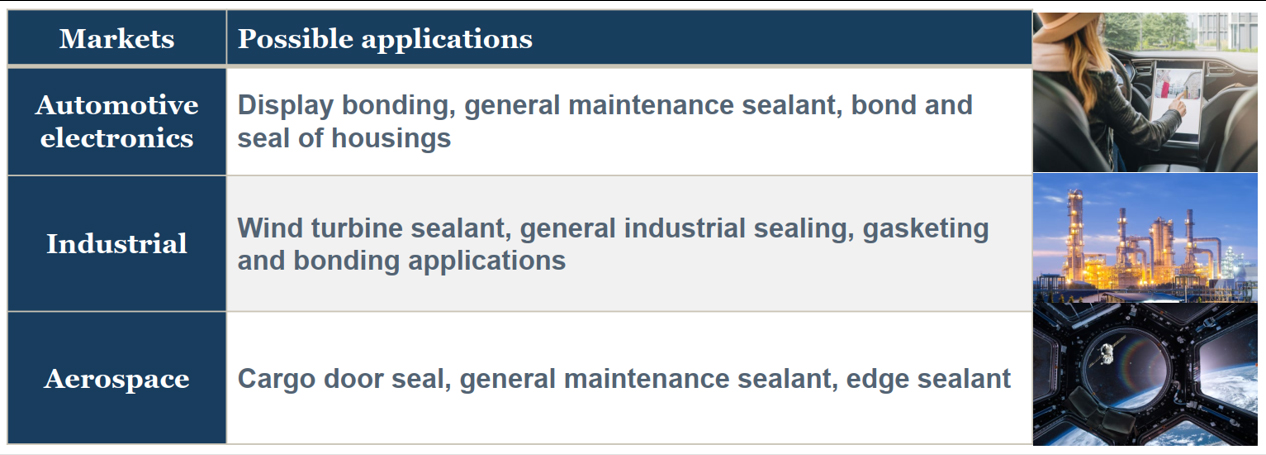

Applications – others markets

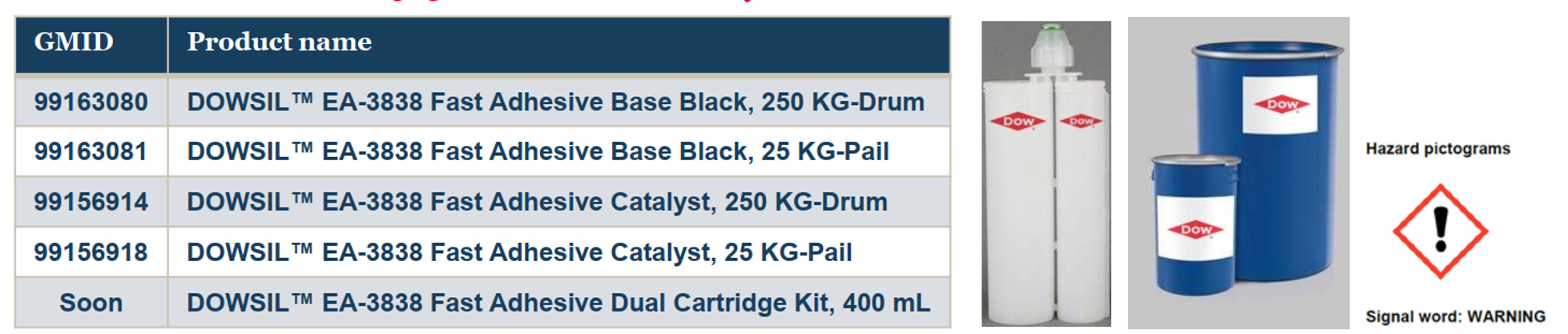

Packagings

- DOWSIL™ EA-3838 Fast Adhesive 25 kg Pail Part A

- DOWSIL™ EA-3838 Fast Adhesive 250 kg Drum part A

- DOWSIL™ EA-3838 Fast Adhesive 400 ml Cartridge

- DOWSIL™ EA-3838 Fast Adhesive 25 kg Pail Part B

- DOWSIL™ EA-3838 Fast Adhesive 250 KG Drum part B

Conclusions

DOWSIL™ EA-3838 Fast Adhesive is a two part alkoxy RTV silicone adhesive designed for applications where a strong bond is required as well as a fast cure rate and early adhesion development without priming.

Features & Benefits:

Fast curing time

Early development of adhesion without primer

Improved adhesion to multiple substrates

Improved shelf life up to 12 months

Easy and flexible mixing ratio (2:1, 3:1, 4:1)

Also available in cartridges

Main market : Household appliances

Secondary markets: Aviation, automotive, lighting and industrial

Source : Dow fast adhesive presentation

More information :

Would you like more information on the DOWSIL™ EA-3838 Fast Adhesive or on the entire product range Dowsil? Contact our technical department by telephone on 04 26 680 680 or fill in our contact form.

Download our documentation dedicated to electronic protection: