How to choose the right products? Understanding viscosity and its derivatives

A few basics to understand viscosity:

This article is intended to simplify, the terms used are simplified and are not precise.

Viscosity definition

Viscosity can be defined as all the phenomena of resistance to the movement of a fluid in a flow with or without turbulence.

In other words, viscosity defines a fluid’s ability to flow more or less rapidly.

There are two types of viscosity : dynamic viscosity and kinematic viscosity.

- Dynamic viscosity is more commonly used, as in the field of adhesives.

- Kinematic viscosity, on the other hand, is more often used for greases.

Imagine a thick syrup and water:

- Dynamic viscosity is the measure of a liquid’s resistance to flow. Syrup has a higher dynamic viscosity than water because it flows more slowly.

- Kinematic viscosity is a measure of how easily a liquid spreads. A liquid with a low kinematic viscosity spreads easily (like water), while a liquid with a high kinematic viscosity spreads more slowly (like syrup). It is obtained by dividing the dynamic viscosity by the density*.

*Density is like the weight of a certain volume of liquid. Water and syrup can have different weights for the same volume.

Viscosity unit

Dynamic viscosity

In the International System (SI), its unit of measurement is the pascal-second (Pa-s), often converted to millipascal-second (mPa-s) for low-viscosity fluids. You may find dynamic viscosity expressed in poise (Po) or centipoise (cP), which is the old CGS system unit of viscosity, still sometimes used.

For the remainder of this article, dynamic viscosity will be expressed in millipascal-seconds (mPa-s).

Kinematic viscosity

In the International System (SI), its unit is expressed in square meters per second (m²/s), convertible into cm²/s or mm²/s. It is also possible to find kinematic viscosities expressed in stokes (St = cm²/s) or centistokes (cSt = mm²/s), units from the old CGS system for more practical values, particularly in industrial contexts or for common fluids.

Viscosity measurement

Viscosity test :

Viscosity is measured with a viscometer.

There are two types, process viscometers and laboratory viscometers, the most common being the Brookfield-type rotational viscometer (laboratory viscometer).

This type of viscometer works by measuring the rotational resistance of a rotor immersed in the fluid.

Vibratory viscometers are another type of process viscometer. Some have the particularity of being able to be used in difficult industrial environments such as explosive zones, under high pressure (300 bar) and at high temperatures (300°C).

Unlike rotary viscometers, they can measure highly viscous (1,000,000 mPa-s), clogging and fibrous fluids, thanks to their high shear rate operation.

Factors to consider when testing viscosity :

- Temperature: The viscosity of most fluids decreases with increasing temperature.

- Shear rate: The viscosity of some fluids depends on the shear rate applied.

- Homogeneity: The fluid must be homogeneous before testing. The presence of air bubbles or solid particles can affect test results.

Caution: It’s important to note that viscosity is a relative property and depends on the temperature and shear rate (stress) applied.

In general, viscosity decreases with increasing temperature.

To make an analogy with everyday life, this is why the oil you pour into your frying pan liquefies as its temperature rises, because its viscosity decreases.

Thixotropic behavior

Thixotropy is a particular (rheological) property of certain fluids or materials which have the ability to vary their viscosity under the effect of stress.

A fluid or material is said to be thixotropic if, under constant stress, its apparent viscosity decreases over time.

Behavior of thixotropic fluids:

- At rest: The thixotropic fluid structures and solidifies, acquiring a high, solid-like viscosity.

- Under stress: When the fluid is subjected to stress, such as shear or agitation, its structure breaks down, lowering its viscosity and making it more fluid.

- Return time: Once the stress is removed, the fluid gradually returns to its original structure and viscosity over a period of time, known as the “return time”.

Example: Araldite 2050 PL from Huntsman.

Huntsman’s Araldite 2050 PL is a glue with thixotropic behavior, making it suitable for applications where other glues would be ineffective.

- At rest in the cartridge, it is thick and does not flow easily.

- When applied, the shearing action of the dispensing gun (applied stress) liquefies it, facilitating application.

- Once applied, it thickens again to prevent dripping.

The benefits of its thixotropic behavior can be seen, for example, when applied vertically.

NLGI consistency

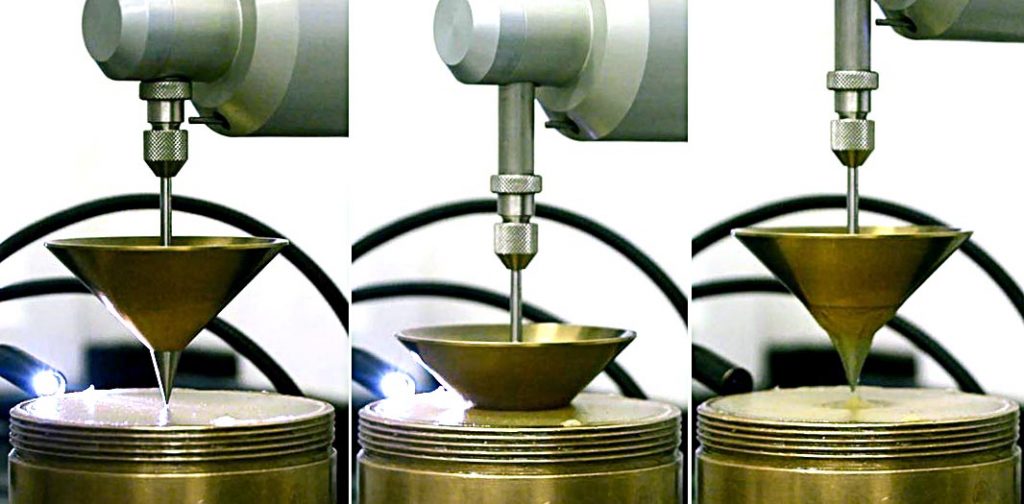

The consistency of a lubricating grease is its resistance to deformation. It is measured using a penetrometer, and is characterized by the penetrability of worked and unworked greases. It is classified according to a scale developed by the NLGI (National Lubricating Grease Institute), which gives an NLGI consistency index from 000 to 6, indicating the consistency of the grease.

To summarize the test, a conical plunger of defined size and weight is dropped from the surface of the grease (having been smoothed), allowed to penetrate it for a defined time, usually 5 seconds, then its total penetration is measured, in tenths of a millimeter, which will then assign it an index from 000 to 6.

Here is a table classifying the different NLGI consistency indexes with the appearance of the grease bearing that index:

Consistency index NLGI |

Penetration (tenths of a millimeter) |

Appearance |

| 000 | 445-475 | Very fluid |

| 00 | 400-430 | Fluid |

| 0 | 355-385 | Semi-fluid |

| 1 | 310-340 | Very soft |

| 2 | 265-295 | Soft |

| 3 | 220-250 | Semi-hard |

| 4 | 175-205 | Hard |

| 5 | 130-160 | Very hard |

| 6 | 85-115 | Extremely hard |

Viscosity in everyday life

Dynamic viscosity:

Here is a table comparing the dynamic viscosities and appearance of everyday products at 20°C and without shear:

| 0.5 mPa.s | 1 mPa.s | ~450 mPa.s | 2500 mPa.s | 10 000 mPa.s | 50 000 mPa.s | 100 000 mPa.s | 250 000 mPa.s | 1 000 000 mPa.s | 100 000 000 mPa.s |

|

|

|

|

|

|

|

|

|

|

| Gasoline (SP-98) | Water | Motor oil SAE-30 | Maple syrup | Fluid honey | Ketchup | Plain yoghurt | Peanut butter | Honeycomb | Mastic |

| – | – | Very fluid | Fluid | Semi-fluid | Self-leveling | Semi-pasty | Pasty | Semi-hard | Hard |

NLGI index :

Here is a table comparing NLGI consistency indices to the consistency of everyday products:

| 000 | 00 | 0 | 1 | 2 | 3 | 4 | 5 | 6 |

|

|

|

|

|

|

|

|

|

| Ketchup | Mashed potatoes | Chestnut cream | Mayonnaise | Peanut butter | Soft butter | Ice cream | Soft toffee | Cheddar |

| Very fluid | Fluid | Semi-fluid | Very soft | Soft | Semi-hard | Hard | Very hard | Extremely hard |

Why is viscosity important when choosing product references?

-

Product performance :

- Lubricants: The viscosity of engine oils, for example, is crucial to ensuring adequate engine lubrication at different temperatures. An oil that is too viscous may not flow properly at low temperatures, while one that is too fluid may not provide sufficient protection at high temperatures.

- Paints: The viscosity of paint influences its spreadability, coverage and drying time.

- Food products: The viscosity of sauces, ice creams and other food products affects their texture, mouthfeel and freeze/thaw behavior.

- Cosmetics: The viscosity of creams, gels and lotions influences their application, absorption and feel on the skin.

-

Product quality :

- Quality control: Viscosity can be used as an indicator of product quality.

- Defect detection: Unexpected changes in viscosity can indicate product deterioration.

-

Safety and ergonomics :

- Safety: The viscosity of some products may have safety implications.

- Ergonomics: The viscosity of a product can affect its ease of use. For example, a thermal paste that’s too viscous can be difficult to apply, while a product that’s too fluid can flow too quickly and cause damage.

Conclusion

This information clearly shows that viscosity is a crucial property for the optimal performance of many products in different industrial sectors. A thorough understanding of viscosity and its effects can help to select the most suitable products for specific applications, ensuring reliable, long-lasting performance.

Remember that viscosity is a complex property that can be influenced by a variety of factors, and is just one of many factors to consider when choosing the right reference for your application. Contact us for specific recommendations and information.