What does “food grade” mean for industrial lubricants?

To ensure effective lubrication, it is crucial to meticulously prepare the surface of the materials to be lubricated before any application.

With this in mind, Samaro and its partner Socomore recommend the use of Diestone DLS. It is a chlorinated hydrocarbon-free cleaner and degreaser that evaporates quickly, providing ideal surface preparation for effective lubrication.

Ensuring the safety and quality of food and beverage manufacturing processes is crucial, requiring the use of lubricants that do not compromise product integrity. Imagine your favourite fizzy drink contaminated with a harmful substance during production; the first sip would be far from pleasant and could even be dangerous depending on the chemical compounds! So how are standards maintained for food, water and consumer products? This is where NSF International comes in, an independent organisation dedicated to maintaining these standards.

What is an “NSF H1 certified” lubricant?

This certification represents the highest level of food safety, meaning that the lubricant is suitable for situations where accidental contact with food may occur (up to 10 ppm). H1 lubricants are odourless, tasteless and chemically inert, guaranteeing effective lubrication with no risk of product contamination.

What about “NSF H2 certified”?

NSF H2 certified” lubricants are intended for equipment that does not come into direct contact with food, such as forklift trucks or compression systems outside food production areas. They undergo rigorous refining processes and must not contain carcinogens, heavy metals, mutagens, mineral acids or other harmful substances.

The importance of food-grade lubricants for food and beverage companies

For companies in this sector, guaranteeing customer safety and product quality is paramount. That’s where MOLYKOTE® food grade lubricants come in, offering solutions that comply with strict food safety standards, giving peace of mind to manufacturers and consumers alike.

Food grade lubricants: increased resistance to emulsification

DuPont MOLYKOTE® lubricants are carefully engineered to achieve maximum saturation, eliminating nucleation sites that could promote water binding. This water resistance persists throughout the life of the lubricant, providing exceptional protection for equipment subjected to frequent washdowns, while maintaining optimum performance.

Wide temperature range – from freezing to intense heat

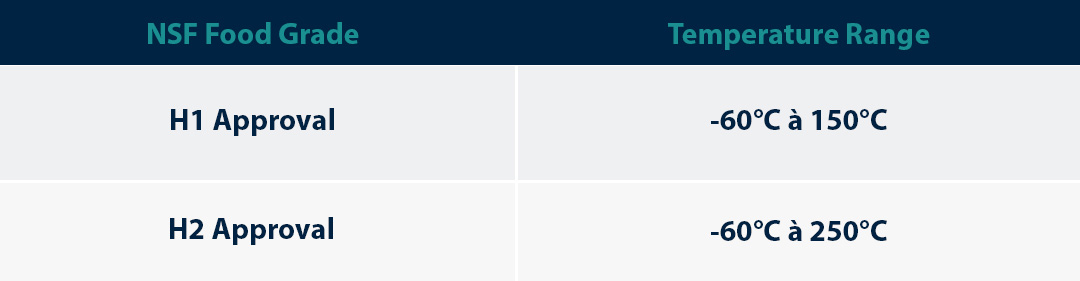

In the food and beverage industry, where operations are often subject to extreme temperature variations, MOLYKOTE® lubricants offer a variety of H1 and H2 formulations with outstanding temperature stability.

Highly refined for superior quality

Renowned for their exceptionally refined bases, MOLYKOTE® high performance lubricants offer a number of benefits in demanding production environments, including:

- Extended drain intervals : Reduced lubricant consumption and costs.

- Cleaner, longer running: Improved equipment longevity and reduced maintenance requirements.

MOLYKOTE® Food Grade

This range includes high-performance oils, greases and pastes designed to meet rigorous food safety standards.