Dowsil – How to bond and dissipate heat from electronic devices ?

How to improve the thermal dissipation of your electronic assemblies ?

Dow, with its product range Dowsil™, has developed thermally conductive adhesives with the same advantages as standard adhesives with the added feature of thermal conductivity.

These Dowsil™ adhesives are used where a permanent bond is desired, where mechanical fixation is not possible or undesirable, where thermal movement is required to articulate the bond, and where maintenance or rework is unlikely to be required.

Thermally conductive adhesives are ideally suited for bonding power components, heat sinks and other applications where flexibility and thermal conductivity are major concerns.

Heat-curing fluid versions are also suitable for transformers, power supplies, coils and other electronic devices where improved thermal conductivity is required.

Silicones generate very little stress on components even when containing thermally conductive fillers.

Translated with www.DeepL.com/Translator (free version)

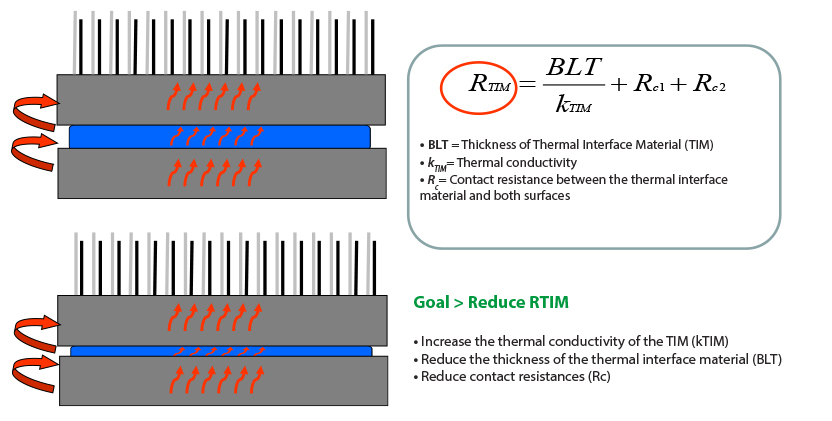

Why are Thermal Interface Materials (TIMs) necessary? Or how to reduce thermal resistance?

Even when the surfaces of two components are in direct contact, the difference in surface finish (roughness) creates voids (gaps). Air trapped in these voids will then limit heat transfer.

TIMs will therefore help to close the gap between two components and promote heat transfer by reducing thermal resistance.

Silicones Dowsil™ curing at room temperature RTV

| References | Properties | Thermal conductivity (W/m.K) |

Viscosity (mPa.s) | Shore | Tensile strength (MPa) |

Elongation (%) | Temperature Range | Rigidité diélectrique (kV/mm) | Conditionnements |

|---|---|---|---|---|---|---|---|---|---|

| Dowsil™ SE 4485 |

Blanc – UL 94 V0 |

2.8 | NA | A90 | 3.4 | 20 | -40°C / +120°C | 19 | 330 ml Cartridge |

| Dowsil™ TC 1500 |

Blanc | 1.55 | NA | A82 | 2.7 | NC | -45°C / +200°C | 18 | 330 ml Cartridge |

| Dowsil™ SE 4420 |

Blanc | 0.92 | 108 000 | A76 | 4.1 | 77 | -45°C / +200°C | 14.6 | 330 ml Cartridge |

HTV hot-curing silicones Dowsil™

Dowsil™ silicones are available in fluid versions for hot curing where improved thermal conductivity is required.

| References | Properties | Thermal conductivity (W/m.K) |

Viscosity (mPa.s) |

Shore | Tensile strength (MPa) |

Elongation (%) | Temperature Range | Dielectric strength (kV/mm) |

Packaging |

|---|---|---|---|---|---|---|---|---|---|

| Dowsil™ TC 2035 |

Red – Two part | 3.3 | 125 000 | A95 | 3.6 | 43 | -40°C / +200°C | 21 | Kit 2 kg – 3.2 kg |

| Dowsil™ SE 4450 |

Grey – One part | 1.92 | 66 000 | A95 | 6.7 | 46 | -45°C / +200°C | 21 | 1 kg Can |

| Dowsil™ 1-4173 |

Grey – One part | 1.8 | 61 000 | A92 | 6.2 | 20 | -45°C / +200°C | 16.7 | Cartridge 75 ml 1.5 kg Cartridge |

Permabond epoxy and acrylic adhesives

The excellent chemical resistance of epoxy resins makes them suitable for severe environmental conditions. Permabond acrylic adhesives have a very fast setting time, allowing for a high yield.

| References | Properties | Thermal conductivity (W/m.K) |

Viscosity (mPa.s) |

Shore | Tensile strength (MPa) |

Elongation (%) | Temperature Range | Dielectric strength (kV/mm) |

Packaging |

|---|---|---|---|---|---|---|---|---|---|

| Permabond MT3826 |

Yellow – Two part composant – hybrid epoxy – Handling time : 2-3h | 1.4 – 1.6 | 350 000 | A55 | 1-2 | >80 | -40°C / +150°C | 18-20 | 400 ml Cartridge |

| Permabond TA4392 |

Acrylic – White – One part – Handling time : 2-3 min | 1.11 | 200 000 – 400 000 | D65 | 15-20 | 1.5 | -55°C / +100°C | 25-30 | 300 ml Cartridge |

More informations :

Need information on Dowsil™ or Permabond ? Contact our technical department on +33 426 680 680 or fill in our contact form.

You can also download our selection guide dedicated to thermal management :