Molykote® D-6600 Anti-Friction Coating

Molykote® D-6600 Anti-Friction Coating

Molykote® D-6600 Anti-Friction Coating is a durable coating with a low coefficient of friction and good adhesion to metal. A reliable coating for clean, long-lasting lubrication.

Consumers demand reliable and durable cars. Expectations for extended durability are no less high for high-stress components such as starters. Developed from proven Smart Lubrication™ solutions, MOLYKOTE® D-6600 antifriction coating delivers long-lasting performance that meets Tier 1 specifications while using standard equipment for spray or dip coating processes.

MOLYKOTE® D-6600 Antifriction Coating is a highly durable coating with a low coefficient of friction and good adhesion to metal. This dry film lubricant is suitable for permanent lubrication of metal/metal and metal/plastic couples involving slow to medium rapid motion and medium to low pressure conditions. It can be used when oils or greases cannot be used for technical reasons or are not desirable due to the risk of fouling. MOLYKOTE® D-6600 anti-friction coating has been proven in start-up engine cycle tests and has many potential applications for metal parts such as door locks and metal/plastic contacts such as ball joints and window regulators.

Product description

- Organic and polymeric resin system

- Solid organic lubricants

- Solvent

- Development objective: New generation of organic solid lubricants based on an anti-friction coating with a very low coefficient of friction and long life.

Performance and benefits

- Excellent dry lubrication properties

- Excellent adhesion to metals

- Excellent load carrying capacity and low coefficient of friction at medium and low pressures

- Excellent wear protection

- Low coefficient of friction for metal/plastic combinations, especially at medium and low pressures

- Good corrosion protection

Key Benefits

- Allows for long-term dry lubrication of metal-to-metal components at medium and low contact pressures.

- Allows dry lubrication of metal/plastic components for the life of the component.

- Allows for dry lubrication of components when a fluid (oil/grease) is not desired or possible.

Benefits for tough automotive applications

- Lubrication of starter motor

Features

These values are not intended to be used in the preparation of specifications. Please contact your local MOLYKOTE® sales representative before writing specifications for this product.

| Standard | Properties | Molykote D-6600 Anti-Friction Coating |

|---|---|---|

| Color (dry cured film) | Yellowish | |

| Operating temperature range (cured film) | -40 to +260°C | |

| Properties | ||

| DIN EN ISO 2431 | Viscosity to 23°C | 32 s |

| ASTM D1475 | Density to 23°C | 0.93 g/ml |

| ASTM D56 | Flash point | 26°C |

| Load capacity, wear protection, service life | ||

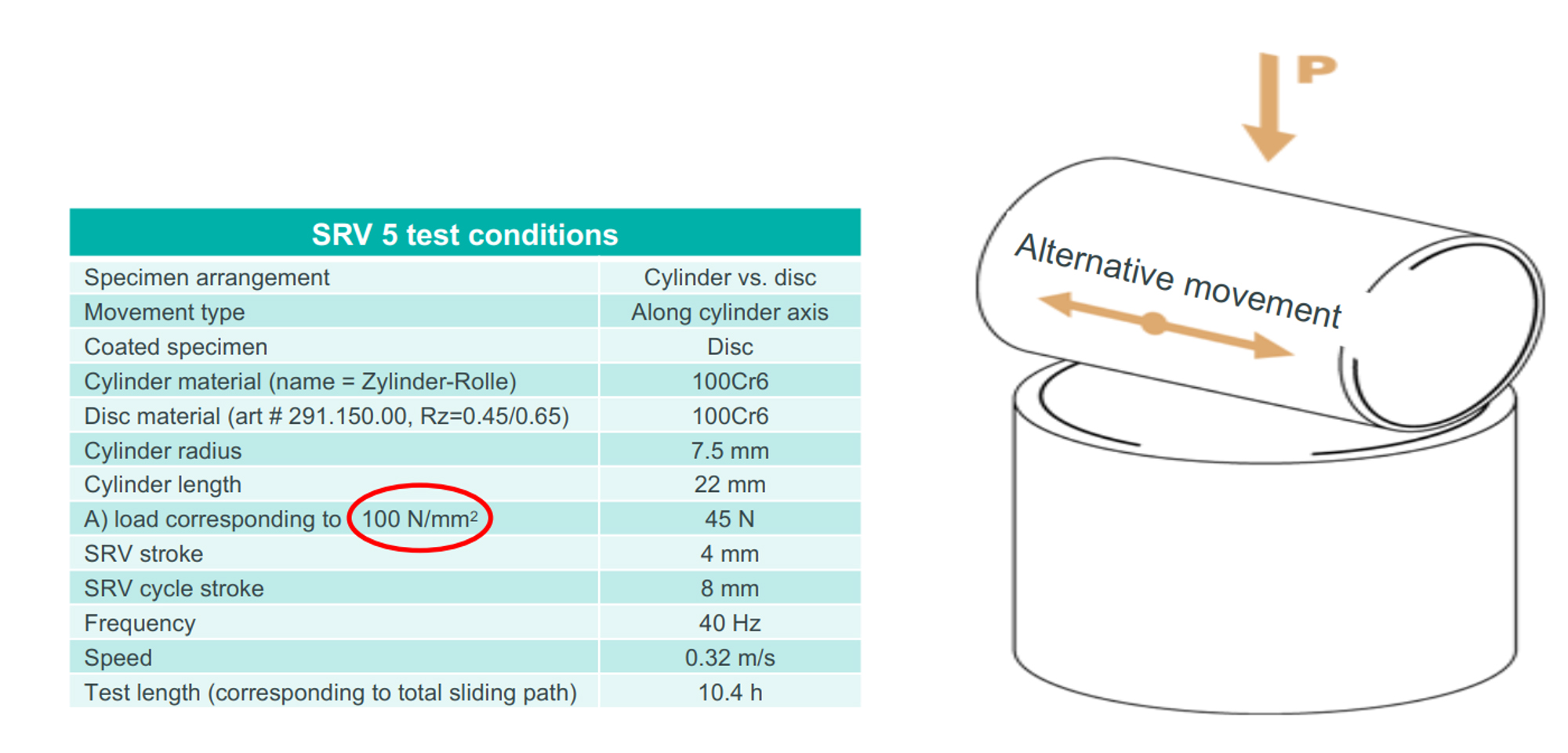

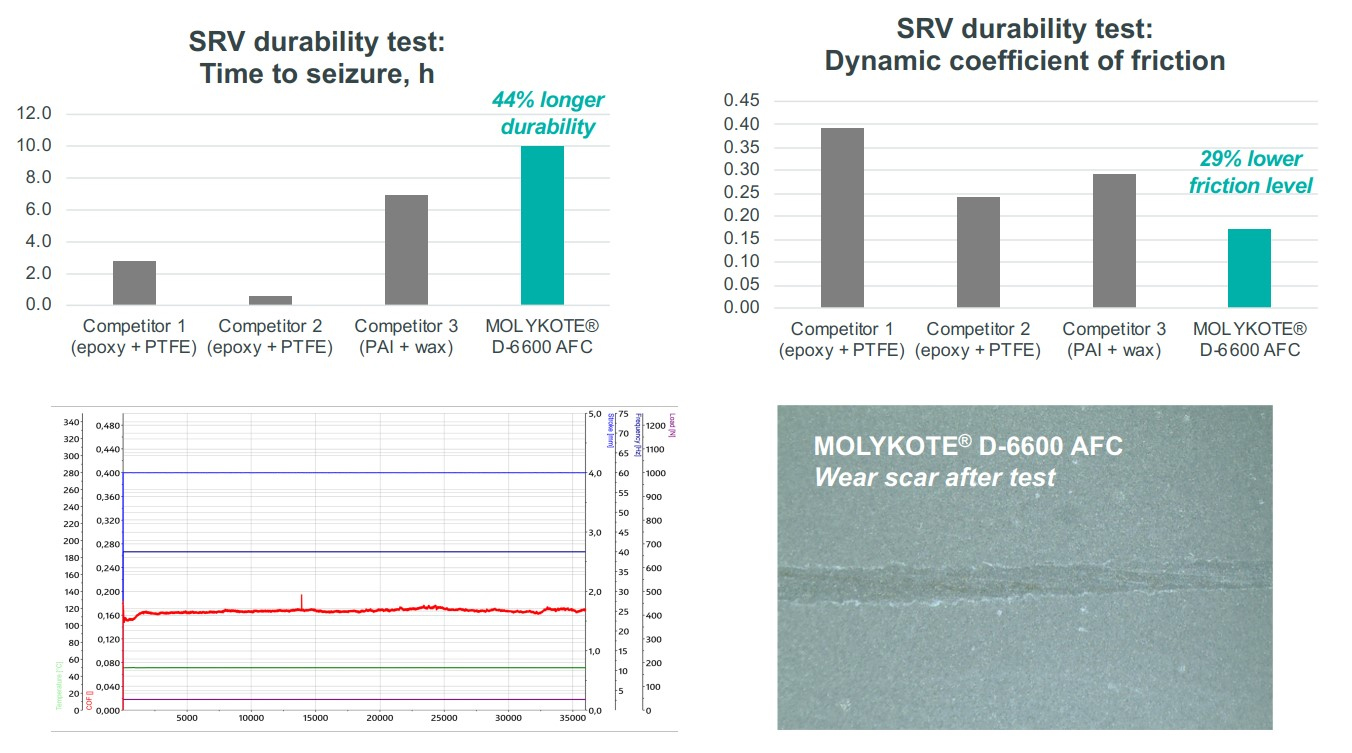

| DIN 51834 | SRV, durability in endurance, cylinder (15×22 mm) / disc, load 45 N (100N/mm²), speed 0,32 m/s, 50°C, 40% relative humidity, dry condition | s>10h, COF (µ)=0,17 |

| DIN 51834 | SRV, durability in endurance, cylinder (11×15 mm) / disc, load 130 N (240N/mm²), speed 0,15 m/s, 23°C, 40% relative humidity, dry condition | Mn>48h, COF (µ)=0,15 |

| VDA 230-206 | Noise tester, 2500 cycle endurance test, POM ball vs. steel, load 30 N (120 N/mm²), velocity 2mm/s, 23°C, 40% relative humidity, dry condition | COF (µ)= 0.10, pas de bruit |

Method of application

- Hot curing system; the recommended curing program is 20 minutes at 200ºC (object temperature time).

- Other curing programs (i.e. reduced curing time) may be possible; they should be tested for each case.

- Recommended dry film thickness: 10-15 µm (typical RAF)

- Preferred application methods:

- Spraying

- Dip spinning (for this process the viscosity can be adjusted according to the shape and size of the parts to be coated)

- Thinner and cleaner for application equipment: MOLYKOTE® L-13 thinner

- Calculated yield (excluding losses due to the application process): approx. 18 m2/kg for a dry film thickness of 12 µm.

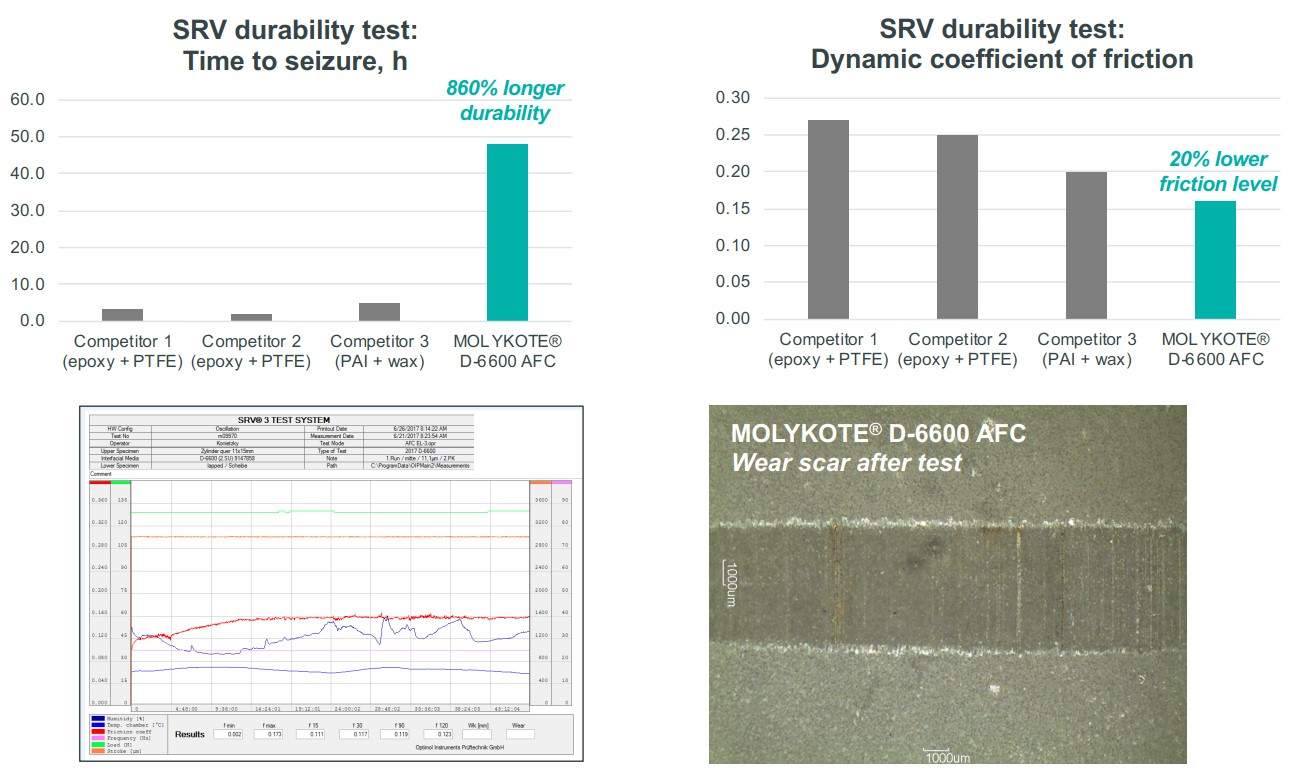

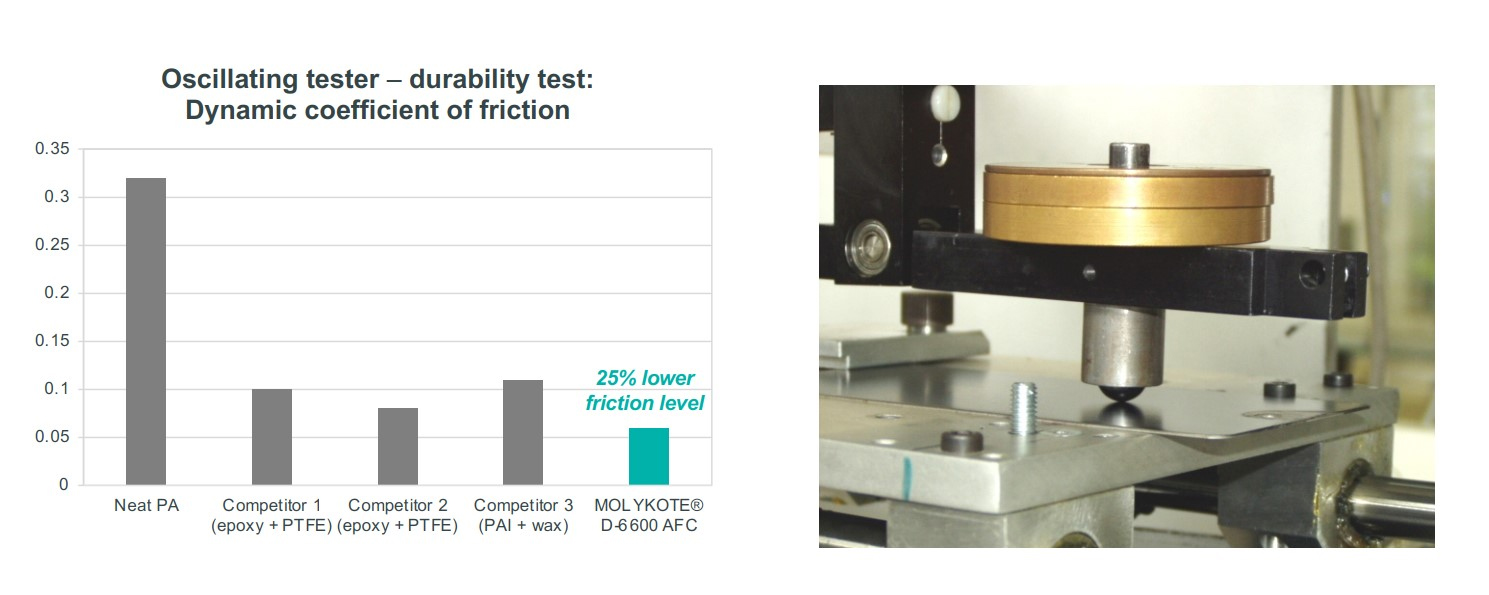

Low Pressure Steel to Steel Pairing Test: Conditions

- Durability test

- Simulation of an automotive application

Low Pressure Steel to Steel Pairing Test: Results

Steel/steel pairing test at medium pressure: Conditions

- Durability test

- Simulation of an automotive application

- Cylinder (diameter: 11 mm; length: 15 mm)

- Disc (100Cr6)

- Parameters:

- Stroke: 3 mm

- Frequency: 25 Hz

- Load: 130 N

- Contact pressure (theoretical): 250 MPa

- Ambient temperature conditions

- Dry lubrication (only AFC)

- AFC applied on the disc

- Test machine SRV III DC

- Pretreatment : Phosphating with Mn

Steel/steel pairing test at medium pressure: Results

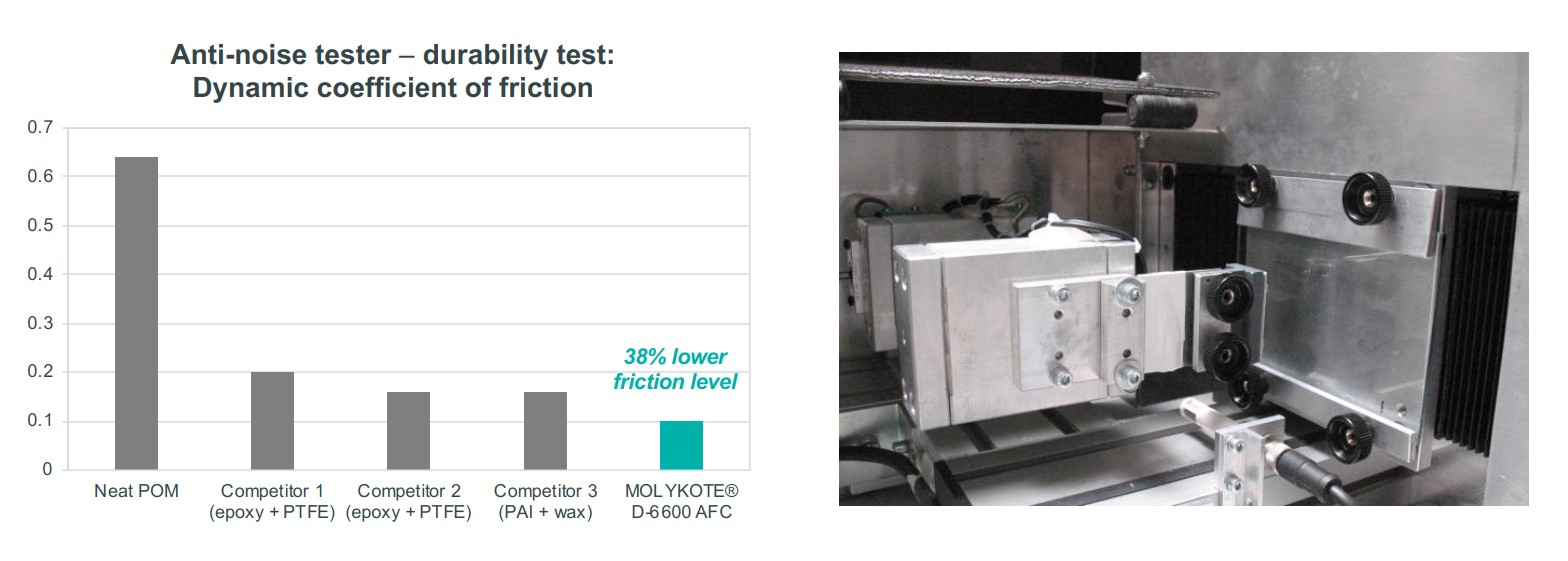

POM/Steel Material Matching Test: Conditions

- Noise tester

- According to VDA 230-206 test procedure

- POM versus coated steel

- Material pair Plastic ball (see picture)

- Ball diameter: 12.7 mm

- Stroke: +/- 2.5 mm

- Speed: 2 mm/s

- Load : 30 N

- POM ball: theoretical pressure: 120 N/mm2

- Climatic conditions: room temperature (23ºC, 45% RH)

- Test duration: 2,500 cycles (durability test, about 4 h)

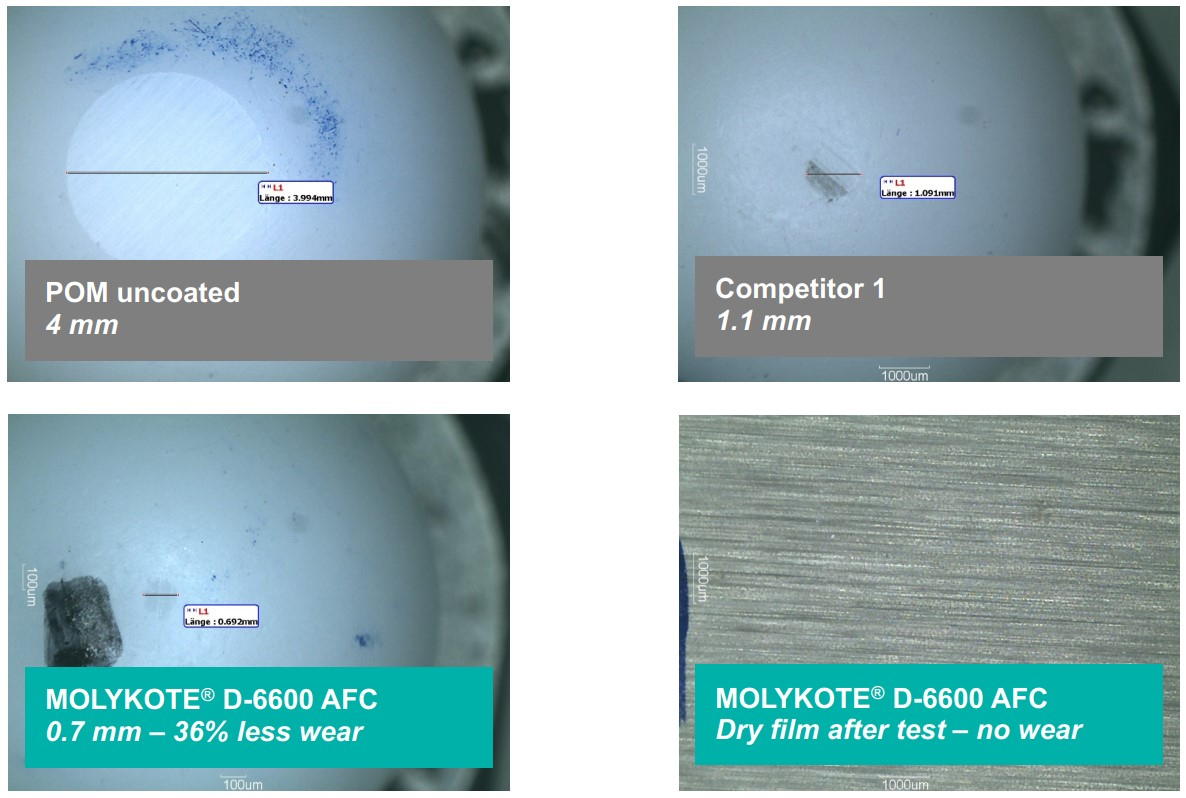

POM/Steel Material Matching Test: Results

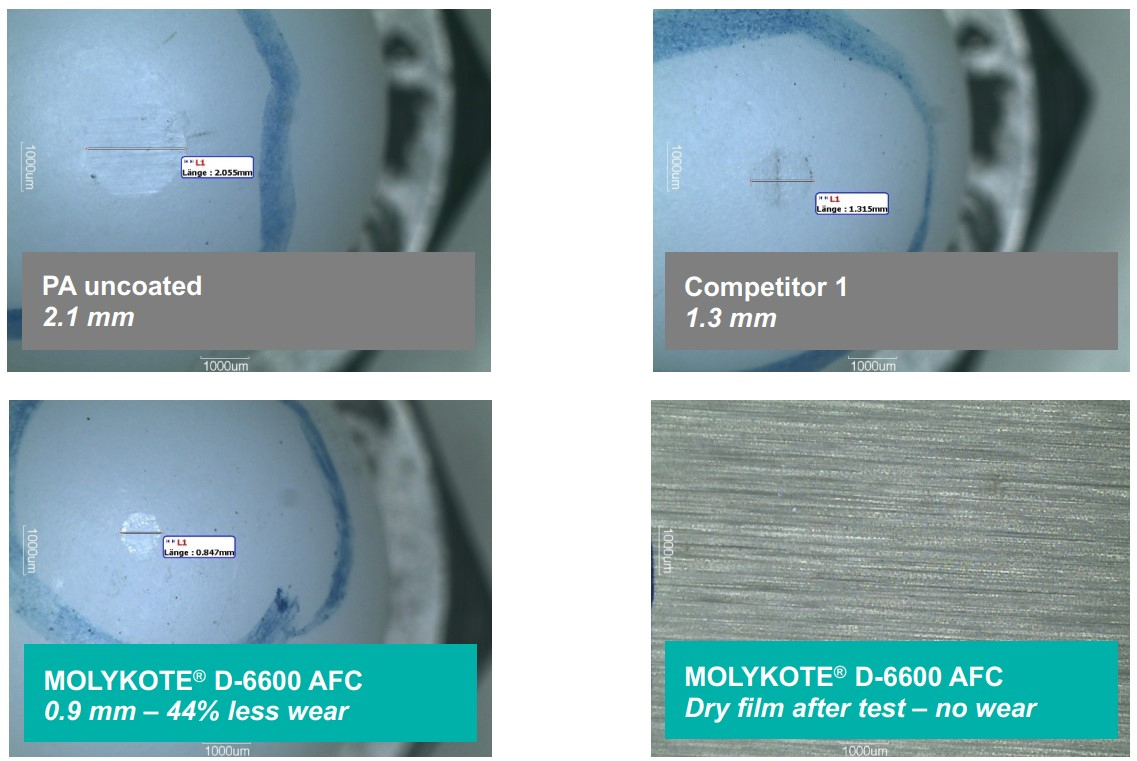

Wear marks – POM ball after testing

PA/steel matching test : Conditions

- Oscillating tester

- PA vs. coated steel

- Material torque Plastic ball

- Ball diameter : 12,7 mm

- Stroke : +/- 4,5 cm

- Speed : 5 cm/s

- Load : 7 N

- For the PA 6.6 ball: theoretical pressure: 60 N/mm2

- Climatic conditions: room temperature (23ºC, 45% RH)

- Test duration: durability test, 1 h (1000 cycles)

PA/Steel Matching Test: Results

Wear marks – PA ball after testing

Corrosion Protection Performance Test: Conditions

- Evaluated by salt spray test (ISO 9227)

- The anti-friction coating works on the concept of isolating the coated surface from the environment.

- The corrosion protection depends on :

- the type of substrate material

- the surface pre-treatment

- the shape/type of the coated parts (flat, edged, hollow, etc.)

- Application processDry film thickness

Corrosion Protection Performance Test: Results

Appropriate applications

- Lock components under medium pressure (pawls, locking plates, levers)

- Seatbelt system components

- Seating system springs

- Armature cylinders (e.g. starters)

- Suspension system ball joints

- Stainless steel threaded connections

Key messages to remember MOLYKOTE® D-6600 anti-friction coating:

- Significantly improves dry lubrication life of metal-to-metal mating components under low and medium contact pressures.

- Significantly improves dry lubrication life of plastic/metal mating components.

- Can provide good corrosion protection

- Can be applied to parts using traditional painting processes and equipment.

More info :

Needs information about the brand of industrial lubricants Molykote®? Contact our technical service by phone to +33 426 680 680 or fill our Contact form.

Source : dge-europe.com