DOWSIL™ EI-2888 Primerless silicone encapsulant

![]() DOWSIL™ EI-2888 – The lighting market and its challenges

DOWSIL™ EI-2888 – The lighting market and its challenges

Stick to the clear benefit.

Growth and impact on the planet

The global LED lighting market is expected to reach $100 billion over the next decade. This corresponds to a compound annual growth rate of over 12% in value and over 20% in volume.

Lighting-related energy consumption is expected to decline by 40% by 2030, driven by LED penetration in general lighting.

![]()

Meeting the needs of the professional lighting market

The professional LED lighting market is expected to exceed $35 billion by 2022. This includes industrial, commercial, outdoor and architectural applications.

The key growth drivers are related to expectations of:

- High efficiency

- Reliability and robustness

- High brightness

- Compact size and custom shapes

- Low energy consumption

The need for a high level of protection against intrusion

- Flexible and Rigid LED Strip Lights

- Outdoor LED Displays

- Explosion proof lighting

- Linear: Tube and Cord/Tape

- Spot, flood and general area

- Small portable type: Flashlights, portable headlamps

- Specialty and Panel

Protective materials on LEDs

Protection options

Conformal coatings

- Minimal effects on luminous flux and CCT

- Challenge: Provide as little protection as possible over bare components.

Optical encapsulant

- Provides the highest degree of protection and ease of use

- Challenge: Impact on the CCRS

Molded lens

- Better optical management

- Challenge: Lower degree of protection (air gap) and more complex impact price

Encapsulation is best suited for harsh environments, such as explosion-proof or high IP-rated fixtures.

Protection and performance

DOWSIL™ EI-2888 encapsulant compared to other solutions.

![]()

Watch a video to see the benefits of DOWSIL™ EI-2888 Primerless Silicone Encapsulant

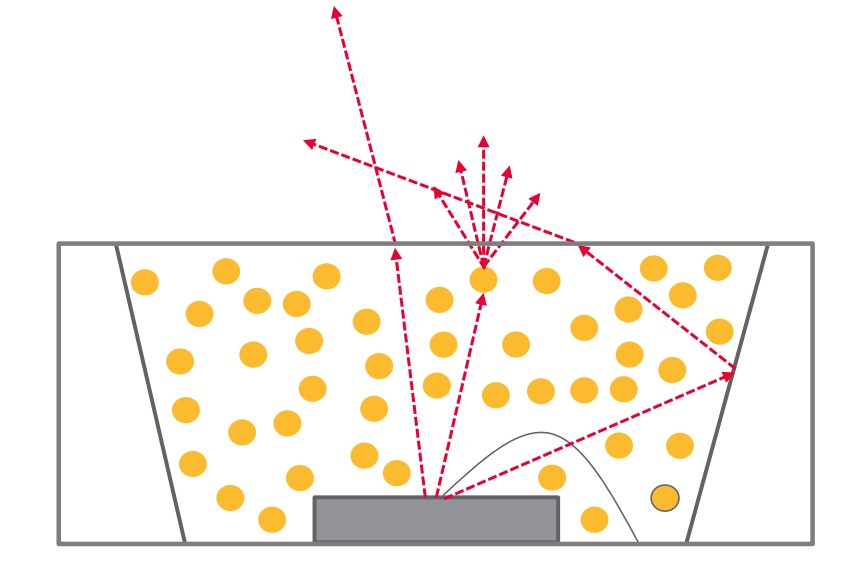

Optical influence

The protective material can :

- change the Fresnel reflection

- change the color of the converted light

- change the total internal reflection

![]()

Existing encapsulation materials

![]()

![]()

Innovate with DOWSIL™ EI-2888 primerless silicone encapsulant.

![]()

Innovative technology from Dow

- Patented technology

- 100% silicone product

![]()

![]()

self-adhesive

Reliable membership on :

- Anodized aluminum

- Glass

- FR4

- Stainless steel

- Steel

- Polycarbonate

- PBT

- Copper

Even after 2000 hours of exposure to :

- 150ºC

- 85ºC / 85% RH

- -40 / +150ºC thermal shock

- Sunlight UV

Limitation: PMMA, die-cast aluminum

![]()

Optically clear in a difficult environment

![]()

Optically stable beyond the visible range and under the effect of aging

![]()

Proven results

Two rigid, high power LED modules using DOWSIL™ EI-2888 encapsulant.

![]()

Resistance of the polymerization

- Not subject to inhibition during curing

- Common problem with silicone-based encapsulants

- Insensitive to moisture during cure ≠ urethane

- No need for controlled atmosphere

- Reduced need for cleaning

Potential cost reduction

![]()

Ease of degassing

- Suitable for various mixing techniques, such as hand mixing, static mixing, dynamic mixing and centrifuging.

- No need for vacuum after application

![]()

Low viscosity

| Part A | 2,000 mPa.s |

| Part B | 2,300 mPa.s |

| Mélange | 2,700 mPa.s |

Mix Ratio = 1:1

Flexibility and robustness

![]()

![]()

Curing time / Hardness to define your process

![]()

Stable with age

![]()

Good dielectric properties

| Properties | Values |

| Dielectric strength | 19kV/mm |

| Volume resistivity | 1E+16 Ω.cm |

| Surface resistivity | 2,6E+14 Ω |

![]()

Long service life

- Expected stability of one year

- Keep package closed – avoid moisture

- Moisture contamination reduces cure rate

![]()

Additional unique feature

![]()

Final Comparison / Wrap-up

![]()

Price positioning

![]()

More info :

Would you like more information on DOWSIL™ EI-2888 Encapsulant silicone primerless or the entire Dowsil product line ? Contact our technical service by phone at 04 26 680 680 or fill out our contact form.

Download our documentation dedicated to electronic protection: