DOWSIL™ CC-8030, this tropicalisation coating with two curing modes: moisture or UV

Serving PCB manufacturers and system assemblers for decades

For over 75 years, Dowsil’s technology offerings have helped PCB and assembly system manufacturers across the value chain bridge the gap between

breakthrough innovation and success.

Innovations in advanced materials

A broad portfolio of silicone, polyurethane and hybrid technologies addressing the different needs of the value chain and end-use applications:

- Adhesives and sealants

- Conformal coatings

- Encapsulants

- Dielectric gels

- Electrically and thermally conductive materials

- Bonding

- Sealing

- Protection

- Stress relief

- Heat dissipation

- EMI shielding

- Assembly

- Mil spec

- Ease of processing

Possible curing profiles: tropicalisation varnish

Fast moisture curing

These coatings cure quickly at room temperature to provide a ‘drop and forget’ option that is non-sticky and ready to run on the production line in less than 10 minutes, making it an ideal option for high volume assembly operations.

Moisture curing with extended working time

Silicone coatings in this category also cure at room temperature but allow more time for the product to flow on large or complex boards. They are also the preferred option for applications that require a thicker coating.

Heat curing

Sometimes referred to as “controlled cure” for the control they allow over the cure rate, coatings in this category are the material of choice when your processing operation requires complete cure in less than five minutes. They can also place less stress on board components during the thermal cycle.

NOW: Double UV and moisture curing

DOWSIL™ CC-8030 cures in seconds with secondary moisture cure for shadow areas. Designed for automated spray coating, in-line processing to reduce space requirements.

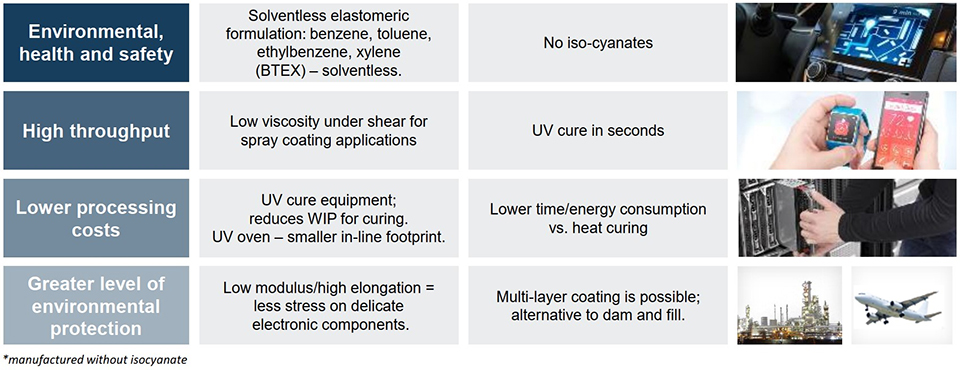

Dual UV and moisture cured silicones: A distinct combination of characteristics

Environment

Solvent free BTEX*, and the UV curing of this product significantly improves performance, provides an environmentally sustainable environment for workers and saves energy consumption compared to heat curing.

Processing

- A tropicalisation coating designed for spray treatment.

- Fast curing by exposure to a wide spectrum of UV light (mercury lamp).

- Secondary moisture curing for shaded areas.

Stress relief

- Low modulus of elasticity.

- High elongation.

- Improves reliability against stress.

The most distinct features of silicones can now be harnessed with the speed of UV curing. DOWSIL™ CC-8030 Dual Moisture Cure Conformal Coating is solvent free, being manufactured without added solvent.

Trends in Conformal Coatings

General segment trends and implications for tropicalisation coatings.

- Integrated system

- Improved dielectric protection

- Smaller devices

- Higher speed

- Modular

- Environmentally friendly

- Low power consumption

- Smaller circuit boards and electronic components versus increased power and efficiency

- Use of electronic components in very harsh environments

- Increased need for protection of electronic circuits

Product requirements for conformal coatings

- For more challenging environments:

- Excellent protection in high humidity environments

- Protection against contamination

- Excellent flame retardant and electrical properties

- Regulations :

- Less VOCs

- Solvent free

- Solvent free BTEX

- UV curing

- Moisture curing coatings (100% solid silicones)

Key trends in conformal coatings that DOWSIL™ CC-8030 addresses.

DOWSIL™ CC-8030

- Colour: Translucent

- Viscosity (cP)*: 520

- Adhesion free time at 25ºC: UV curing seconds

- UV curing conditions (type H bulb)** : 2000 mJ/cm2

- Hardness, shore A: 30

- Tensile strength: 120 psi

- Elongation: 85%.

- Dielectric strength (V/mil): 575

The information presented here is for illustrative purposes only and should not be construed as a product specification.

*High viscosity of the shear cone and plate

**Standard mercury H-lamp/bulb broad spectrum UV lamp (spectrum in UV A, UV B and UV C)

Features and benefits: sustainable and environmentally friendly treatment

- Does NOT contain benzene, toluene, ethylbenzene or xylene.

- No added solvents and sprayable.

- No isocyanates

- Secondary moisture is a neutral cure

- Fast UV primary cure;

- Reduces the need for high temperature ovens.

- Reduces floor space for set-up of WIP

- Reduced curing time

Sustainable and environmentally friendly processing.

*

*

Global economy :

- Reduce curing temperature

- Reduce cure time

- Reduce processing area and capital by minimising WIP steps and large ovens.

- Increased overall yield

Features and benefits: High efficiency

Designed for fast online processing

- Rheology designed for spray coating

- Extended working time in the dispensing line

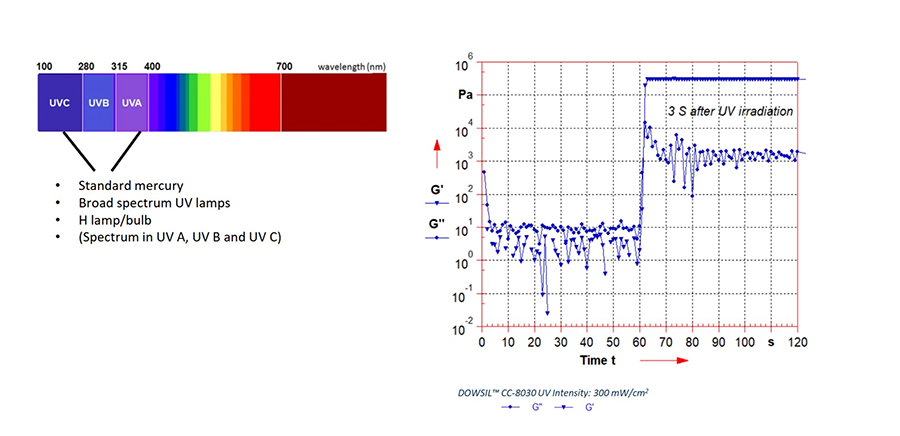

- UV curing in less than a minute – standard mercury broad spectrum UV lamp; H lamp/ampoule (UV A, UV B and UV C spectrum)

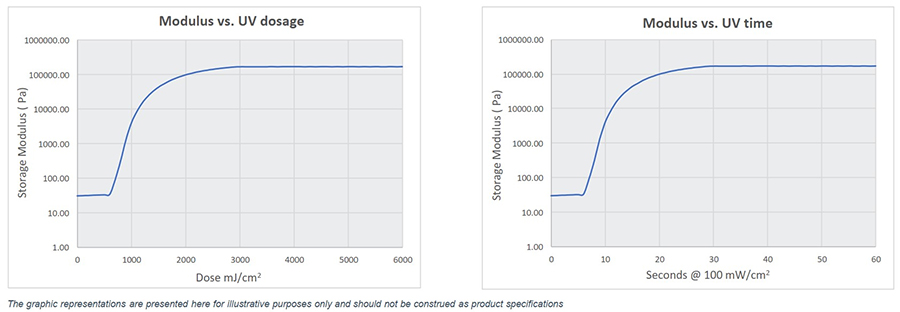

Features and benefits of DOWSIL™ CC-8030: fast UV curing

- Adhesive free after less than 10 seconds @300 mW/cm2

- No oxygen inhibition

Features and benefits: fast UV curing

- Standard mercury

- Broad spectrum UV lamps

- H lamp/ampoule

- (Spectrum in UV A, UV B and UV C)

| Time (s) | Intensity (mW/cm2) |

|---|---|

| 7 | 300 |

| 10 | 200 |

| 20 | 100 |

| 40 | 50 |

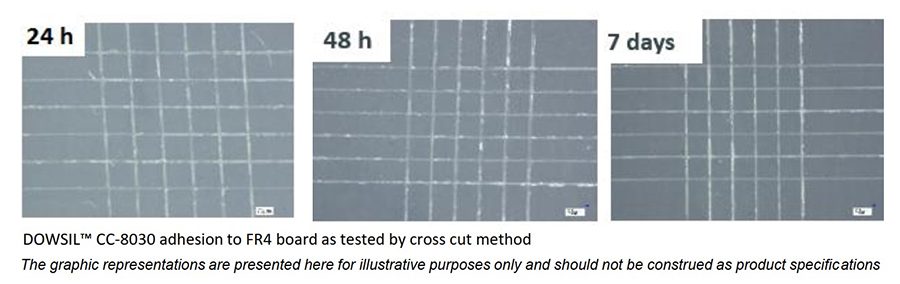

Benefits of DOWSIL™ CC-8030: Adhesion

- Demonstrated good adhesion to typical electronic substrates.

- Good adhesion to cured silicone materials.

Features and benefits: higher level of protection.

- Improves reliability in wet environments

- Wider operating temperature range of -45 to 200°C

- Protects PCBs and other electronic components from environmental particles, moisture and contaminants, reducing short circuits and corrosion of conductors and solder joints

- Good dielectric properties (insulation, moisture resistance, breakdown voltage)

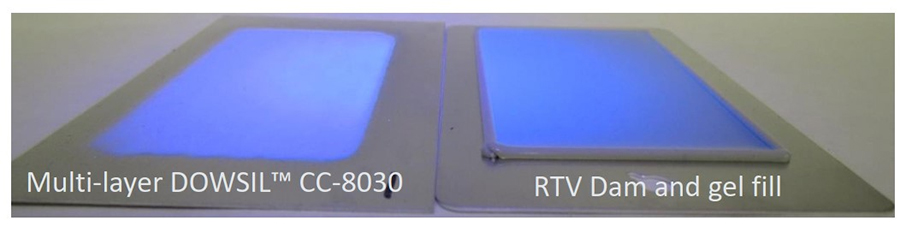

- Rheology designed for single layer spray coating from 2 to 8 mils (50 to 200 µ)

- The use of a multilayer coating to achieve 15 to 25 mils (380 to 635 µ) is possible with DOWSIL™ CC-8030. This allows the replacement of the traditional dam and fill.

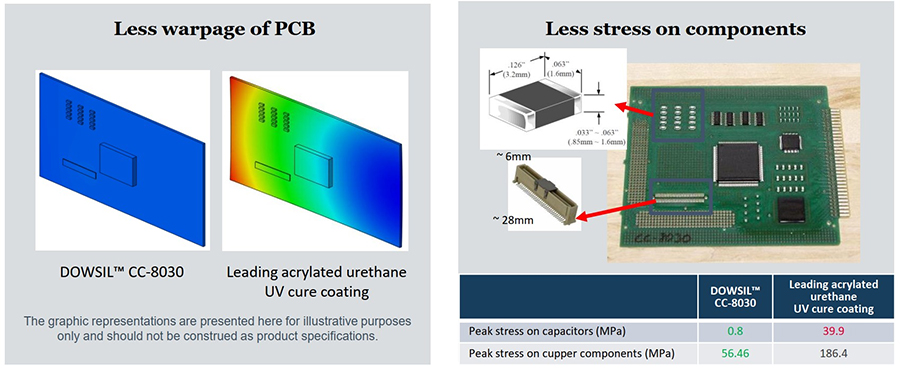

USP: Low modulus for delicate components

Compared to leading acrylated urethane-based UV-cured coatings, DOWSIL™ CC-8030 offers significantly improved system reliability.

Industry specifications

- Pending :

- Underwriters Laboratory : UL 94

- Flammability test

- IPC 830

- Standard for non-military application

How are the tropicalisation coatings selected?

The OEM design is validated by a specific tropicalisation coating.

- Coating of cards in-house.

- Use of a contract manufacturer (CM) to produce to their bill of materials.

The contract manufacturer proposes to do a design-build

- The CM proposes a nomenclature based on its preferred materials and equipment.

Industry specifications determine the design requirements.

- End use of the product requires additional documentation.

- UL 94 In progress

- IPC-CC-830 in progress

Packaging available

- 150 g (6 oz) cartridge in aluminium bag

- 18 kg (5 gallon) pail available

- Sampling available

To sum up

- No added solvents

- No isocyanates

- Fast UV primary curing

- With the addition of secondary moisture, it is a neutral cure

- Adhesion to typical electronic substrates

- Available *Now* in sample cartridges

source : Dow