Guide to the selection of thermal interface materials

Improve the performance and reliability of your electronic design

Why heat is the enemy of appliances

The reasons may vary from application to application. Yet improved thermal management is increasingly essential to maintain the long-term performance and reliability of PCB system assemblies in virtually every industry.

Transportation: From rail to road, vehicles increasingly rely on PCB assemblies for everything from optimising fuel consumption and safety to propulsion and braking. This trend is accelerating and driving demand for more efficient and cost-effective thermal management solutions.

Heat management: The trend towards smaller device sizes with denser components on PCBs is converging with the increased use of flip-chip and stacked-chip architectures. As a result, new thermal management solutions are needed to effectively dissipate heat and ensure greater device reliability.

Solid state lighting: Unlike conventional light sources, the ability to manage the temperature of an LED module has a direct impact on the reliability, output quality, lifetime and system cost of the device. In addition, thermal management is becoming an increasingly important performance metric for the entire LED value chain as solid-state lighting competes with conventional lighting for high intensity and high temperature applications.

Power devices: Power supplies and controls for industry, computer servers and solar and wind power are all handling higher electrical loads and with them increasing temperatures. This trend creates a need for improved thermal management to dissipate the heat in these devices, as this translates into better performance, reliability and lifetime. Improved thermal management also provides the necessary design flexibility.

Consumer devices and telecommunications: Form factor optimisation is one of the challenges facing this industry. Consumer devices are becoming thinner and thinner, which requires compact and multifunctional thermal management solutions.

Why Dow silicones for thermal management?

The inherent versatility of silicone chemistry can help you expand your design freedom, increase your processing options and improve the performance and reliability of your device. As a class of materials, silicones generally offer demonstrable advantages over organic urethane and epoxy solutions, including

- Superior stability and reliability at temperatures ranging from -45°C to 200°C

- More physically robust under mechanical stresses caused by thermal cycling or an inadequate coefficient of thermal expansion.

- Higher elongation and compression for extraordinary protection against shock and vibration

- Greater hydrostability and chemical resistance

- None of the toxicity problems of organic products, thus reducing or eliminating special handling precautions.

- Easier processing, with no need for oven drying or exothermic concerns.

- Stable pot life and ease of reprocessing.

Dow builds on the inherent potential of silicone by combining it with advanced materials knowledge, application expertise, customer collaboration and global presence. The added value we bring is also evident in the unparalleled breadth of our advanced product portfolio, which includes a wide selection of adhesives, compounds, encapsulants and thermally conductive pads – all available in a wide range of delivery formats, viscosities, cure chemistries and thermal and mechanical profiles.

There is likely to be a specific category or grade that offers the optimum processing and performance benefits for your device design. We have designed this guide to help you quickly narrow down your search for a thermal management solution that meets your design goals for heat dissipation, processing and low cost of ownership.

New generation thermal management materials … It’s time!

Dow listens to its customers and continuously innovates product technologies to provide next generation thermal solutions when you need them – today.

Available in a wide range of viscosities and curing chemistries, our thermally conductive materials come in a variety of delivery formats.

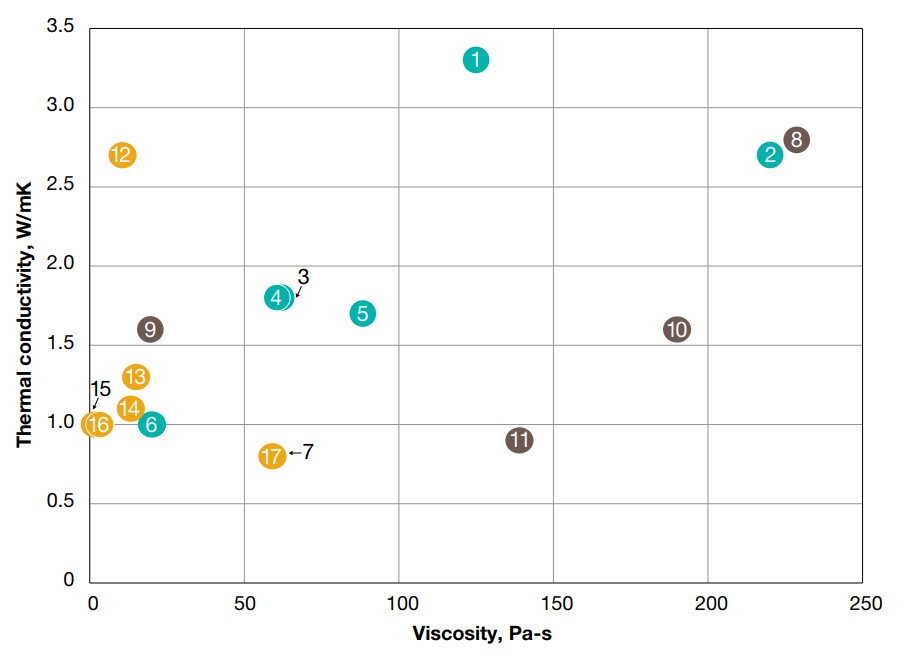

Thermal conductivity as a function of viscosity

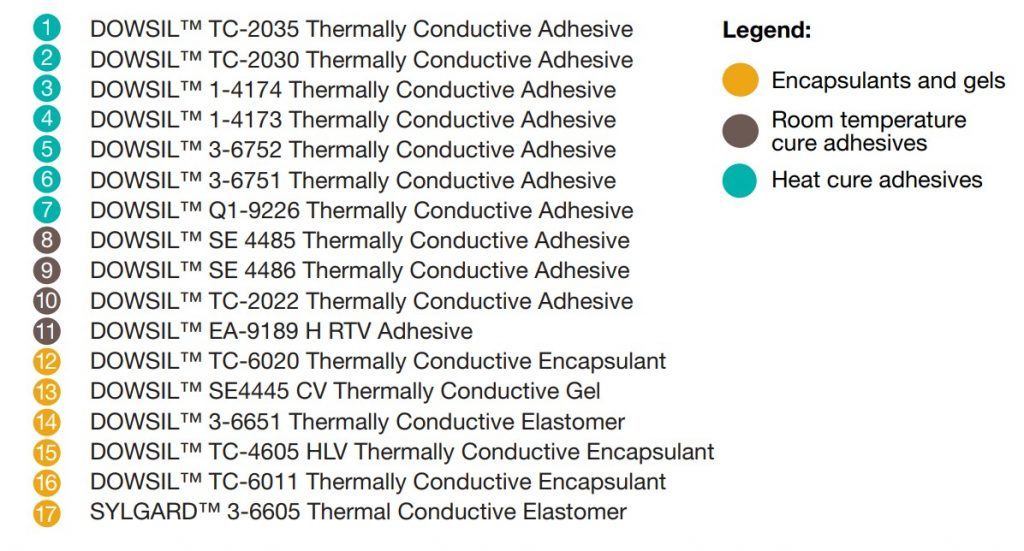

Thermal conductivity as a function of hardness

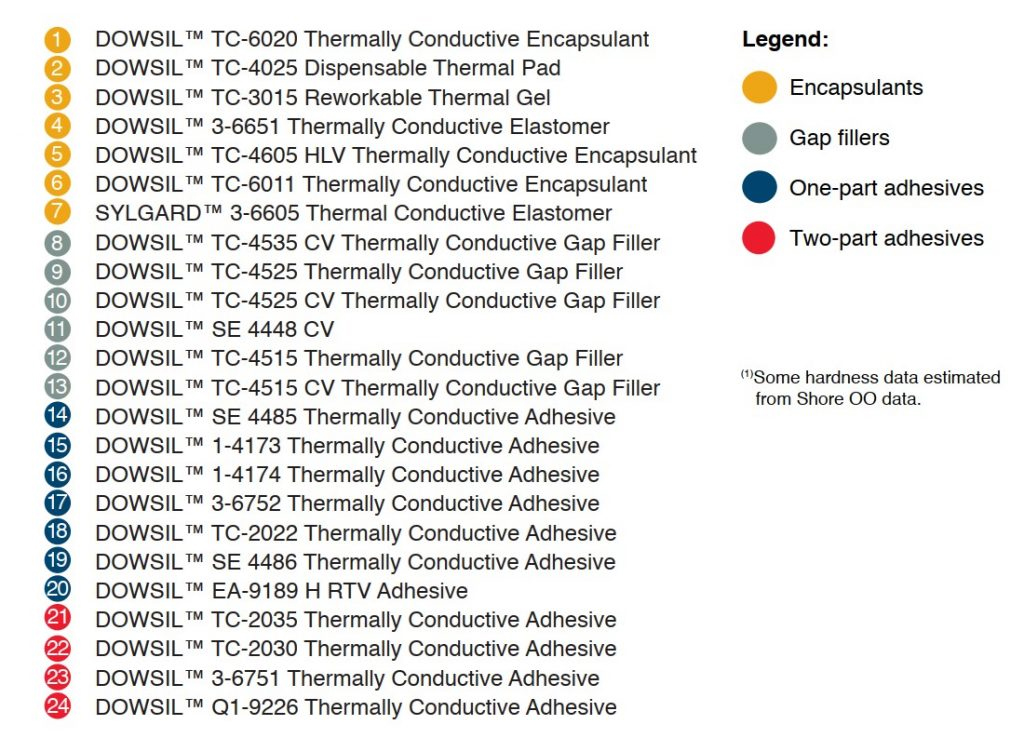

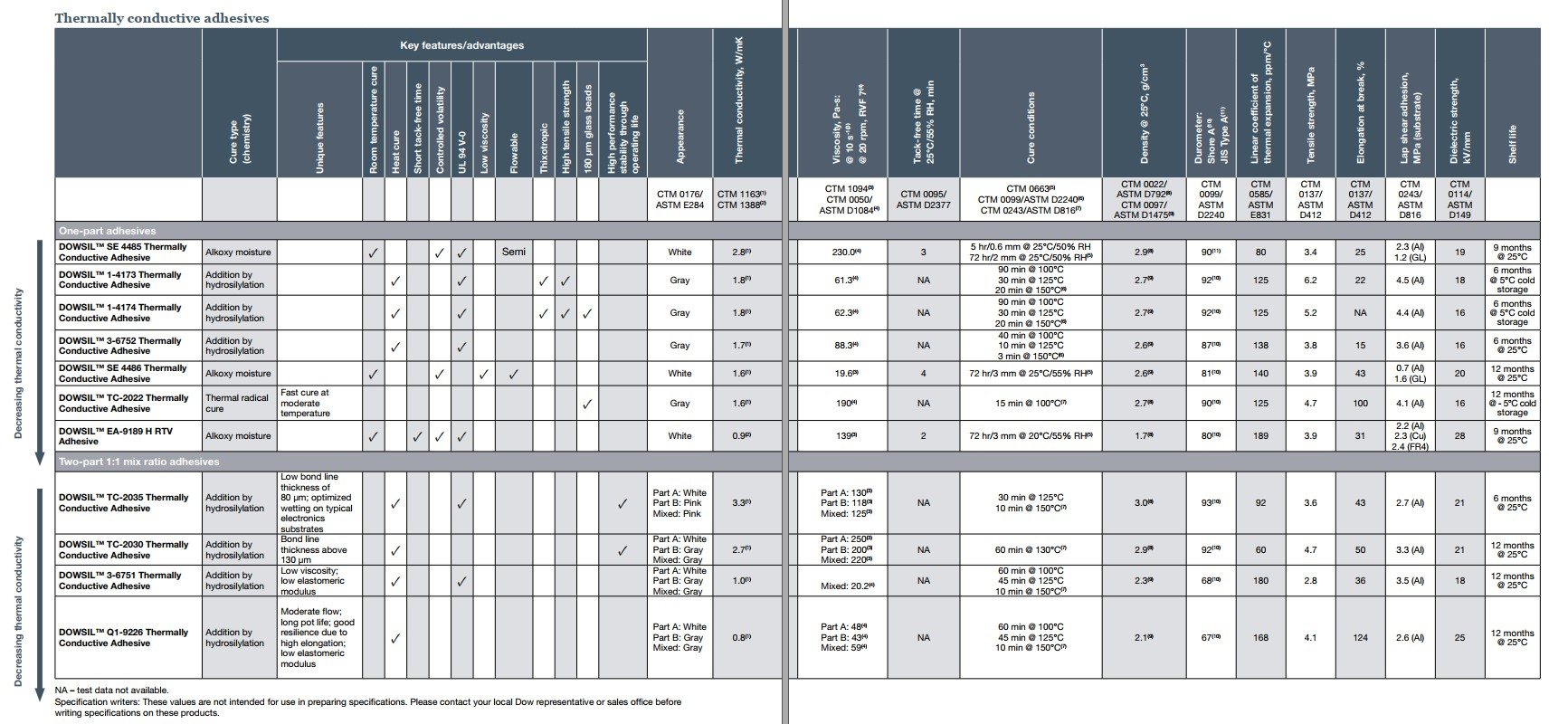

Choose your thermally conductive adhesive

DOWSIL™ thermally conductive silicone adhesives are suitable for bonding and sealing hybrid circuit substrates; semiconductor components; heat spreaders; and other applications that require broad design, flexible processing options and excellent thermal management.

The high-performance materials in our portfolio include moisture-cured grades for simple processing at room temperature, as well as heat-cured solutions to accelerate productivity and time to market. Options range from low viscosity liquids that fill irregularly shaped spaces and ensure large contact areas for maximum heat transfer, to non-sag formulations that maintain the vertical position before curing is complete.

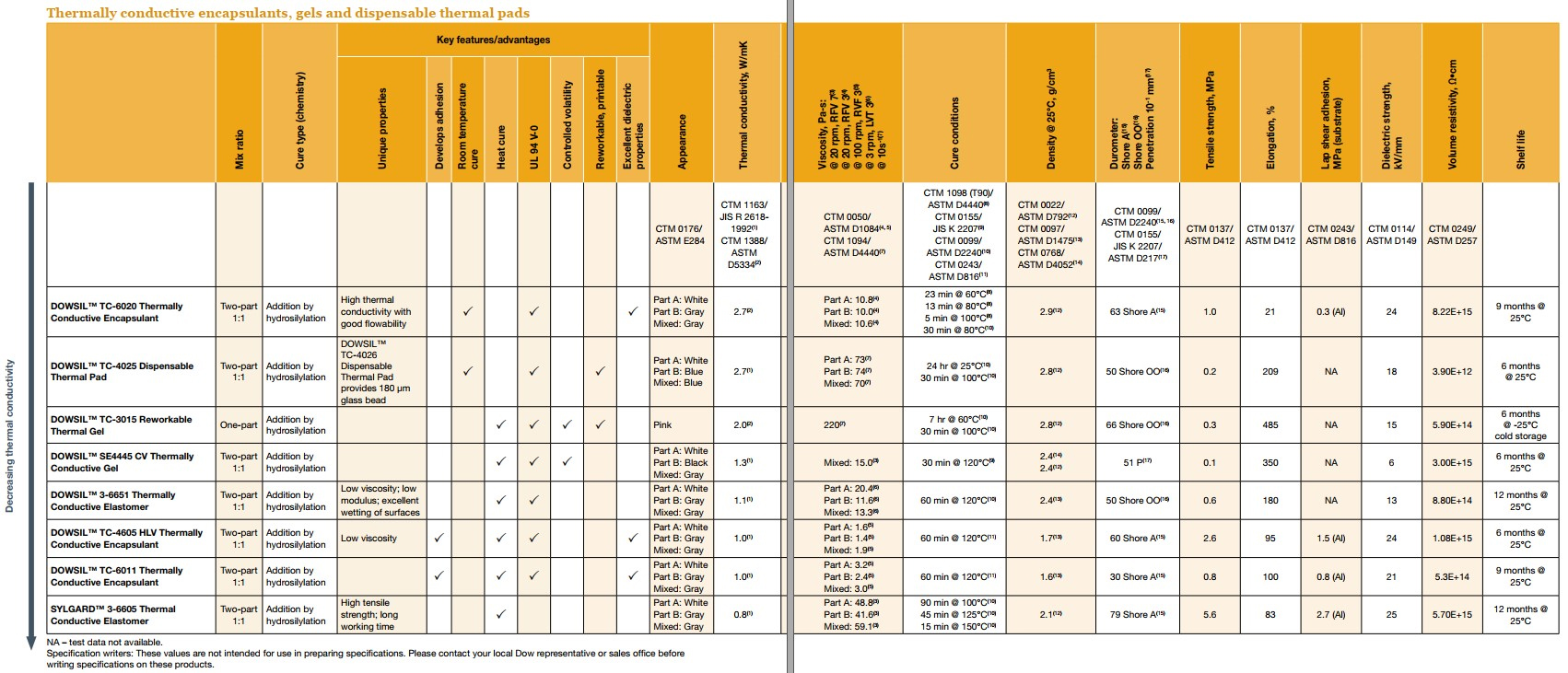

Choose your thermally conductive encapsulant, gel or thermal pad.

Dow’s selection of DOWSIL™ and SYLGARD™ thermally conductive silicone elastomers and gels present flexible options for protecting sensitive components from harsh environmental conditions as well as heat. Offering low viscosity before curing, these products are easily processed and fully integrate large components, delicate wires and solder joints to improve thermal management – even for the most complex structures. In addition, DOWSIL™ thermal pads allow you to quickly and accurately print a thermally conductive silicone compound in controllable thicknesses onto complex substrates.

Silicones in this versatile portfolio include:

- Encapsulants, which come in a variety of viscosities and cross-linking chemistries and cross-link into rubbery elastomers that offer reliable protection against harsh environmental conditions.

- Gels that offer a remarkably low modulus to protect the most sensitive and delicate components from mechanical stress and the effects of thermal cycling.

- Dispensable thermal pads that offer a versatile and cost-effective alternative to prefabricated thermal pads.

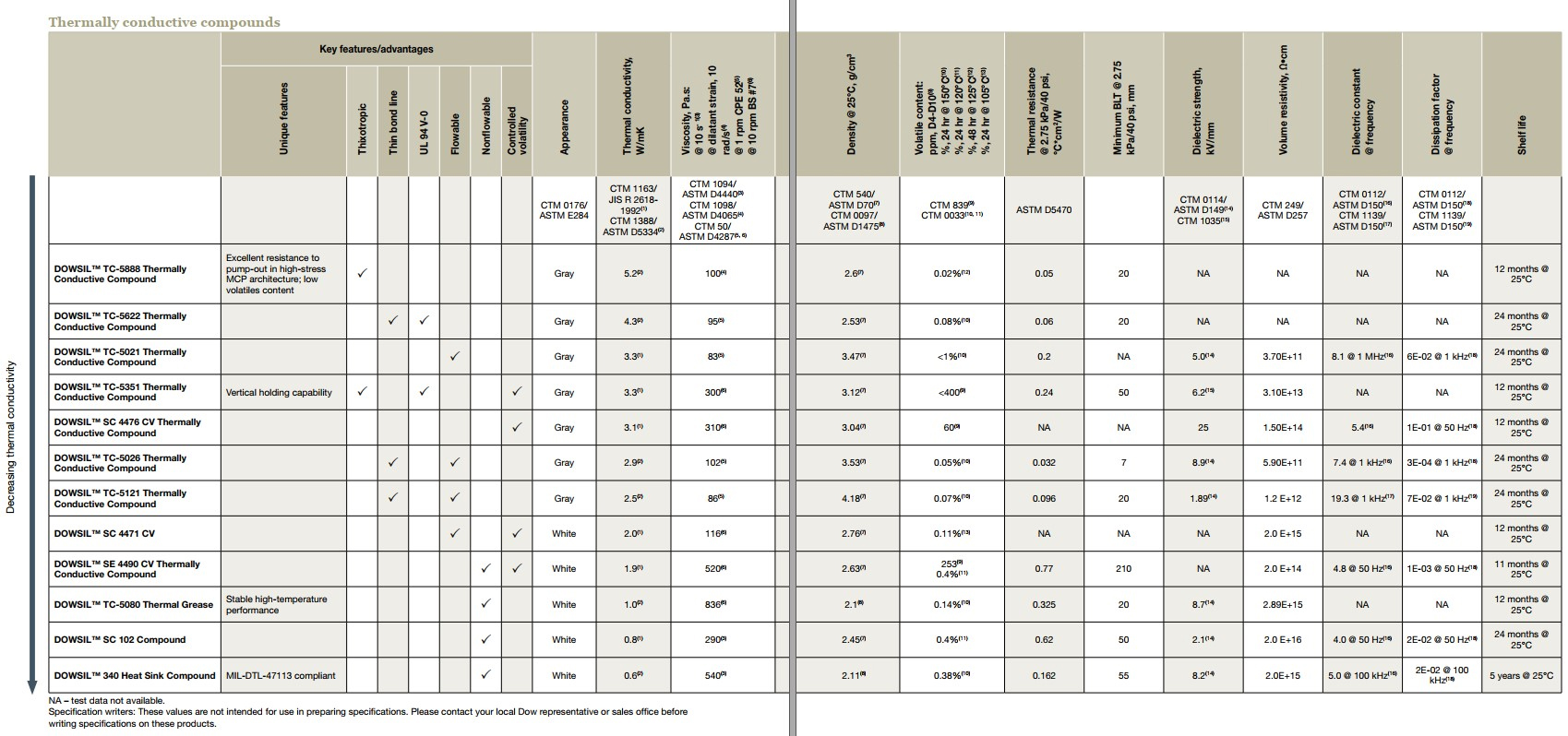

Choose your thermally conductive compound

DOWSIL™ thermally conductive silicone compounds offer high apparent conductivity and low thermal resistance to effectively draw heat away from sensitive PCB components and dissipate it into the surrounding environment. Applied by screen or print processes or standard dispensing equipment, our thermal compounds flow easily to fully cover and fill surface irregularities for maximum coverage. Some grades in this product family offer thermal conductivity of up to 4.3 W/mK.

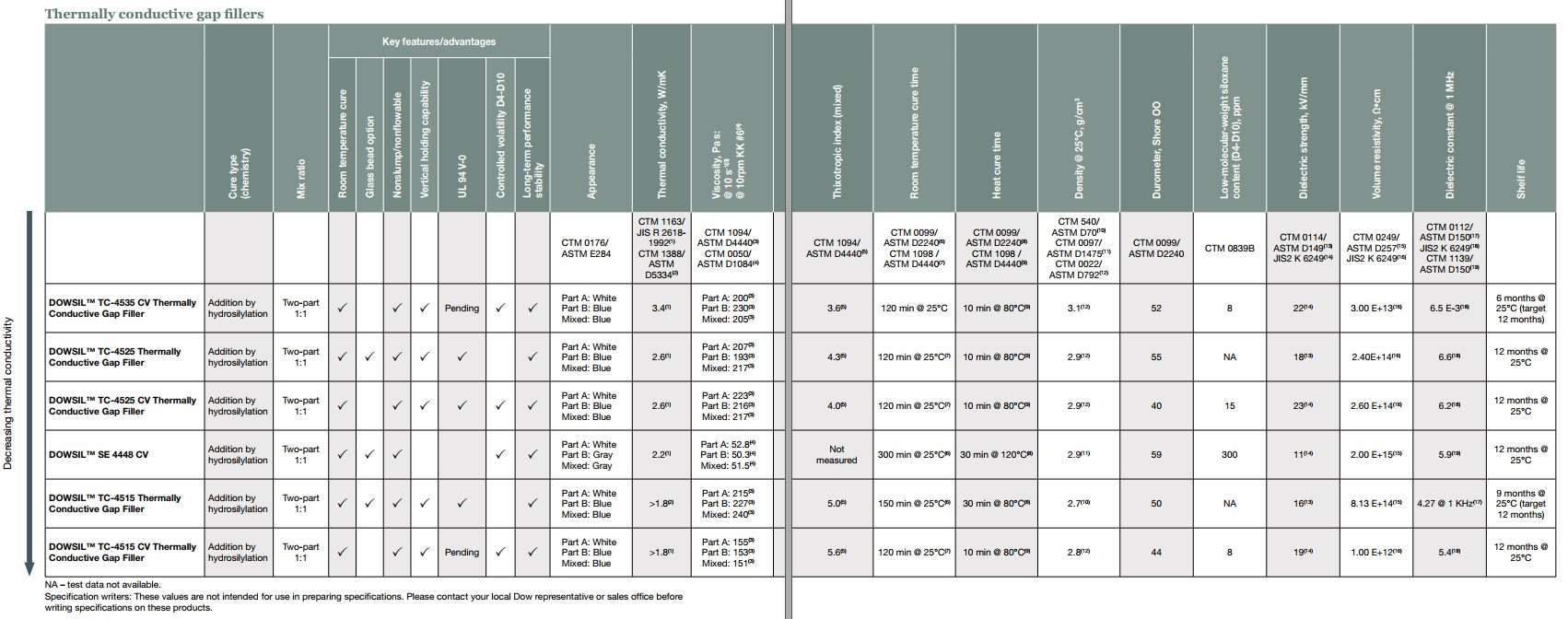

Choose your Gap filler

DOWSIL™ thermally conductive silicone gap fillers are flexible, compressible solutions specifically formulated to convert easily from the original packaging with minimal, if any, additional process preparation. They prevent sagging on vertical surfaces during assembly and retain their vertical stability after curing, even after long use.

These highly advanced silicone formulations dissipate heat from sensitive PCB components by efficiently conducting it to a heat sink. Capable of withstanding a maximum exposure of 200°C, these materials perform reliably at operating temperatures up to 150°C. Our sealants also provide effective vibration damping.

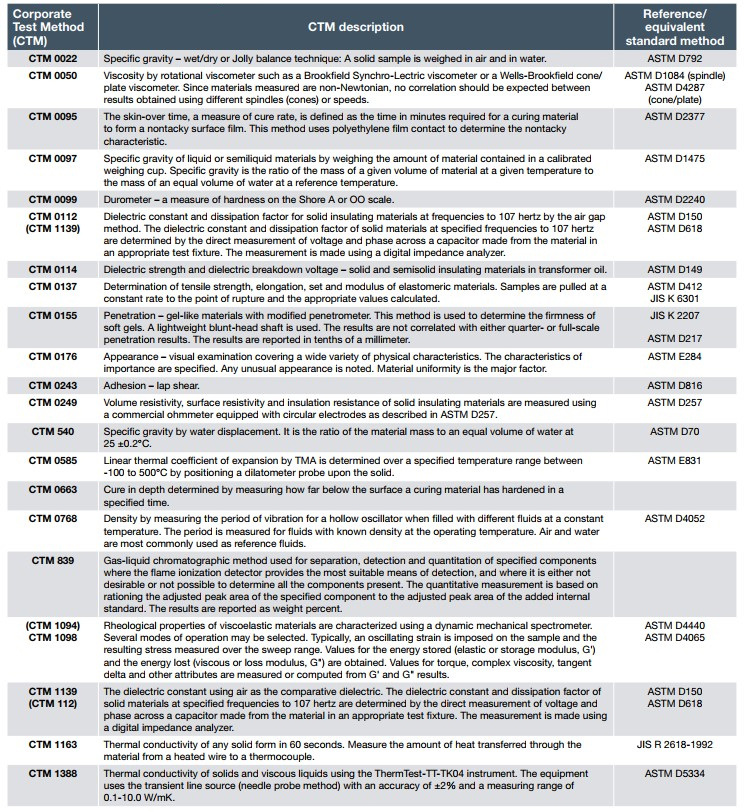

Company test methods and equivalents

More info :

Need information on Dispensable Thermal Pad or on the Dowsil™ brand ? Contact our tecnical service to +33 426 680 680 or fill our contact form.

Samaro also offers other thermal management solutions through its Thermal Management Selection Guide. In this guide you will find our compounds, thermal pads, dispensable pads, thermally conductive encapsulants (RTV & HTV) and thermally conductive adhesives.

Source : dge-europ.com