MOLYKOTE® HP-300 Certified ISO 14687: The Specialty Grease Ensuring Hydrogen Purity in France and Europe

A Concrete Solution to Purity Challenges in Hydrogen Systems

With the rise of hydrogen technologies in Europe, fuel purity has become a critical issue to ensure the performance, safety, and durability of equipment. Refueling stations, fuel cell electric vehicles (FCEVs), pipelines, and high-pressure tanks all require materials that meet extreme compatibility standards.

It is in this context that DuPont™’s high-performance grease MOLYKOTE® HP-300 stands out:

✅ Certified ISO 14687:2019 Grade D

✅ Compatible with high-pressure gaseous hydrogen

✅ Designed to minimize contamination risks

Why is hydrogen purity essential?

Modern hydrogen systems are highly sensitive to even trace levels of contaminants. These impurities—such as hydrocarbons, particles, and reactive gases—can:

- Poison fuel cell catalysts

- Reduce the efficiency of PEM membranes

- Cause failures in valves, seals, fittings, or compressors

- Lead to high maintenance costs and unexpected downtimes

MOLYKOTE® HP-300 is a specialty grease specifically formulated for systems using high-pressure gaseous hydrogen.

MOLYKOTE® HP-300: Grease Engineered for Hydrogen

Formulated with perfluoropolyether (PFPE) oil and a PTFE thickener, MOLYKOTE® HP-300 is designed to meet the extreme demands of hydrogen systems.

Key Technical Specifications

| Property | Value / Benefit |

|---|---|

| Service temperature | -65 °C to +250 °C |

| Chemical base | PFPE + PTFE thickener |

| Outgassing | Very low (suitable for vacuum and ultra-pure hydrogen) |

| Certification | ISO 14687:2019 Grade D |

| Material compatibility | Metals, plastics, elastomers |

| Gas compatibility | Hydrogen, oxygen, solvents |

Unlike conventional lubricants, MOLYKOTE® HP-300 minimizes outgassing and chemical reactions that could contaminate hydrogen.

Real-World Tested and Certified

In 2024, Molykote® HP-300 was tested at the HyCentA Hydrogen Testfield (Austria), a leading European hydrogen test center. The tests simulated Type IV tank filling according to SAE J2601 at 70 MPa.

Laboratory analyses (IMR EI MS & FTIR) showed:

✅ No degradation in hydrogen purity

✅ Full compliance with ISO 14687:2019 Grade D

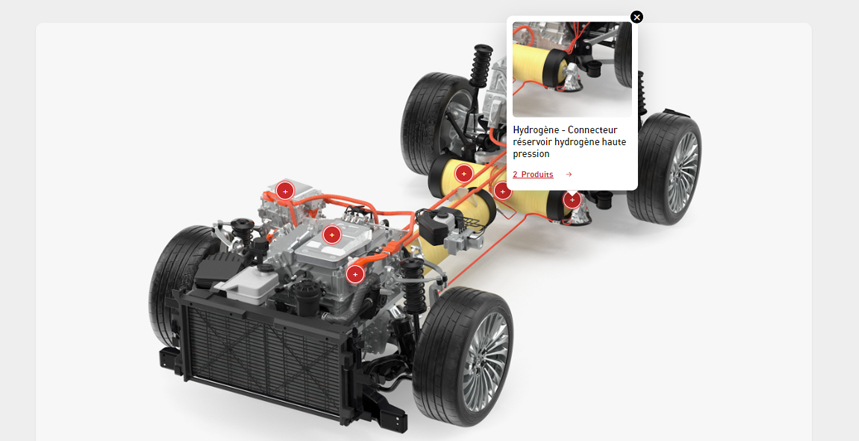

Applications of HP-300 Grease in Hydrogen Systems

MOLYKOTE® HP-300 is used in a wide range of critical applications within hydrogen systems:

- Hydrogen refueling stations: valves, compressors, fittings

- High-pressure tanks (Type IV): O-rings, seals

- PEM fuel cells: actuators, auxiliary controls

- Pipelines: sealing and friction zones

Used especially in refueling stations, Type IV tanks, and fuel cells, HP-300 grease meets the requirements of the most critical hydrogen applications.

Advantages for Hydrogen System Operators and Manufacturers in Europe

For European companies involved in the hydrogen value chain—such as station builders, fuel cell vehicle producers, or industrial equipment operators—MOLYKOTE® HP-300 offers:

✅ Compliance with European and global hydrogen purity standards

✅ Operational safety by reducing catalyst degradation and system failures

✅ Extended service life, reducing maintenance costs and downtime

✅ Versatility in extreme environments due to its chemical resistance and thermal stability

❓FAQ: Is MOLYKOTE® HP-300 compatible with oxygen?

Yes. Its PFPE-based formula provides excellent oxidation stability and low volatility, even in oxygen-rich environments.

Can it be used in cryogenic conditions?

Yes. It remains effective from -65 °C to +250 °C, making it ideal for extreme applications.

What standards does it meet?

- ISO 14687:2019 Grade D (hydrogen purity)

- SAE J2601 (filling conditions)

Where can I get it?

From Samaro, the official MOLYKOTE® distributor in France. Contact our technical team for support.

In Summary: The 5 Key Benefits of MOLYKOTE® HP-300

- Certified ISO 14687:2019 Grade D

- Compatible with hydrogen, oxygen, and solvents

- Extreme thermal range: -65 °C to +250 °C

- Field-tested by HyCentA under real-world conditions

- Ideal for H₂ stations, fuel cells, and pipelines