How Krytox™ Lubricants Minimize NVH in Electric Vehicle Interiors

The electric vehicle (EV) revolution is in full swing, reshaping the future of transportation. As internal combustion engines give way to cleaner electric powertrains, manufacturers face new challenges in crafting a premium driving experience. One significant hurdle is managing noise, vibration, and harshness (NVH), which has become a critical aspect of EV design and performance.

In EVs, the quiet hum of electric motors eliminates the masking effect of traditional engine noise, making even subtle sounds like cabin rattles, squeaks, and vibrations far more noticeable. Addressing NVH isn’t just about comfort—it’s about ensuring the vehicle meets consumer expectations for quality and refinement. Enter advanced lubricants like Krytox™, which offer innovative solutions for NVH reduction.

What Is NVH, and Why Does It Matter in EVs?

NVH stands for Noise, Vibration, and Harshness, encompassing the auditory and tactile sensations experienced by passengers inside a vehicle. In traditional cars, the engine’s roar often overshadows smaller sounds. However, the near-silent operation of EV motors highlights noises from other components—such as squeaky doors, rattling plastics, or buzzing electronics—potentially detracting from the serene experience consumers expect in electric vehicles.

Addressing NVH is especially crucial for EVs aiming to provide a luxury-like driving experience. It’s no longer just about transportation; it’s about creating an environment of quiet, comfort, and sophistication.

Key NVH Challenges in Electric Vehicles

Several factors contribute to NVH in EV interiors:

- Moving Components: Door hinges, latches, and seat tracks can generate noise over time due to friction and wear.

- Plastic Interactions: Lightweight materials like plastic are prevalent in EVs to enhance energy efficiency. However, plastic-on-plastic contact often produces squeaks or creaks.

- Weatherstripping and Seals: Door and window seals degrade with time, allowing air and vibration to enter the cabin.

- Electronic Vibrations: With EVs relying heavily on advanced electronic systems, vibrations from these components can propagate through the structure, creating background noise.

How Krytox™ Lubricants Address NVH in EVs

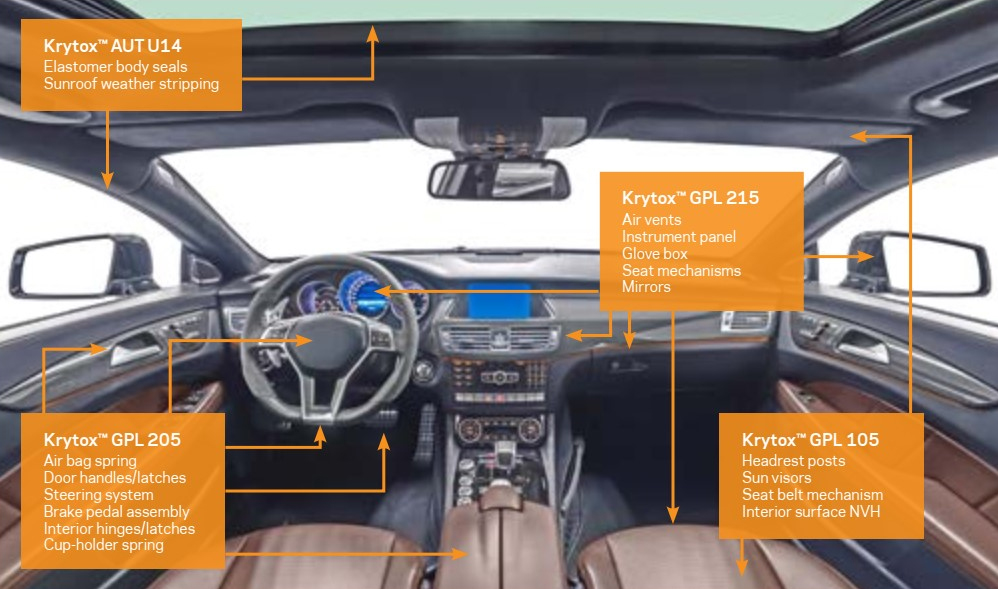

Krytox™ lubricants stand out for their ability to minimize NVH by delivering exceptional performance across a range of interior applications. Known for their thermal stability, low volatility, and compatibility with diverse materials, Krytox™ lubricants are engineered to enhance the longevity and functionality of EV components while reducing unwanted noise.

1. Reducing Noise in Hinges, Latches, and Tracks

Friction is a primary cause of NVH in moving parts. Krytox™ lubricants provide durable lubrication for high-use components like door hinges and seat tracks. By reducing metal-on-metal and metal-on-plastic friction, these lubricants eliminate squeaks and rattles, ensuring a smooth, silent operation.

2. Eliminating Squeaks from Plastic Components

With the shift to lightweight plastic materials in EV interiors, friction-induced noises can become a constant nuisance. Krytox™ lubricants excel in reducing plastic-on-plastic squeaks by creating a stable, low-friction barrier. Their compatibility with elastomers ensures long-term effectiveness without damaging materials.

3. Preserving Seals for a Quiet Cabin

Door and window seals are essential for keeping noise, air, and water out of the cabin. Krytox™ lubricants enhance the elasticity and durability of these seals, preventing degradation that could lead to air leakage and noise ingress. This results in a tighter, quieter interior.

4. Dampening Vibrations from Electronics

As EVs feature extensive electronic systems, vibrations from these components can generate background noise. Applying Krytox™ lubricants to connectors and electronic assemblies reduces vibration propagation, creating a more acoustically refined cabin.

The Long-Term Benefits of Krytox™ for EVs

Investing in Krytox™ lubricants goes beyond NVH reduction—it offers a range of advantages for manufacturers and end-users alike:

- Extended Component Lifespan: Krytox™ lubricants resist extreme temperatures, oxidation, and wear, ensuring long-lasting performance and reducing the need for frequent replacements.

- Lower Maintenance Costs: With their durability, these lubricants require less frequent re-application, lowering maintenance demands while providing continuous NVH mitigation.

- Enhanced Driver Satisfaction: By delivering a quieter, smoother ride, Krytox™ lubricants elevate the overall driving experience, fostering customer loyalty and enhancing brand reputation.

Why NVH Optimization Matters for EV Success

In the competitive EV market, where consumers are drawn to both innovation and luxury, managing NVH is a decisive factor. A quiet cabin free from intrusive noises isn’t just a nice-to-have—it’s an expectation for the modern EV driver. Krytox™ lubricants help manufacturers meet and exceed this expectation by addressing the root causes of NVH with cutting-edge technology.

Conclusion: Driving the Future of EV Comfort

The EV revolution demands innovation at every level, from propulsion systems to passenger comfort. By leveraging the high-performance capabilities of Krytox™ lubricants, manufacturers can significantly reduce NVH, delivering the premium, quiet interior that today’s EV buyers desire. As the industry continues to evolve, solutions like Krytox™ are not just enhancements—they’re essential for driving the next generation of electric vehicles forward.

Investing in advanced NVH solutions is more than just good engineering; it’s the key to creating a truly enjoyable and sustainable driving experience.