Innovative EMI Shielding Solutions with Conductive Paints from MG Chemicals: Overcome Electromagnetic Interference Challenge

Are you a product designer, manufacturer, or engineer grappling with electromagnetic interference (EMI)? Ensuring electromagnetic compatibility (EMC) has become crucial across industries like electronics, automotive, and communications. To address this, MG Chemicals is hosting a webinar on November 25 at 1:00 PM GMT, where experts will explore cutting-edge solutions, including the use of conductive paints. This event is a must for anyone looking to enhance product compliance and performance through innovative EMI shielding techniques.

Why EMI is a Significant Challenge in Today’s Industry

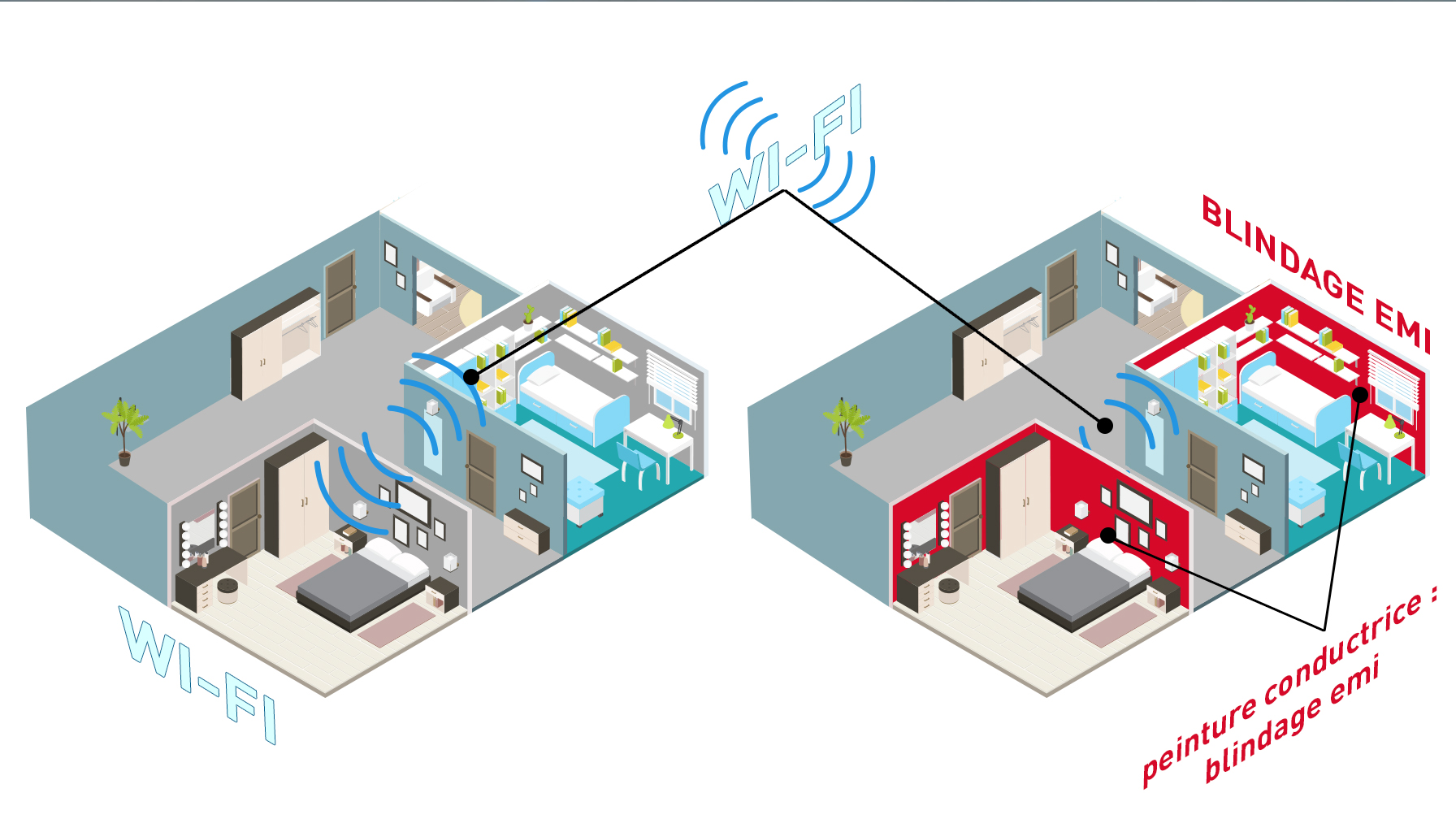

EMI is an electrical disturbance generated by one device or circuit that interferes with the operation of other electronic devices. This interference can disrupt communications, compromise equipment safety, and lead to costly malfunctions. MG Chemicals’ EMI solutions address these issues effectively by offering shielding products, especially conductive paints that protect devices while facilitating the manufacturing and design process.

MG Chemicals’ Conductive Paints: The Innovative Solution

The conductive paints developed by MG Chemicals meet the growing need for EMI shielding across industries such as automotive, consumer electronics, and telecommunications. These paints are formulated to provide optimal protection while enabling easy and rapid application. Unlike traditional shielding methods, conductive paints can be directly applied to the product, offering greater design flexibility and easy adaptation to various surfaces and materials.

Key Advantages of MG Chemicals’ Conductive Paints

- Superior Shielding Effectiveness: Our conductive paints provide high-performance EMI shielding across a wide frequency range, protecting devices from both internal and external interferences.

- Simple and Fast Application: Unlike metallic shields, conductive paints don’t require complex processes or thermal curing. This allows for faster application and reduced manufacturing costs.

- Versatile Adhesion: Whether applied to plastic, wood, metal, or other substrates, our conductive paints ensure reliable, durable adhesion across various materials without sacrificing effectiveness.

- Eco-Friendly Solutions: With environmental considerations in mind, we offer low-VOC formulations, providing effective shielding while reducing ecological impact.

Technical Properties of Conductive Paints: What Makes Them Stand Out

The formulations in MG Chemicals’ conductive paints incorporate innovative materials to offer optimal electrical conductivity while ensuring a robust EMI shield. Here are some technical aspects that set our paints apart:

- Formulations for EMI Shielding: Each formulation is designed to maximize electrical conductivity and durability, offering reliable protection even in demanding environments.

- Durability and Resilience: Our paints are built to withstand mechanical stresses and harsh environmental conditions, making them ideal for industrial and commercial applications.

- Customizable Options: We offer paints tailored to the specific needs of each project, whether for high-precision devices or large-scale shielding solutions.

Industrial Applications: Where and How to Use MG Chemicals’ Conductive Paints

MG Chemicals’ conductive paints are useful across a wide range of sectors. Here are some examples where our EMI solutions are particularly effective:

- Automotive: In the automotive industry, communication and safety systems are often vulnerable to interference. Our paints ensure reliable shielding, enabling interference-free communication and enhanced safety.

- Consumer Electronics: Devices such as TVs, smartphones, and smart home systems are especially sensitive to interference. Our paints provide effective shielding without adding weight and are compatible with modern designs.

- Telecommunications: For data transmission equipment, reliable shielding is essential to ensure high-quality signal strength. MG Chemicals’ conductive paints help maintain stable connections and minimize signal loss.

Why Choose MG Chemicals for Your EMI Shielding Needs?

Choosing MG Chemicals means opting for EMI shielding solutions created by industry experts with decades of expertise. We understand the varied needs of our clients and have developed conductive paints that deliver clear advantages in performance, durability, and flexibility. Here’s why we are the preferred choice for multiple sectors:

- Commitment to Quality and Compliance: Our products meet the highest quality standards, guaranteeing effective and lasting EMI protection.

- Invaluable Expertise: With a team of researchers and developers, we stay at the forefront of EMI shielding innovation, offering solutions tailored to emerging technologies.

- Personalized Support: At MG Chemicals, we offer a customized approach to each project, ensuring that every product benefits from the most appropriate EMI shielding solution.

Register for Our Webinar to Discover Our Solutions

To better understand how MG Chemicals’ conductive paints can meet your EMI shielding needs, don’t miss our webinar on November 25 at 2:00 PM CET. This event is the perfect opportunity to learn about our products, ask questions of experts, and receive practical advice for effectively integrating our solutions into your projects.

Conclusion: Give Your Products a Competitive Edge with MG Chemicals’ Conductive Paints

MG Chemicals’ conductive paints are an innovative answer to modern EMI challenges, offering an effective shielding solution that is easy to apply and environmentally friendly. By choosing our solutions, you’re opting for performance, reliability, and flexibility, all backed by top-tier technical expertise. Register for our webinar today to learn how our solutions can transform your projects and ensure the electromagnetic compliance of your products.